Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Automatic Straight Edge Banding Machine

1). Automatic edge banding machine, with functions of gluing, pressing, cutting, end cutting, fine trimming, scraping, buffing .

2). Its structure is compact and have a reasonable disposition. It works steadily and operates safely.

3). It adopt the imported original electrical machinery, each performance is better.

4). It is adjustable. The machine adopts the devices of sound insulation, controlling of dust, prevent the overloading, auxiliary frame electrical adjusted.

5). Blow up and down the side, surface polishing up and down and so on.

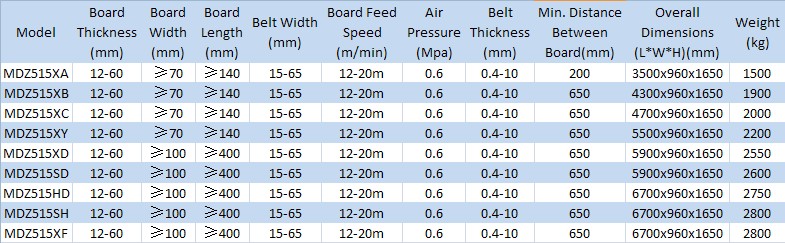

Specification of Automatic Straight Edge Banding Machine

Advantages of Automatic Straight Edge Banding Machine

1). Trim equipment with double trim-blades works on the waved effect that is caused by precise dimersicen saw.

2). The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

3). End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

4). Rough/fine trimming mechanism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly.

5). Profiling unit, to make board end smooth and aesthetic.

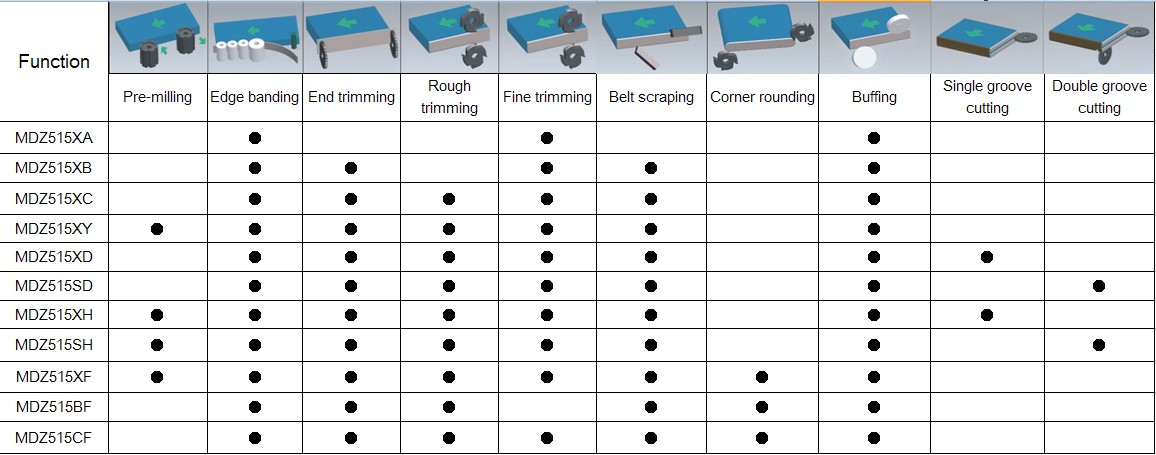

Main Functions of Automatic Straight Edge Banding Machine

Packing of Automatic Straight Edge Banding Machine

- Q: What edge does solid wood cabinet use?

- If it is log, good wood does not use edge banding. Of course, can also use the line edge.

- Q: How to seal the homemade panel furniture?

- There are special hand sealing adhesive, evenly coated on the edge of the plate and sealing band, and can be ironed with an iron, and then hand trimmed

- Q: Sealing process of furniture integral wardrobe

- Hello, there are full automatic edge banding machine and manual edge sealing machine 2, general small factory is made of about 100 thousand of the automatic edge sealing machine, manual edge sealing machine is used to seal the irregular edge. After adjusting the machine, directly put the board on the seal, you can, after the seal can repair side repair color, but the panel furniture is to see the edge, the edge is good, it can also sell a good price. Talk to me, jeanspi whole wardrobe.

- Q: Cross stitch edge ornaments how?

- The embroidered figure leaves two or three, the rest are cut off, and then put two pieces of the same can repair the suture, suture when in fact it is best not to use the fishing line, because it is not just the line Yuntie, with cotton, nice and strong, the color edge of cotton to choose if you stitch, is cluttered with black or white, you try, definitely better than the suture line.

- Q: Are there any big differences between semi-automatic edge banding and full automatic edge sealing?

- The effect varies greatlyIt's like handguns and tanks. Which one is so powerful?Effect, efficiency is incomparable

- Q: Who knows in the ambry, what does the edge banding of lacquer paint panel have? Which kind is commonly used in the market? Thank you

- The real paint door does not need edge banding.There is a kind of UV board, also known as baking paint, aluminum edge is used.Edge is good or bad, mainly depends on whether it is easy to fall off, not only with the edge material, but also closely related to the glue and process.

- Q: Where is the construction of the unsupported end plate in the 11G101-1P95 page?

- The question is worth exploring

- Q: What is the best glue for solid wood sealing?

- Do you have to see by hand or mechanical edge?

- Q: How do you close the wallpaper?

- It doesn't have to be sealed. If you want to seal it, anything is OK and the box is ok.Of course, the nail is the best. Glue and nails are usually used.Wallpaper construction process and construction technology1. grassroots treatmentPaste before, should be on the surface of the base substrate or dirt, clean the dust, efflorescence parts with dilute acetic acid and cleaning nine percent. The base may not have flying thorn, pitting, sand and cracks, yin and yang angle should be straight. The surface is smooth and sticky.After the grassroots cleaning, in the grass-roots to play putty, dry sandpaper polished.2. brush primerPaint with an environmental varnish, solution, etc on the base surface.3. part elastic lineFirst of all, the interior is facing indoor, dead angle, according to wallpaper width row, Yang Kok should be wrapped angle, overcast corner to overlap, and according to the plan to play the vertical line, and number marked, as a sticky line.4. cut paperAccording to the wall frame size, cut the paper according to the requirements on patterned wallpaper pattern, the corresponding number two, she set aside 30---50MM volume cutting, flat.5. brush adhesiveThe table will wipe the back cut wallpaper to flat, with a flat brush or roller coating, and press the upper 1/3, lower 2/3, rubber face rubber surface after folded into a cylinder by post. (ten, wall felt back glue, in order to avoid the pollution of positive. Glue only to the wall.).6, stickyThe brush glue after the wallpaper launched folding the top part of posts on the wall, along the vertical datum line (horizontal) post wall (ceiling), with a plastic scraper or brush to scrape out, and she bubble adhesive, with a clean towel to wipe seam wallpaper, wallpaper knife to cut the number she part.

- Q: How should the reinforcing rib of the reinforcing bar of the cap be arranged?

- Then you have to see the design requirements. If not, refer to the 85-91 page of the 11G101-3 atlas, depending on the type of the cap

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; South Asia. |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 500-700 People |

| Language Spoken: | Chinese; English |

| b) Factory Information | |

| Factory Size: | Above 800,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | |

| Product Price Range | Middle |

Send your message to us

Automatic Straight Edge Banding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000pcs/Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords