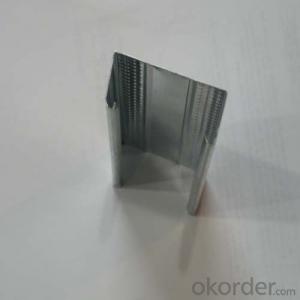

CE Approved Drywall Partition Metal Stud Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Item | Specification (mm) | |

Width | Height | |

V channel | 30/38 | |

Main channel | 38 | 10/12/14 |

Main channel | 50 | 12/15 |

Cross channel | 50 | 15/17/19 |

Cross channel | 60 | 27 |

Cross channel | 38 | 27 |

Furring channel | 35 | 22 |

U angle | 29 | 24/29 |

L angle | 22-35 | |

Track /Horizontal Channel | QU/UW | 50/75/100x35/40/50x0.45mm |

Stud/Vertical Channel | QC/CW | 50/75/100x35/40/50x0.45mm |

Omega Furring Channel | Ω | 35x22x12/13mm |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- What brand to see it? Four brands are more expensive. Generally in the 7.5-9.5 a meter In the high-end 4.5-6.5 yuan / m

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Now home improvement wall materials are generally light steel keel + sound insulation cotton and light brick wall two, two have their own advantages and disadvantages, brick wall thickness, and space, sound insulation and no sound insulation board is good ; Light steel keel plus gypsum board cut off the knock will be pound, but if it is to consider the bedroom wall after the TV, then the best use of light steel keel + noise cotton, because the hanging must be hanging on the keel, or hanging The In addition, can also be resistant to sound insulation board, thinner board sound insulation effect is better, but the price is relatively expensive. General high noise requirements such as the hotel is used in such a soundproof board.

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q: Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q: Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q: How to remove the gypsum board cut off

- To deal with the local property, to understand the removal of the area to be noted, such as the demolition of the mall will be sealed room, so that the impact of dust and garbage next door store business. And the parties to deal with more, will facilitate the back of the work.

- Q: Can the gypsum board be painted on the wall

- If the light can be linked to the screw with a self-tapping screw, hanging 2-3 kg should be no problem

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- First cut off, after the cut off does not matter. Fixed the problem to your decoration workers. No headache. The First cut off, after the ceiling so that when the ceiling of the wall at the top of the site good handling. Cut off the height of more than 3 meters a few centimeters on it.

Send your message to us

CE Approved Drywall Partition Metal Stud Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords