Cheapest Aluminum Prepainted Coil for Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

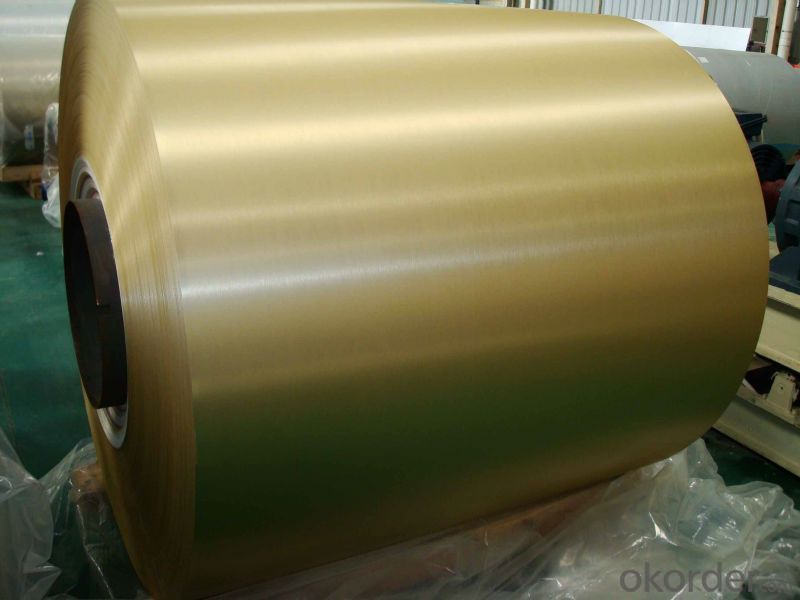

Structure of Aluminium Prepainted in Coil Form for Roofing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted in Coil Form for Roofing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Prepainted in Coil Form for Roofing:

Aluminium Prepainted in Coil Form for Roofing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainted in Coil Form for Roofing:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the various color and pattern options for aluminum sheets?

- <p>Aluminum sheets are available in a wide range of colors and patterns to suit various applications and aesthetic preferences. Colors can include silver, white, black, bronze, and many other shades. Patterns can range from simple matte or gloss finishes to more complex textures like wood grain, stone, and brushed metal effects. Some aluminum sheets also feature anodized finishes for enhanced durability and color vibrancy. Custom colors and patterns can be created through specialized coating processes, allowing for a high level of personalization in design and construction projects.</p>

- Q: What is the typical machinability of aluminum sheets?

- The machinability of aluminum sheets is generally considered to be excellent. Aluminum is known for its relatively low density and softness, which makes it easier to machine compared to other metals. It has good thermal conductivity, allowing for efficient removal of heat generated during machining, and it also has a low melting point, reducing the risk of overheating. Additionally, aluminum has good chip formation characteristics, resulting in easy chip evacuation and reduced tool wear. However, the machinability of aluminum can vary depending on factors such as alloy composition, tempering, and surface finish. Overall, aluminum sheets are widely regarded as being highly machinable.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: Can aluminum sheets be used for heat shields in appliances?

- Appliances can utilize aluminum sheets as heat shields. Aluminum, being a lightweight and highly conductive material, effectively disperses heat. Its ability to withstand high temperatures is due to its high melting point, making it an ideal material for heat shield purposes. Furthermore, aluminum's corrosion resistance guarantees the durability and longevity of the heat shield. Its flexibility enables easy installation and shaping to accommodate different appliance designs. Aluminum sheets find widespread use in appliances like ovens, grills, and heating units as a safeguard against excessive heat, preventing potential damage to surrounding areas.

- Q: The radius of an atom of aluminum is 143pm and there are 10^12 in a meter. The aluminum is a 3x3cm square. The density is 2.70 g/cm^3. I found the mass to be 0.03g. I found the volume to be 0.09cm^3

- Good quality standard aluminum foil such as Reynolds brand is 0.007 inches thick. If aluminum atoms are indeed 143 picometers in radius then the foil would be 2,486,713 atoms thick. Of course, the thickness is not controlled to a tolerance of one atom. (Cheaper brands are about 0.0060 to 0.0065 inches thick.) The ionic radius of aluminum is commonly accepted to be 72 pm, and as of 2008 a covalent radius of 121 pm. . .

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. They are lightweight, durable, and resistant to corrosion, making them an excellent choice for roofing materials. Additionally, aluminum sheets have good thermal properties, reflecting sunlight and helping to keep the building cool.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: 10mm how much is the aluminum sheet?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liaoning Wang Zhong Nanshan aluminum do this thickness.

- Q: Can aluminum sheet be used for electronic components?

- Yes, aluminum sheet can be used for electronic components. Aluminum is a versatile material that offers several advantages for electronic applications. It is lightweight, has excellent thermal conductivity, and is resistant to corrosion. These properties make it suitable for a wide range of electronic components, such as heat sinks, enclosures, connectors, and printed circuit boards (PCBs). Aluminum sheets can be easily machined, formed, and welded, allowing for efficient manufacturing processes. Additionally, aluminum is a cost-effective material compared to alternatives like copper or steel. However, it is important to note that aluminum is not suitable for all electronic components, especially those that require high electrical conductivity or magnetic shielding.

Send your message to us

Cheapest Aluminum Prepainted Coil for Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords