Ceramic Foam Filter for Foundry Stainless Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

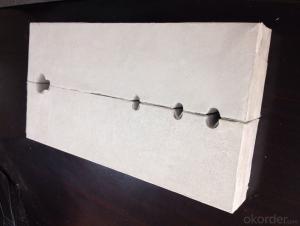

General Information of Ceramic Foam Filters

Zirconia ceramic foam filters are mainly used to filter the steel and steel alloys required the higher temperature of 1780℃.It is strongly recommended to be used for high quality grades of steel alloys.

Features of Ceramic Foam Filters

Improving the steel casting quality

Excellent thermal shock resistance

High porosity with good strength

High efficiency to filter the steel dross

Tailored sizes as customer’s requirement

Image of Ceramic Foam Filters

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q: What's the difference between white carbon and carbon black? Can they be replaced?

- Carbon black is the floorboard of white powder X- ray of amorphous silica and silicate products, mainly refers to the precipitated silica, fumed silica, ultrafine silica gel and gel, including powder synthetic aluminium silicate and calcium silicate. Silica is a porous material, its composition by SiO2 nH2O, where nH2O is there the surface hydroxyl form. Soluble in caustic and hydrofluoric acid, insoluble in water, solvent and acid (except hydrofluoric acid). High temperature resistant, non flammable, tasteless, odorless, has the very good electric insulation.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Mineral wool board ceiling is different than the calcium silicate board ceiling. Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board. The fire performance of third mineral wool board no calcium silicate board, mineral wool board fourth dampeasily yellow, moisture absorption is not good.

- Q: Cement is not silicate products

- Usually refers to silicate products with lime (calcium containing materials) and sand, fly ash, slag (siliceous materials), then add a small amount of gypsum, the steam steam curing or steam curing, building products quickly generate Tobey mullite, calcium silicate, hydrated calcium aluminate sulfate and hydrated calcium aluminate such as cementitious materials and production. Such as: autoclaved fly ash (sand), autoclaved aerated concrete, autoclaved fly ash brick, autoclaved sand lime bricks.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Low carbon steel nail insulation (aka: insulation pins) material: low carbon steel wire for power plants or stainless steel wire products: insulation nail. Hook nail is a power plant by mechanical processing of special insulation nail models: nail diameter: 3 mm with 3.5mm with 4 mm with 5 mm with 6 mm etc.

- Q: How to make building glue?

- Universal type building adhesive and preparation method thereof, which is characterized in that the main components of the building glue: TDI, polyether, polyester, multiple resin, natural plant resin, polystyrene thin ester, solvent oil and ultraviolet resistant, anti-aging agent, component ratio (by weight) of:TDI2%--7%, 3%--8%, polyester polyether 1%--6%, multi resin 6%--15%, natural plant resin 6%--15%, polyphenyl ester 14%--25%, savanna solvent oil 10%--20%, anti UV, anti ageing agent 1%--4%.

- Q: What is dew point of thermal insulation material?

- Insulation materials, insulation for industrial equipment and piping, thermal insulation measures and material aerogels were first applied to the space suit thermal insulation linings developed by nasa. With low thermal conductivity, small density, high flexibility, fire, waterproof and other characteristics. Its temperature coefficient of thermal conductivity 0.018W/ (K = m) and absolute waterproof, insulation performance is 3~8 times of traditional materials.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Composite silicate insulation material has the characteristics of strong plasticity, low thermal conductivity, high temperature resistance, small drying shrinkage and so on. The main types are magnesium silicate, silicon magnesium aluminum and rare earth composite thermal insulation materials. But in recent years as a leader in thermal insulation material of Sepiolite Composite silicate insulation material, because of its good insulation performance and the application effect, has attracted great attention in the construction industry, has shown strong market competitiveness and broad market prospect.

Send your message to us

Ceramic Foam Filter for Foundry Stainless Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords