Cementitious Capillary Crystalline Waterprofing (CCCW) Coating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cementitious Capillary Crystalline Waterprofing (CCCW) Coating

PRODUCT DESCRIPTION

Cementitious Capillary Crystalline waterproofing coating comprises ordinary Portland cement, quartz sand as basic material

and compounds active chemical substances to form rigid waterproofing coating with permeating and crystallization properties.

It is specially applied to the underground concrete structure and concrete structure contacting with water for the crack

resistance and leakage proof. Its waterproofing principle is that the active chemical substances contained in CCCW coating

permeates into the concrete by water carrier and forms water-fast crystalline to block concrete capillary, integrate with

concrete and reach the purpose of water and leakage proof. The free calcium oxide, moisture and the active chemical

substances contained in CCCW coating is the precondition that cementitious capillary crystalline waterproofing coating forms

crystalline and improves.

PRODUCT FEATURES

No poison, no smell, no pollution, good to environment protection

Mainly consisted of ordinary Portland cement and compatible with concrete substrate

High self curing capability for cracks (size of cracks ≤ 0.3mm)

Applied to wet substrate and shorten construction period

Easy installation, convenient operation and save manpower cost

Convenient transportation, storage and save cost as it exists in powder

The waterproofing film able to bear certain external force

The permanent waterproofing measures without material aging

PERFORMANCE INDEX

Executive standard: National Standard GB/T 18445-2012

TECHNICAL DATA

S/N | Items | Units | Index | |

1 | Appearance | No caking,even | ||

2 | Water content | % | 1.5 | |

3 | Fineness(residue on sieve 0.63mm) | % | 5 | |

4 | Application propety | Stiming after adding water | Scrap out without resistance | |

20minutes | Scrap out without resistance | |||

5 | Demolishing resistance | Mpa,28d | ≥2.8 | |

6 | Pressure resistance | Mpa,28d | ≥15.0 | |

7 | Adhesion to wet substrate | Mpa,28d | ≥1.0 | |

WHERE TO USE

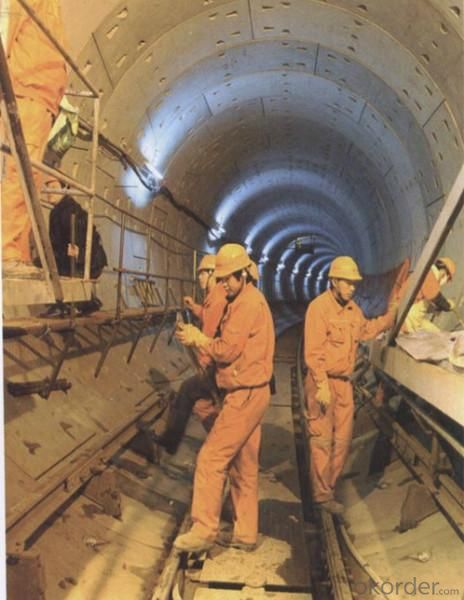

Applicable to waterproofing projects and anti-permeation projects of concrete like underground works, metros, tunnels, waste

water treatment ponds, running water pools, drainage gutters, canals etc.

CONSTRUCTION TECHNIQUES

a) Scraper applied method

1) Mixture of grout:

Mixture of grout is critical to assure the quality of waterproofing construction. Add the clean water and stir the grout. It shall be

used up in thirty minutes after completion of stirring 3kg grout in case of wasting material. The grout can’t be used any more if

it is cured. Strictly control water cement ratio. Mix 4 shares compound with 1 share water and stir them pasty( ratio could be

adjusted as per local temperature).The grout shall be no dry part and sufficiently stirred.

2) Requirement for treatment of substrate:

Start the waterproofing commencement at proper time after completion of new structure construction. The original

waterproofing layer of old structure shall be removed ant coated with the new coating. The surface of substrates shall be dust

free, no greasy dirt, no concave or protrusion. They shall be rectified if there is any defect on the substrates. Furthermore, the

substrates shall be wetted prior to application of coating.

3) Precaution of construction:

Evenly scrape the mixed grout to the substrates. When commencing waterproofing construction to the surface facing water,

the amount of grout shall be increased to try the best to improve the permeable resistance of waterproofing layer. Be aware of

treatment of the pitted surface. Stop the leakage when backing the water.

Normal amount: in rat of 1.0-1,2kg/m2

Thickness of coating: 1-1.2mm

Construction requirement: one-time application. Brush or spray the waterproofing coating with water before initial setting. Keep

scraping the grout while keeping wetting it. This is very critical. Keep spraying the coating with water one or two days if it is

exposed to sunlight.

b) Brush applied method

1) Mixture of grout:

Please refer the above scraper applied method. Stir three shares compounds with one share water to pasty. The mixed grout

shall be scraped in certain thickness.

2) Please refer to the above scraper applied method for requirement for treatment of substrate and precaution of construction

Normal amount: ≥ rat of 1.0kg/m2

Thickness of coating: 0.8-1.0mm

Construction requirement: two or above two times application. Keep surface of substrates clean. But do less wet treatment to

surface of substrates. Keep wetting the coating with water one or two days if it is exposed to sunlight.

c) Powder applied method

1) Spread the compounds to the surface of concrete in required amount prior to incomplete coagulation and scrape and press

it down. Inspect the coating during the final setting time. Rectify it if any defects are found. Spray it with water a day if exposed to the sunlight. Evenly spread the compound ( Prepare construction method

statement as per the actual projects)

2) Normal amount: ≥ rat of 1.0kg/m2

Thickness of coating: 0.8-1.0mm

Packaging, transport and storage

1. The powder product is packed with 25 ± 0.25kg laminating woven bag. Packaging specifications should meet the user requirements.

2. Powder product is easy to soluble in water, liquid dilution will affect the effective concentration of the product, transport and storage should be noted that the anti-leaching, avoid moisture, direct sunlight, kept under seal and away from open flame at the room temperature or during the transport.

3. In the case of good storage conditions, valid period is three years. If it is more than 3 years, rechecking is needed for using continually.

FAQ

1.Q: What is MOQ?

A: Our MOQ is 1 TON.

2.Q: Could you offer free sample?

A: We can provide free samples to you for quality testing.

3.Q: What about your packing?

A: For liquid: Flexitank, or IBC tank 1000L

For powder:Woven fabric bag with plastic film liner( 25kg or 1000kg)

Clients’ packing is workable.

4.Q: How about your productive capacity?

A: 150000 tons/Year.

5.Q: What is your delivery time?

A: Within 7 days after received deposit or L/C at sight.

Send your message to us

Cementitious Capillary Crystalline Waterprofing (CCCW) Coating

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords