China Aluminum Oxide Sandpaper Sheets for Prepainting Coated Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

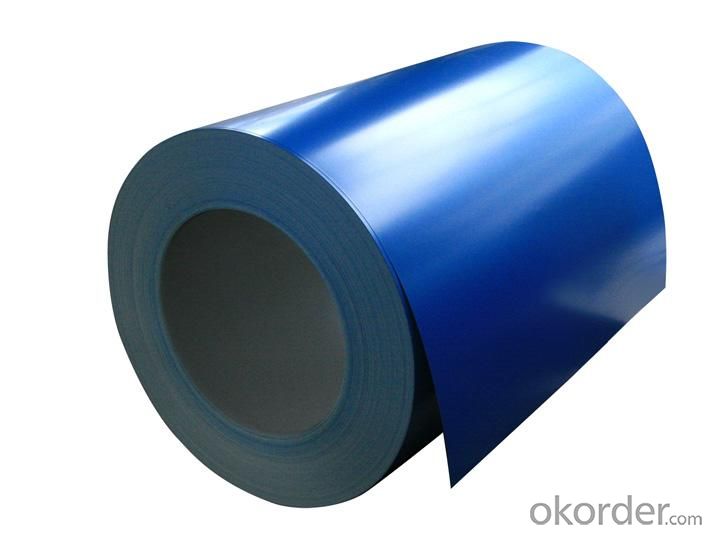

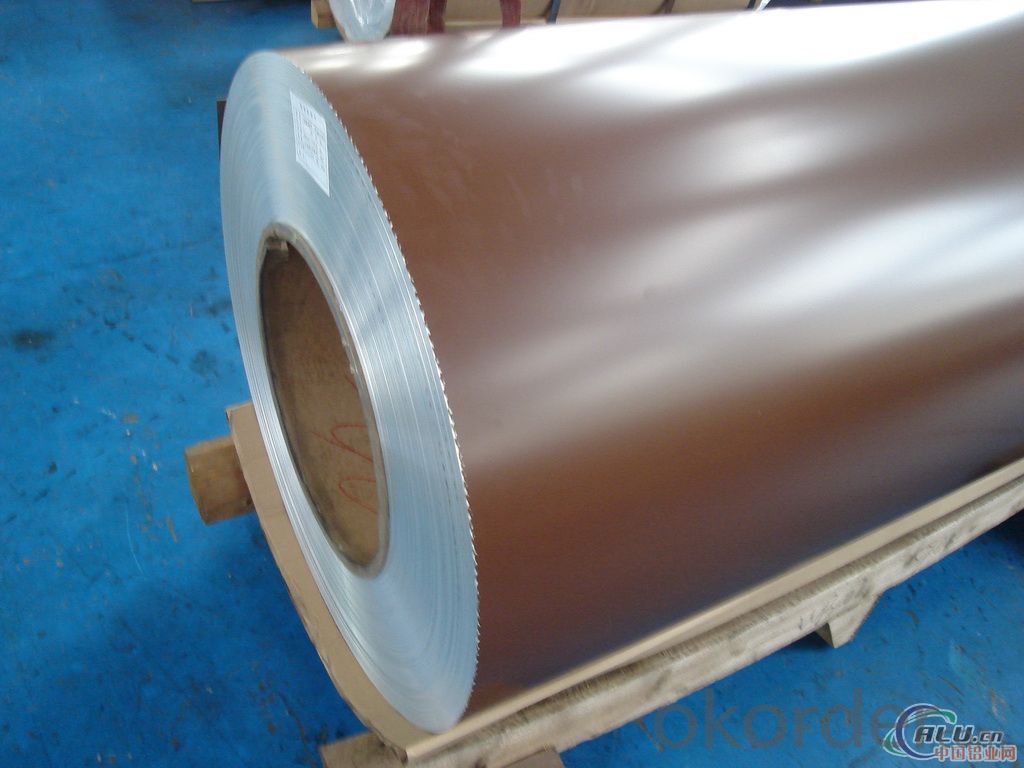

1.Structure of Aluminium Coils for Prepainting Coated Coils

Aluminium Coils for Prepainting Coated Coils is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Prepainting Coated Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To prevent galvanic corrosion when using aluminum sheets with saltwater, several measures can be taken. Firstly, applying a protective coating or paint to the aluminum surface creates a barrier between the metal and the saltwater, reducing the chances of corrosion. Secondly, using sacrificial anodes made of a more reactive metal, such as zinc, can divert the electrolytic current away from the aluminum sheets, preventing corrosion. Additionally, ensuring proper insulation and avoiding contact with dissimilar metals can also help minimize the risk of galvanic corrosion in saltwater environments.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Yes, aluminum sheets can be used for manufacturing medical equipment. Aluminum is a versatile and widely used material in various industries, including healthcare. It has several properties that make it suitable for medical equipment manufacturing. Firstly, aluminum is lightweight yet durable, which is beneficial for portable medical devices. It allows for easier handling and transportation of equipment, especially for healthcare professionals who may need to move them frequently. Secondly, aluminum has excellent corrosion resistance, making it suitable for medical applications where cleanliness and hygiene are crucial. It can withstand disinfection processes without deteriorating, ensuring the longevity of the equipment. Additionally, aluminum can be easily sterilized, which is essential for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without any adverse effects on its structural integrity. Moreover, aluminum is an excellent conductor of heat and electricity. This property is advantageous for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is a non-toxic material, making it safe for medical use. It does not leach harmful substances, ensuring that it does not pose any health risks to patients or healthcare professionals. In conclusion, aluminum sheets can indeed be used for manufacturing medical equipment due to their lightweight, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, and non-toxic nature. These properties make aluminum a suitable choice for various medical applications, contributing to the advancement of healthcare technology.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- I've been chased with an aluminum bat, but haven't ever been hit with either. I would say that the wooden bat would hurt more, because that's solid wood. An aluminum bat is hollow. But then yet, I've red articles where aluminum bats perform better for some kind of scientific reason that I didn't quite understand. So if an aluminum bat performs better on a baseball, it would be safe to assume that perhaps it would hurt more to be hit with an aluminum one. But either way, it's safe to say... I'd rather not be hit with either!

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- I say go with wood. Aluminum bats just are not as safe. The ball comes off the bat with so much more speed, the reaction time for an infielder, pitcher, or someone in the stands is reduced and people don't always have time to react to the ball.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- The corrosion resistance of 101 aluminum sheets in saltwater environments is generally considered to be quite good. Aluminum is inherently resistant to corrosion, and when exposed to saltwater, it forms a protective oxide layer on its surface that further enhances its resistance to corrosion. This oxide layer acts as a barrier, preventing the saltwater from coming into direct contact with the underlying metal and thus slowing down the corrosion process. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time. Regular maintenance and protective coatings can help to further enhance the corrosion resistance of 101 aluminum sheets in saltwater environments.

- Q: What are the potential health hazards related to working with aluminum sheets?

- <p>Working with aluminum sheets generally has low health risks. However, inhalation of aluminum dust can cause respiratory issues, such as coughing and shortness of breath. Prolonged exposure may lead to a condition known as metal fume fever. Additionally, aluminum can cause skin irritation in some individuals. It's important to use proper ventilation and personal protective equipment, such as masks and gloves, to minimize these risks.</p>

- Q: Are the aluminum sheets suitable for decorative purposes?

- Indeed, decorative purposes can be served by aluminum sheets. Aluminum, a material known for its versatility, can be effortlessly molded, trimmed, and maneuvered to produce a myriad of decorative components. Its lightweight nature, durability, and resistance to corrosion contribute to its widespread adoption for both indoor and outdoor uses. The availability of aluminum sheets in a vast array of finishes, colors, and patterns further amplifies the scope for limitless design options. Whether it is for embellishing architectural accents, crafting signage, manufacturing furniture, or producing artwork, aluminum sheets possess the potential to elevate the visual allure of any given area.

- Q: What is the reflectivity of aluminum sheets?

- The reflectivity of aluminum sheets is quite high, typically ranging from 80% to 90%. This high reflectivity is due to the smooth surface and the unique properties of aluminum, which allow it to efficiently reflect light and other electromagnetic waves. This makes aluminum sheets commonly used in applications where high reflectivity is desired, such as in the construction of reflective surfaces, solar panels, and mirrors. Additionally, the reflectivity of aluminum can be further enhanced by applying a reflective coating or polishing the surface.

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive. Aluminum is a metal and has a high electrical conductivity. This means that electricity can easily flow through aluminum sheets, allowing them to be used in various applications where conductivity is required, such as in electrical wiring, power transmission lines, and electronic devices.

- Q: What are the safety precautions when working with aluminum sheet?

- When working with aluminum sheet, it is important to take certain safety precautions. These include wearing personal protective equipment such as gloves, safety glasses, and a dust mask to protect against potential hazards. It is also advisable to work in a well-ventilated area to avoid inhaling any fumes or dust particles. Additionally, using appropriate tools and machinery specifically designed for handling aluminum sheets is essential to prevent accidents or injuries. Finally, proper handling and storage of aluminum sheets, ensuring they are stacked securely and avoiding any sharp edges, can help minimize the risk of accidents or damage.

Send your message to us

China Aluminum Oxide Sandpaper Sheets for Prepainting Coated Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords