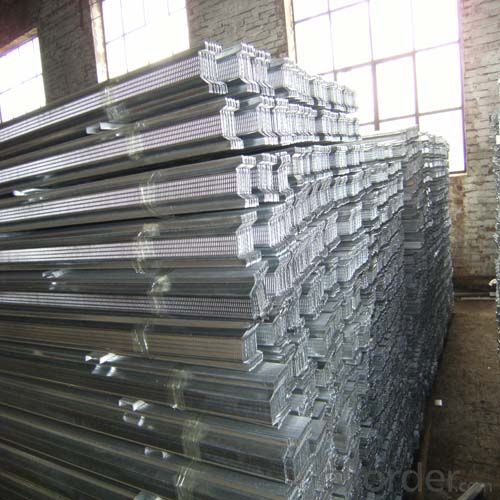

China Drywall Partition Metal Stud Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Advantage and feature:

1.Light, good strength, cauterization resistance and water resistance

2.Matching magnesium fire-proof board, gypsum board and many other walll and ceiling board

3.Moisture-proof, shock-resistance, environment-friendly and so on.

4.Easy and fast for install, time-saving

5.High quality, competitive price and complete sets of style

6.We can supply you the products based on your specific requirements

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Light steel keel gypsum board system is usually double-sided wall structure, that is, "plate - keel (cavity) - plate" structure, each side of the wall board for the single or double gypsum board, Light steel keel. In order to obtain better sound insulation effect, in the cavity filled with rock wool board or glass wool.

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- But this will be more expensive construction costs

- Q: Light steel keel wall waterproof

- 1. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) Used for bonding with the substrate, to achieve 100% continuous sticky. 2. Use 1032 to enhance the polyester cloth Used to enhance the coating of tensile, tear resistance and fatigue resistance. 3. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) By enhancing the gap of the mesh structure of the polyester cloth, the intermediate layer and the base coating are fully infiltrated and integrated to effectively enhance the sealing performance of the coating. 4. Use steel coated excellent 1021 metal roof dedicated high-elastic waterproof coating (surface)

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- Lightweight wall material gypsum block.It has the characteristics of light weight, high strength, good durability, accurate size, smooth surface, no cracking, fire protection, good heat insulation effect, and good respiratory performance and good sound insulation. Widely used in buildings, hotels, entertainment centers, street walls of the wall partition. It is easy to build, a wall into the installation of fast, soundproof, fire, ecological, for non-load-bearing wall, multi- Alternative light steel keel, is a substitute for paper gypsum board decoration partition upgrade, cost-effective, market advantage. Can be combined within the partition wall, sub-wall and wall from the insulation, etc., played a variety of material advantages, a variety of combinations, insulation energy, sound insulation, fire, light, easy assembly, low cost, market space.

- Q: Light steel keel wall in the end is how much money to know

- The partition depends on whether you are single or double-sided single-sided 30 a square double-sided 50 a square called 70 are cut your gypsum board has 13 to 23 blocks have you do partition And not good gypsum board as long as 14 to 15 pieces of gypsum board on it

- Q: Light steel keel wall and wood which low cost

- If you are in the home decoration inside the words, the cost of this level is negligible. And if the area is relatively large, then the use of light steel keel production wall, there will be a clear advantage. Light steel keel production of the wall, its performance is relatively stable, wood products can not be compared.

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- Can ah, the paper gypsum board above also scraping putty ah, the workers will deal with, you just ask the request on it, professional things professional do

- Q: Curved gypsum board wall technology.

- Curved (sub-bumps) of the construction method: the first with the blockboard to make the first arc, in the right place with keel (wood keel, light steel keel can be) to shape the joinery board, and then gypsum board Attached to the blockboard and keel on the line. The following figure is the arc (concave) top of the grass-roots approach, curved wall practice with it the same.

- Q: With light steel keel gypsum board do partition wall price how to count?

- Double-sided labor costs more than 20 yuan per square meter, the material to see the grade of gypsum board and the thickness of the keel. Generally not more than 20 yuan per level. Plus freight and handling costs, loss. Offer 60 yuan per flat can be.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Focus on the ground material, the first floor of the plant decoration if the ground, a lot of plant floor decoration is not required to carry the load, then you can consider using some inexpensive decorative materials, such as terrazzo or cement flooring to do the plant floor decoration materials, Decoration to consider anti-static, then we should choose anti-static floor or anti-epoxy floor, etc. as the preferred material for the ground, there are plant floor decoration needs to load the ground, then we must do concrete in the ground floor, Concrete is divided into commercial concrete and soil concrete two, the former cost slightly higher but the quality is stable, the latter price lower quality in general, and then in the concrete base and then lay the other texture is more hard stone finishes can be.

Send your message to us

China Drywall Partition Metal Stud Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords