China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Jushi Fiberglass Chopped Strand Mat Supplier

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

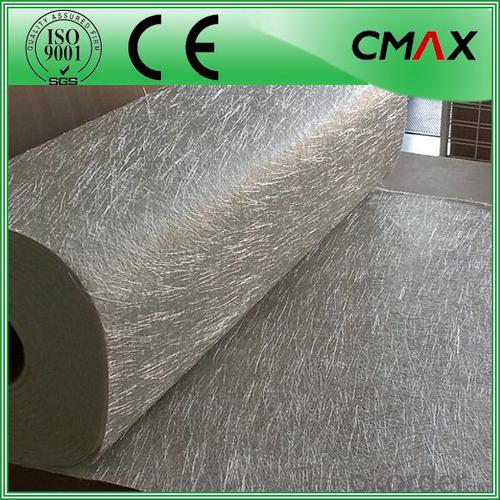

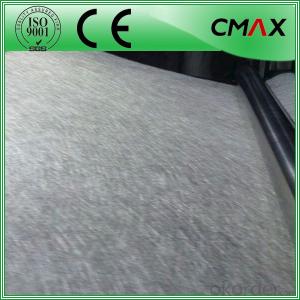

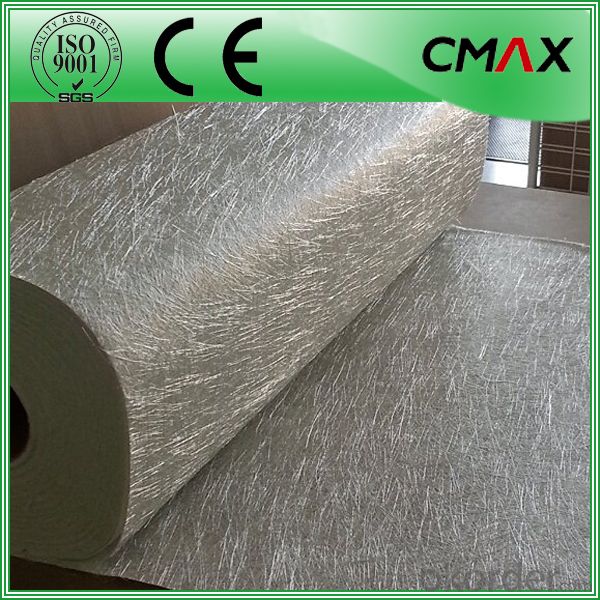

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: This question asks for an explanation of the various methods used in the manufacturing process to produce black fiberglass tissue.

- <p>Black fiberglass tissue is typically produced through a series of manufacturing processes that involve the use of glass fibers and resins. The primary methods include: 1) The wet lay-up process, where glass fibers are soaked in a resin solution and then layered to form the tissue. 2) The spray-up process, where resin and chopped glass fibers are sprayed onto a mold and allowed to cure. 3) The hand lay-up process, which is similar to wet lay-up but involves manually applying the resin and fibers. 4) The pultrusion process, where fibers are pulled through a resin bath and then into a heated die to form the desired shape. 5) The filament winding process, where continuous glass fibers are wound around a rotating mandrel to create a strong, uniform tissue. Each method has its own advantages and is chosen based on the specific requirements of the end product, such as strength, flexibility, and cost.</p>

- Q: Is fiberglass facing resistant to moisture or water damage?

- Yes, fiberglass facing is resistant to moisture and water damage.

- Q: This question asks about the ease of cleaning black fiberglass tissue.

- <p>Black fiberglass tissue is relatively easy to clean, but it requires some care. It can be wiped down with a damp cloth and mild detergent to remove dirt and grime. However, avoid using harsh chemicals or abrasive materials as they can damage the surface. Regular cleaning helps maintain its appearance and longevity. It's also important to dry the surface thoroughly after cleaning to prevent any water damage or mold growth.</p>

- Q: This question asks for advice on how to maintain the cleanliness and integrity of black fiberglass tissue.

- <p>To prevent your black fiberglass tissue from getting dirty or damaged, follow these tips: 1. Keep it covered when not in use to avoid dust and dirt accumulation. 2. Use a soft, damp cloth to gently clean the surface, avoiding harsh chemicals that could damage the material. 3. Store it in a cool, dry place away from direct sunlight to prevent fading or warping. 4. Handle the tissue with clean hands or use gloves to avoid transferring oils or dirt. 5. Regularly inspect for any signs of wear or damage and address them promptly to prevent further deterioration. By taking these precautions, you can prolong the life and maintain the appearance of your black fiberglass tissue.</p>

- Q: The user is asking if they can repurpose lint from their dryer to create homemade black fiberglass tissues.

- <p>No, you cannot use dryer lint to make black fiberglass tissues. Dryer lint is composed of fibers from clothing and other materials, which are not the same as the glass fibers used in fiberglass production. Fiberglass is made from fine filaments of glass that are combined with a resin to form a composite material. It requires specific manufacturing processes and materials that are not present in dryer lint. Using dryer lint for this purpose would not yield the desired strength, durability, or properties of fiberglass tissues.</p>

- Q: What are the ecological effects associated with the utilization of black fiberglass tissue?

- <p>The environmental impact of using black fiberglass tissue is primarily associated with its production and disposal. During production, it can release harmful chemicals and particulates into the air, contributing to air pollution. Additionally, fiberglass is not biodegradable, which means it persists in landfills and can leach chemicals into the soil and groundwater, potentially harming ecosystems. The dark color of black fiberglass may also absorb more heat, which could contribute to the urban heat island effect. However, it's important to note that the environmental impact can be mitigated through proper waste management and recycling programs, which are becoming more prevalent as awareness of environmental issues grows.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside buildings.

- <p>Black fiberglass tissue, commonly used as insulation, can affect indoor air quality if not properly installed or if it becomes damaged. Fiberglass releases tiny glass fibers into the air, which can be inhaled and cause respiratory irritation, allergies, or even more severe health issues over time. Proper installation and sealing can minimize the release of these fibers. Additionally, ensuring good ventilation in buildings can help reduce the concentration of airborne fibers. It's also important to follow safety guidelines when handling fiberglass to prevent exposure.</p>

- Q: China's glass fiber product code is what?

- The code name of the song, for example, the order: ???????????? C C 8-36 × 2 × 3 S 110 ???????????????????????????????????? Twist (twist / m) ???????????????????????????????????? Twist ???????????????????????????????????? And twist the number of shares ???????????????????????????????????? Number of shares released ???????????????????????????????????? Original yarn density (g / 1000m) ???????????????????????????????????? Single fiber nominal diameter (m?) ???????????????????????????????????? Continuous glass fiber ???????????????????????????????????? Alkaline glass fiber Description: ① twist to S that the right twist, Z said left twist:

- Q: What are the recommended brands for black fiberglass tissue used in various applications?

- <p>There isn't a universally recommended brand for black fiberglass tissue as the choice often depends on specific application needs, quality requirements, and regional availability. However, some well-known brands in the composite materials industry that offer fiberglass tissues include Owens Corning, Hexcel, and SGL Group. These companies are recognized for their high-quality products and have a broad range of applications in industries such as aerospace, automotive, and construction. It's advisable to consider factors like product specifications, cost, and customer reviews when selecting a brand for black fiberglass tissue.</p>

- Q: The user is asking if they can use old paper towels as a replacement for black fiberglass tissues in a situation where they don't have the latter available.

- <p>While it might be tempting to use old paper towels as a substitute for black fiberglass tissues, it is not recommended. Paper towels lack the strength and durability of fiberglass tissues, which are specifically designed for certain applications due to their heat resistance and insulation properties. Using paper towels could lead to ineffective insulation, potential fire hazards, or structural failure. It's best to use the appropriate materials as specified to ensure safety and effectiveness.</p>

Send your message to us

China Jushi Fiberglass Chopped Strand Mat Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords