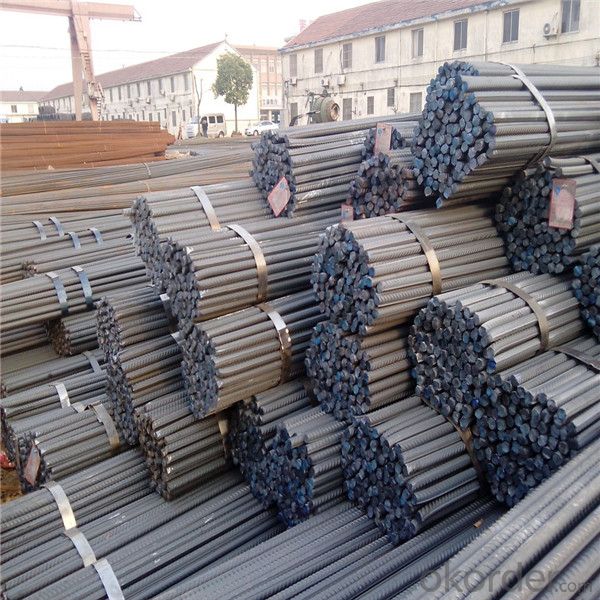

Steel rebar manufacturer supply deformed steel rebar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar has ridges that bind it mechanically to the concrete with friction, it can still be pulled out of the concrete

under high stresses, an occurrence that often precedes a larger-scale collapse of the structure. To prevent such a

failure, rebar is either deeply embedded into adjacent structural members, or bent and hooked at the ends to lock it

around the concrete and other rebars. This first approach increases the friction locking the bar into place while the

second makes use of the high compressive strength of concrete

Rebar is common steel reinforcing bar, an important component of reinforced concrete and reinforced masonry structures.

It is usually formed from mild steel, and is given ridges for better frictional adhesion to the concrete

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How are steel rebars used in water treatment plants?

- Steel rebars are commonly used in water treatment plants to reinforce the concrete structures that are essential for the plant's operations. These rebars provide strength and durability to the concrete, ensuring that the structures can withstand the harsh conditions and loads associated with water treatment processes.

- Q: How do steel rebars affect the overall sustainability of a structure?

- The overall sustainability of a structure is significantly influenced by steel rebars. To begin with, the utilization of steel rebars adds to the building's strength and durability, ensuring its longevity and decreasing the need for frequent repairs or replacements. As a result, the consumption of raw materials and energy required for construction is reduced, making the structure more sustainable. Moreover, steel rebars aid in improving the structural integrity of a building, rendering it more resilient to natural disasters like earthquakes and hurricanes. By enhancing the safety and resilience of the structure, steel rebars minimize the potential for damage and loss, thereby reducing the environmental impact associated with reconstruction and waste generation. Additionally, at the end of a building's life cycle, steel rebars can be recycled. Steel is highly recyclable, and the reuse of steel rebars significantly decreases the demand for virgin steel production and the related carbon emissions. Steel recycling also conserves natural resources and reduces landfill waste, making it a more sustainable alternative to using other materials. Furthermore, the incorporation of steel rebars in structures allows for greater design flexibility and adaptability. This implies that buildings can be easily modified or repurposed, reducing the necessity for demolition and reconstruction. The ability to repurpose existing structures reduces waste and energy consumption, contributing to the overall sustainability of the built environment. In conclusion, steel rebars have a positive impact on the overall sustainability of a structure through their durability, strength, and recyclability. By enhancing the longevity, safety, and adaptability of a building, steel rebars decrease the environmental impact associated with construction, maintenance, and demolition.

- Q: How do steel rebars enhance the structural integrity of a building?

- In several ways, the structural integrity of a building is enhanced by steel rebars. Firstly, they reinforce and support concrete structures, including beams, columns, and slabs, preventing cracking or collapsing under heavy loads or external forces. The high tensile strength of steel rebars enables them to bear tensile stresses that concrete alone cannot handle, guaranteeing the building's stability and durability. Furthermore, steel rebars aid in evenly distributing and transferring loads throughout the structure, reducing concentrated stress. By reinforcing critical areas prone to tension, like corners, joints, and openings, rebars prevent cracks and ensure overall stability. Steel rebars also play a vital role in improving the structure's resistance to natural disasters like earthquakes and hurricanes. The flexibility and ductility of steel allow it to absorb and dissipate energy during seismic events or high winds, minimizing the risk of structural failure. This increased resilience ensures occupant safety and protects the building from severe damage. Additionally, steel rebars offer long-term durability by shielding the structure against corrosion. Unlike other construction materials, steel is highly resistant to degradation caused by environmental factors like moisture, chemicals, and temperature fluctuations. Corrosion-resistant rebars or protective coatings can significantly extend the building's lifespan. In conclusion, steel rebars are crucial components for reinforcing concrete structures, strengthening their integrity, stability, and resilience. By providing additional support and resistance to various stresses and loads, they contribute to the overall structural integrity of a building, guaranteeing its safety, longevity, and ability to withstand adverse conditions.

- Q: Can steel rebars be used in tunnel lining construction?

- Tunnel lining construction readily employs steel rebars, given their exceptional tensile strength and durability. These rebars are extensively utilized as they furnish structural reinforcement to the concrete lining, assuring its stability and long-term performance. Typically, the rebars are embedded within the concrete lining, creating a robust composite structure that effectively withstands the various loads and pressures encountered in tunnel environments. Moreover, steel rebars can be easily molded and flexed to conform to the tunnel's shape, facilitating efficient and precise construction. Overall, steel rebars represent an indispensable element in tunnel lining construction, guaranteeing the essential strength and structural integrity that safeguard the safety and longevity of the tunnels.

- Q: What are the environmental benefits of using steel rebars?

- Using steel rebars in construction projects has several environmental benefits. Firstly, steel rebars are highly durable and long-lasting, which means they have a significantly longer lifespan compared to other materials. This reduces the need for frequent replacements and minimizes the amount of waste generated. Additionally, steel rebars are 100% recyclable, allowing them to be repurposed in new construction projects, reducing the demand for new materials and conserving natural resources. Furthermore, steel production emits fewer greenhouse gases compared to other materials like concrete, contributing to reduced carbon emissions and mitigating climate change. Overall, the use of steel rebars supports a more sustainable and eco-friendly approach to construction.

- Q: What are the different types of steel rebars used in high-rise buildings?

- The different types of steel rebars commonly used in high-rise buildings include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. These rebars have varying properties and are chosen based on factors like strength, corrosion resistance, and durability to ensure structural integrity and safety in the building's construction.

- Q: How are steel rebars anchored into existing concrete?

- Steel rebars are commonly used to reinforce existing concrete structures. The process of anchoring steel rebars into existing concrete involves several steps. First, the concrete surface needs to be prepared. This typically involves cleaning the area where the rebar will be anchored to remove any dirt, debris, or loose concrete. The surface may also need to be roughened to provide better adhesion. Once the surface is prepared, a bonding agent such as epoxy or a cementitious grout is applied. This bonding agent helps to create a strong bond between the rebar and the concrete. Next, the steel rebar is positioned and inserted into the prepared area. The length of the rebar that is inserted into the concrete depends on the required anchorage depth and the design specifications. The rebar should be positioned at the correct depth and aligned according to the structural requirements. To ensure proper anchorage, the rebar is often bent or hooked at the end. This helps to prevent the rebar from pulling out of the concrete under tension or other external forces. Finally, the bonding agent is left to cure according to the manufacturer's instructions. This allows the bonding agent to harden and form a strong bond between the rebar and the concrete. It is important to note that the exact method of anchoring steel rebars into existing concrete may vary depending on the specific application and design requirements. In some cases, additional reinforcement methods such as mechanical anchors or post-installed anchors may be used to enhance the anchorage strength. Professional expertise and adherence to engineering guidelines are crucial to ensure the proper and safe anchoring of steel rebars into existing concrete structures.

- Q: Are there any limitations on the maximum length of steel rebars used in construction?

- Yes, there are limitations on the maximum length of steel rebars used in construction. The maximum length of steel rebars can vary depending on various factors such as the structural design, construction codes, and transportation limitations. In general, the length of steel rebars is limited by practical considerations such as handling, transportation, and installation. Very long rebars can be difficult to transport and maneuver on construction sites. Additionally, excessively long rebars may be more prone to bending or sagging, which can affect their structural integrity. Therefore, construction industry standards and codes typically provide guidelines or restrictions on the maximum length of steel rebars to ensure their safe and efficient use in construction projects. It is important for architects, engineers, and contractors to adhere to these limitations to ensure the structural stability and safety of the building.

- Q: In the concrete floor, how big can the steel bar be replaced by the big screw steel? How to convert?

- The strength of the reinforcement to be replaced must be greater than or equal to the original strength of the reinforcement. The tensile strength of the original reinforcement, the square of the diameter * the tensile design strength / the diameter of the reinforcement to be replaced by the square *, the tensile design strength.

- Q: How do steel rebars help in reducing construction time?

- Steel rebars contribute to the reduction of construction time in several ways. Firstly, they enhance the strength and durability of concrete structures, enabling builders to employ quicker construction techniques. This obviates the necessity for slower and more time-consuming methods as the rebars provide sufficient support for the structure's weight. Secondly, the reinforcement of concrete with steel rebars enhances the overall structural integrity of the building. Consequently, builders can employ thinner concrete sections without compromising the structure's strength. These thinner sections require less material and can be poured and cured more rapidly and easily, thus saving construction time. Thirdly, the installation of steel rebars is a speedy process due to their easy handling and installation characteristics. They can be conveniently cut and bent to fit the desired shape and size, facilitating efficient installation. Consequently, the requirement for complicated and time-consuming formwork is eliminated, resulting in a reduction in construction time. Fourthly, steel rebars offer design and construction flexibility, enabling the utilization of innovative and efficient building techniques. They can be utilized in a variety of applications, including beams, columns, and slabs, granting architects and engineers the freedom to design structures that can be rapidly and efficiently constructed. Lastly, steel rebars provide additional resistance to natural disasters such as seismic activity and extreme weather conditions. By reinforcing concrete with rebars, structures become more resilient, reducing the risk of damage and expediting the construction process. This is particularly crucial in areas that are prone to earthquakes or adverse weather conditions. In conclusion, steel rebars play a pivotal role in reducing construction time by providing strength, durability, flexibility, ease of installation, and the ability to reinforce concrete structures. These qualities facilitate faster construction methods and efficient use of materials.

Send your message to us

Steel rebar manufacturer supply deformed steel rebar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords