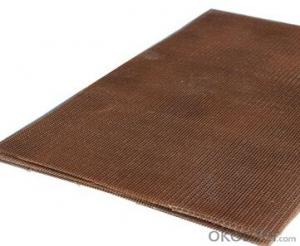

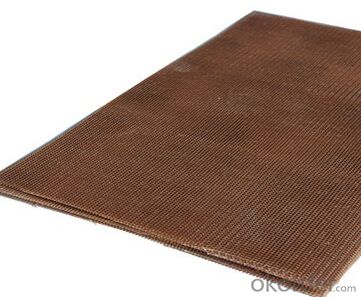

Ceramic Filter Plate Netlike Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Iron-water filtrationAluminum-water filtration

Steel-water filtration

Copper-water filtration

Cap-filter net

During the manufacture of casting, due to some reasons, when cast steel, iron, aluminum and other metal castings, it is easily to meet the quality problems, such as arising slag hole, sand hole, gas hole, etc. Thereby, it has high technical value and economic value to remove the non-metal material from the metal material, so that promoting the rate of casting finished products, and casting quality either.

The filtering net for foundry produced by our company are manufactured with resistant-high-temperature fiber, further more, they are produced by special technique and following-process, so with special technology and stable quality, the products of our company have been systematically.

Compared to other kinds of net for casting filter, the resistant-high-temperature fiberglass netlike for foundry is with lower quotation, higher ability of filtering residue and lower gas arising, thus it is easy to use and could keep the element of metal steadily; what is more, these products have good performance on high temperature resistant, flame resistant, good chemical stability and intensity of steel. Thereby, this kind of filtering netlike cloth is the favorable filtering material for various metal-water. It could be used on chemical liquid filtering and high-temperature gas filtering either.

Resistant-high-temperature fiberglass netlike for foundry are widely used to filter and purge all kinds of metal-water, by using our products, it could get the next aims:

Effectively get rid of the blister, oxide with dust and such kind of impurity in metal-water, by this to erase the residue hole, sand hole, gas hole of the casting ultimately, so that improve the inside and blanket quality of the casting, the finished-products either.

Improve the mechanical ability of casting: increasing the stiffness of casting, further more, the blanket becomes more homogeneous and strength of resisting bend has improved.

Change the carbon form of casting, in order to decrease the size of carbon, reduce the thickness and make the figure flexuous slightly.

Alter the mechanical manufacture capability of casting, improve the efficiency of processing.

Main products: Aluminum-water filtration, Steel-water filtration, Iron-water filtration, Copper-water filtration, Cap-filter net, etc. the main mesh size are: 1.0x1.0, 1.2x1.2, 1.5x1.5, 2.0x2.0, 2.5x2.5, etc. We could make products of special gauge to satisfy customers’ order, either.

Welcome your enquiry at any time, We are pleased to supply you qualified product with professional service.

- Q: How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: What is the working pressure of the ceramic filter?

- The backwash pressure is the size of the backwash of the ceramic filter during recoil stage, and the recoil pressure is generally less than 0.12MPa. The greater the pressure, the better the recoil effect, the better the service life and the suction effect of the ceramic filter plate, and the worse the service life and the suction effect of the ceramic filter board. The backwash pressure of the ceramic filter shall be no less than 0.07MPa.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- The backwashing system of ceramic filter is usually made up of water inlet, water inlet, pressure gauge, water filter and filtered water pressure gauge, and then connected to the inside of ceramic filter. Such as the discovery of ceramic filter recoil pressure became smaller or even no recoil pressure, you can carefully observe the surface of the ceramic filter plate is wet or ceramic filter plate wear without water injection at the discharge point, investigation and the reasons for the following aspects:Is the water inlet pressure or normal?How about the sealing performance of the water filter? Does the filter element need to be replaced?Is the recoil system piping (metal pipe, ceramic filter plate, connecting pipe, etc.) broken, leaking or dripping?Is the distributor valve properly installed and is it worn?Are there any cracks in the ceramic filter plate?Is the pressure gauge broken?The most likely reason is 1, 2, two, the best water should not be too dirty, filter should be replaced regularly. I hope the answer can help you.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter automatic control system: control system through the metering pump will be concentrated nitric acid automatic mixing ceramic filter plate into nitrate after proportioning through the pipeline, so that it can be dissolved, dredge the blockage in the most microporous ceramic filter plate. This is the ceramic filter plate pickling, pickling, acid dosage should be sufficient as little pickling effect.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: What are the reasons for the program alarm of ceramic filter?

- If you say "lean" is the ceramic filter suction when the ceramic filter plate into a cake of thin, high water content, is the ceramic filter for their own reasons, can from the following aspects: the investigation considering this phenomenon is always so recently or just happened, if you have been so, probably because your selection is not suitable for pulp the ceramic filter (such as mud content, fine grain size, ceramic filter plate selection such as inconsistent or unqualified ceramic filter). If this anomaly has occurred recently, it is possible to change the ore condition, and the operation parameters of ceramic filters or the cleaning are not up to standard. You can check the vacuum system (vacuum generally ranges from -0.09 to -0.075MPa), backwashing system (generally refers to the filtered water recoil 0.07 ~ 0.12MPa), acid (HNO3 system standards), ultrasonic system is normal.

Send your message to us

Ceramic Filter Plate Netlike Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches