CE Certificated Real Wood Short Cycle Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CE certification real wood short cycle press machine

Products detail

Real wood short cycle press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Real wood short cycle press machine is availale according to your requirements!

Features

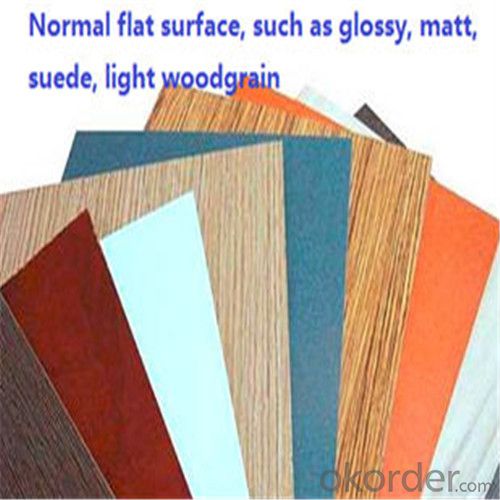

Real wood short cycle press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Real wood short cycle press machine are for)

Real wood short cycle press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Real wood short cycle press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: Will the domestic air compressor model is how to divide, there is no fixed standard?. What's the model of DW-0.28/ (30-200) -250?

- Generally according to the air compressor power calculation, some according to kW, some according to horsepower, a little according to gas productionThere is no fixed standard, depending on the specific manufacturers

- Q: Air compressor high temperature, how's going on?

- The oil filter is dirty. When the oil filter in the compressor is too dirty, the resistance oil can not enter the compressor according to the normal flow. The compression opportunity will rapidly rise because of insufficient cooling oil. When the oil pressure difference exceeds 0.18Mpa, the filter element will need to be replaced.

- Q: What is the specific power of the air compressor?

- The calculation method of compressor power is a little complicated, mainly based on the theory of engineering thermodynamics..rn we usually say that the compressor power is the input power

- Q: How many kinds of 4 column hydraulic press? How much is the 100 ton?

- Four column hydraulic press mainly divides Y32, Y27, Y28 three series, according to the different processing technology division.The price of Y32-100 is about 50 thousand

- Q: Are air compressors and compressors the same equipment?

- Linear compressor adopts magnetic suspension principle and spiral ring hydro mechanical structure to compress gas and provide power for refrigeration.

- Q: How much is the injection pressure when the fuel air compressor is unloaded?

- 3Kg or less, minimum not less than 2.5Kg. When the air compressor is unloaded, the oil circuit will also play a role in cooling down because of the circulation of the oil circuit. Other air compressor manufacturers set different values, that is probably this value. You just take into account the pressure at this time is to meet the oil cycle, too high will make the machine running current and waste. I hope I can help you!

- Q: Air compressor trip problem

- Reason:1 because the starting current of the air compressor is relatively large, the current of the power switch is relatively small, and the starting current of the motor is not avoided;2 the motor has faulty grounding or interphase fault and short circuit;3. air compressor temperature is too high, also can cause tripping;4., the main engine is not running smoothly (due to poor environment, maintenance is not in place or bearing problems caused);

- Q: How to solve the air compressor high temperature?

- The most practical emergency treatment method for air compressor at high temperature: 1. Whether or not the oil level at the time of loading is out of range must be seen at loading time. If the oil level is not accurate when the engine is unloaded, because there is no oil in the pipeline, the oil is returned to the gas tank. You see a lot of it. (air compressor oil less) 2. check air compressor air filter. See if the filter is clogged. If it's a lot of ash, take the air gun out of it. Blow clean. (air filter blockage) 3. if air-cooled, take air gun to blow fan heater. The blockage of the fan will cause the oil to pass through the fan without waiting to be cooled, the oil temperature is high, and the air compressor temperature will be high. (cooler clogging) above means have been tried not to have the effect that is part of air compressor maintenance problems playing phone parts: 1. (oil filter plugging device plug) and oil cannot pass through the heat exchanger cooling fan, warm air compressor machine professional online cleaning agent is high. Change oil filter. 2. temperature control valve (control valve failure): air compressor starting when oil temperature is low, the temperature control valve is closed, the oil cannot pass heat exchanger cooling fan air compressor temperature not lower than 75 degrees lower than the long-term, there will be a lot of condensed water, condensed water more automatic drain valve, discharge condensate water will be in no hurry, oil and mixed together to see the water lubricated bearings, lubricating bearings, bearings will become what I did not say when the air compressor temperature to 80 degrees above the temperature control valve will automatically open the oil through the heat exchanger cooling fan, temperature drop.

- Q: How to determine the compressor is a few compression?

- The selection of air compressor is mainly based on the working pressure and flow of the pneumatic system.The working pressure of gas source should be about 20% higher than the maximum working pressure in pneumatic system, because the distance loss and local loss of the gas supply pipeline should be considered. If the work pressure in some parts of the system is low, a pressure reducing valve can be used to supply the gas. The rated exhaust pressure of air compressor is divided into low pressure (0.7~1.0MPa), medium pressure (1.0~10MPa), high pressure (10~100MPa) and ultra high pressure (over 100MPa), which can be chosen according to the actual demand. Common use pressure is 0.7-1.25.First of all, according to the characteristics of the air compressor requirements, select the type of compressor. Then, the output pressure PC and the suction flow QC of the air compressor are determined according to the two parameters of the working pressure and the flow rate required by the pneumatic system, and finally the model of the air compressor is selected.

- Q: The process and principle of laminator

- In order to make Pakistan block structure compact, Pakistan will block in a plastic film bag, vacuum sealed, placed in the container in the hot water, sealing the container pressure to 30Mpa above, structural elements in the water itself becomes loose after uniform compression is uniform and compact, ensure the consistency of the components of electrical performance index, effectively improve the quality of the products.

Send your message to us

CE Certificated Real Wood Short Cycle Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords