Lightweight Micro Insulation Board High/low Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

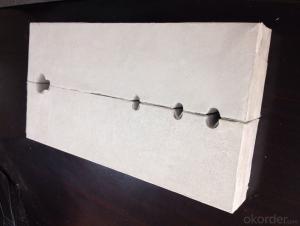

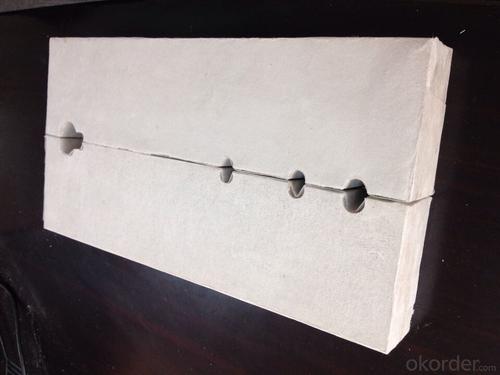

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the maximum temperature at which the glass is cured?

- There is no definite melting point. Ordinary glass is a substance which is made up of soda ash, calcium silicate and silicon dioxide, and Shi Yinghe feldspar is the main raw material.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Calcium silicate board called gypsum composite board, is a kind of porous material, good sound and heat insulation, in indoor air moist circumstance can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. It is super fire gypsum material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: Eterpan and yinte in what is the difference?

- Eterpan:Eterpan, is a kind of fiber reinforced silicate plate (fiber cement board), the main raw material is cement, plant fiber and minerals, the flow of high temperature steam pressure and slurry method, mainly used as building materials.Eterpan is a kind of high strength, durability and other advantages of fiber silicate sheet, with various thickness and density, 100% does not contain asbestos and other harmful substances. For non combustible A1 grade products.The utility model has the advantages of fire prevention, moisture proof, waterproof, sound insulation effect, environmental protection, quick installation, long service life, etc.. Often used for wall panels, bathroom partitions, outdoor roofing, roofing, exterior insulation panels, interior decoration, ceilings, etc.; alsoInstead of gypsum board, used as base material in decoration.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- The current power plant thermal insulation is mainly carried out by use of various types of insulation materials, thermal insulation materials commonly used include calcium silicate products, pipes, rock and aluminum silicate fiber products, due to their different properties are applicable to different environments. The equipment with temperature at 300-600 DEG C often adopts aluminium silicate products and calcium silicate products to compound heat preservation. While the temperature is less than 300 degrees, the mineral wool products are usually used for thermal insulation.

- Q: What's the difference between white cement and ordinary cement?

- The typical feature of white cement is high whiteness, with bright color, generally used for a variety of architectural decoration materials, painting, sculpture, a typical floor, terrazzo, white cement can be used to produce white and colored concrete, is the largest cement production decoration.

- Q: What is the main role of fly ash added in concrete products?

- The later strength of concrete can be improved by adding fly ashThe experimental data show that when the concrete is mixed with fly ash, the early strength (28 days ago) decreases with the increase of fly ash content, while the latter strength increases gradually. Fly ash has three effects on the strength of concrete: reducing water consumption, increasing cement content and increasing strength through long-term volcanic ash reactions.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- The market is generally understood, but in fact, Eterpan belongs to Guangzhou eternit limited production of the 100 year history of eternit brand board, because the cement product is Belgium hetet group invention.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Foam heat insulation material mainly includes two categories, polymer foam type insulation material and foam asbestos insulation material. Polymer foam thermal insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, etc., and it is in the period of popularization and application.

Send your message to us

Lightweight Micro Insulation Board High/low Density

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords