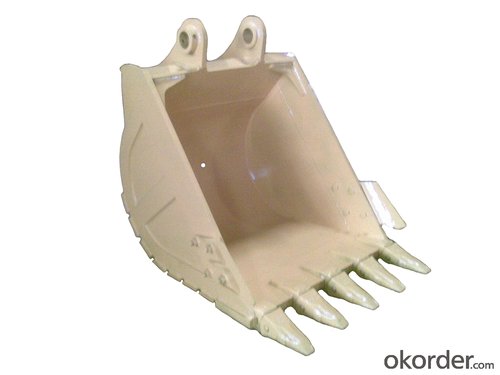

CATERPILLAR CAT320 excavator bucket CATERPILLAR excavator parts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

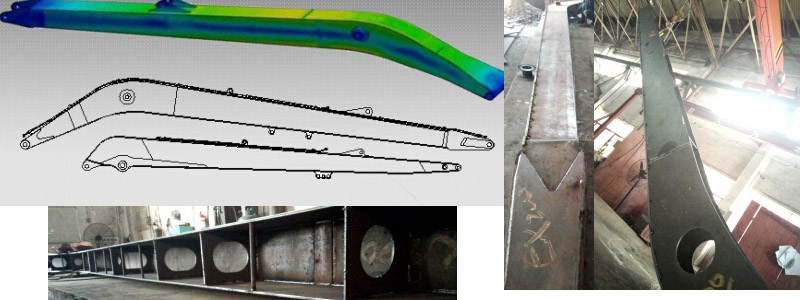

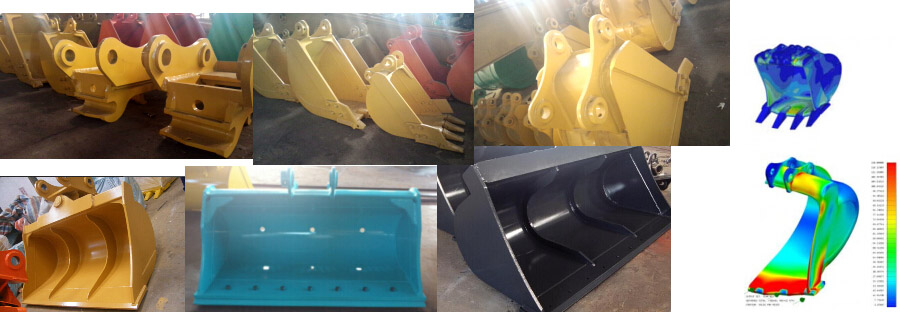

We can design and produce excavator buckets for all brands, scientifically solve stress problem as different construction conditions and customer requirements, and have ability to ensure structural strength, use performance and product quality by selection of high-quality material, advanced computer-aided design and complete control over process welding quality. The specification ranges from 0.1m3 to 12m3.

By bucket type and material, there are common bucket, imitated original bucket, reinforced bucket and rock bucket, which are made from domestic high-tensile structural steel 16Mn (Q345B), in addition, the tooth plate and side edge board of reinforced bucket and rock bucket can be made from domestic high-quality wear-resistant steel NM360 and Sweden ultrahigh-strength wear-resistant steel HARDOX according to customer demands.

By function, there are ditching bucket, grid bucket, cleaning bucket, and tipping bucket, etc. The ditching bucket is suitable for ditching in different forms, and is featured by once forming, no finish and high work efficiency. The grid bucket is used to separate, excavate or salvage bulk materials excellently at a time, and is widely applicable to municipal administration, agriculture, forestry, water conservation and earthwork, and cleaning bucket and tipping bucket are suitable for finishing of slop and other planes and huge desilting and cleaning of riverway and ditches, and the tipping bucket can change the dip angle of cleaning bucket by the hydro-cylinder, which greatly improves work efficiency.

By Material and Type

| Type | Material | Configuration and Performance | Application environment |

| common bucket | Q345B | Standard General-purpose Type, Standard Board Thickness, Single-layer Reinforcing Plate at Bottom, Homemade High-quality Bucket Tooth Seat; | Light working environment like excavation of clay and loose soil, and loading of sand, soil and gravel; |

| imitated original bucket | Q345B | Imitated Original Type, Standard Board Thickness, Single-layer Reinforcing Plate at Bottom, Homemade High-quality Bucket Tooth Seat; | Light working environment like excavation of clay and loose soil, and loading of sand, soil and gravel; |

| reinforced bucket | Q345B or | Thickened board, double-layer reinforcing plate at bottom, welded reinforcing plates at two sides, preventer plate installed on the side edge board, reinforced bucket tooth seat; | Common heavy-load working environment like excavation of pan soil mixed with broken stones or loading of broken stone or gravel; |

| rock bucket | Q345B or | Thickened board, double-layer reinforcing plate at bottom, welded reinforcing plates and creeper treads at two sides, preventer plate installed on the side edge board, special bucket tooth seat for rock bucket; strong wear resistance and bending resistance. | Heavy-load working environment like loading of broken stone, gravel, secondary hard rock, weathered granite and exploded ore; |

Comparison of Chemical Composition and Mechanical Performance of Material

| Material | Code | Main Chemical Composition | Brinell Hardness | Elongation δ | Tensile Strength σ | Yield Strength σ | ||||

| C | Si | Mn | P | S | ||||||

| Manganese Board | Q345B | 0.18 | 0.55 | 1.4 | 0.030 | 0.03 | 163~187 | 21 | 470~660 | 345 |

| Homemade Wear-resistant Board | NM360 | 0.20 | 0.3 | 1.3 | 0.020 | 0.006 | 360 | 16 | 1200 | 1020 |

| High-strength Wear-resistant Board | HARDOX500 | 0.20 | 0.7 | 1.7 | 0.025 | 0.010 | 470~500 | 8 | 1550 | 1300 |

- Q: Improve the excavator bucket teeth wearing resistance. Our country excavator bucket teeth service life is the main reason for the low in the following aspects: the structure design is not reasonable. Select material and heat treatment. No improper adopts the advanced surface anti-wear technology and operation and maintenance etc.

- ......ok. I'll take a guess at what you're asking. If youre wanting to know how to get longer life out of your teeth, why not just build them up with wear plate, or hard surface them? You never said what this excavator of yours is even. Big difference in what youre going to do with the baby teeth on a small excavator in the 110 and under range, versus the teeth on a 1200. if youre working in ground that will allow, you can take a length of flat cutting edge, say, from a dozer, and weld it across the face of the teeth. This gives a larger wear face, resulting in much longer life.

- Q: Everyone at work uses it but most of the people I know don't. I work in a marketing job and have resisted thus far because I'm uncomfortable with it and I don't like the industry and plan to get out of it. I have friends who have interesting jobs who aren't on it, ministers, marine researchers, alpine guides, excavator operators, theatrical production designers etc. Is Linked only for people with boring office jobs?

- Not okorder is better though

- Q: The county building code for my area specifies that the drain for my sump pump must be 10' from the property line. In order to meet that specification, and because the yard tends to be flat or uphill, I need to basically drain directly where the pipe comes out of my house. My gutter is also in that immediate area.I have an idea of how I want to drain both the gutter and sump pump that will eliminate concerns of ground erosion and avoid the accumulation of water in that immediate area, but I am looking for opinions.I plan to get a water deflector that directs the water 45 degrees opposed to one specificed direction. Then I plan to dig out an area around this spot that is maybe a foot deep and maybe a couple feet wide, put in erosion fabric, and backfill with rock. Is this my best option.I have no where to run a corrigated pipe and no down hill access

- Through my job as a pump serviceman I have come across many sumps ~ some containing just water many containing household sewerage. I think the best system I have ever seen has been a well consisting of 3 or 4 well liners sunk into the Ground with the dirt in the centre removed. The base of the holes were concreted with a flat base for the sewerage pump to sit on! The outlet pipe had a removable connection (eg; PVC socket union) then a 500 mm brass swing check valve a 50mm PVC pipe leading up to the town sewer. The pump has to be of enough capabilities to handle all the water from the home usage a heavy down pour should it rain. The sewerage pump operated on a float switch system. Around the base of the pump required stainless mesh although this one didn't have one co's it was for ever getting clogged up with women's used tampons. Some sewerage pumps have cutter blades in them this one didn't! The power cord came up out of the well was plugged into a water proof connection a bucket was placed over it! The top of the well liners can have a concrete slab or in this case was a huge piece of laminated plywood that was treated in case of water damage Cheers!

- Q: I'm looking for a 2.5 tire for a sick hefty AM almost FR hardtail...(probably a Transition Vagrant)... I wanted something wide, predictable and that would really hook up on just about everything... I couldn't decide between the 2 tires so I'm thinking maybe Kenda in the rear, WTB in the front???

- I love the Weirwolfs....not too crazy about them on the front because they kick up crap all over my legs, but it's a great tire. I run it on the rear. A couple friends of mine didn't like the way they cornered because they said they could feel the bumpiness of the gaps in the corner knobs....I've never noticed it and they do great for me. Excavators are pretty aggressive....very different than the Weirwolf. If you have loamy or sandy/loose soil they'll hook up great. Kinda rough on the trails, though, so if you don't need the big knobs, maybe gear down a notch. Maxxis Highrollers or WTB Prowlers are worth looking at, and there are still a lot of people riding IRC Trailbears, too. Intense makes some great tires....definitely worth looking at.

- Q: The throttle is 10 vehicles have been working for 100100 hours no repair engine. Now talk about the problem of holding back the car. In the car work, reporting will drop point by drop, resulting in fire fighting. When driving uphill, hold back to extinguish the fire. The work is in small hard tired things will have to fire. The parts of the 2 hydraulic pumps have been cleaned. But it still does not work, the car reported at work when the gap is great. Very unstable. Does the problem relate to high pressure pumps or to hydraulic pumps? Is it caused by power mismatch, or what's wrong?. StopThe car is Hitachi 330. Direct fired. OK, on the downhill, the car will go off. Sometimes the 2 sides stop together and get stuck. Just shake it and make it work.

- Since your engine has been running a little bit longer, check the oil pump first. If it doesn't solve the problem, you're going to fix the engine! 2, your chain is badly worn

- Q: The boom cylinders (2) of a 350D LC John Deere excavator have a bore diameter of 145 mm and a stroke of 1520mm. The hydraulic pressure of the system can be boosted up to 36.3 MPa when breaking hard ground or lifting wet sand or gravel. What is the maximum extending speed of both cylinders. Assume all the engine power of 202 kW is converted into hydraulic power.I got 0.17 m/s but wanted to make sure if thats right. If you can show the step by step method of solving this problem. I would greatly appreciate it.thank you.

- The basic formula for hydraulic power is proportional to the force and the flow. We can calculate from the power to find time and so speed. This is: power_watts = (force_newtons x displacement_meters) / time_seconds We need the time so: time = (force * displacement) / power The pressure is due to the resistance to flow. Determine the force from the pressure and the cross sectional area of the cylinder, where one pascal is one newton per square meter. area = pi * r^2 = pi * 0.0725m^2 = 0.016513m^2 The pressure is 36.3MPa. The force is: Force = pressure * area = 599422N. The displacement is the stroke of 1.52m, so from the above formula for time: time = (599422N * 1.52m) / 202000W = 4.51s The extension speed (velocity) is: velocity = distance / time = 1.52m /4.51s = 0.337m/s Edited later: I missed the point there are 2 cylinders. As there are 2 cylinders for the same flow, the speed is half of one cylinder: 0.337 / 2 = 0.1685m/s <== Answer (as for your answer)

- Q: how did the Egyptians influence the Minoans and the Mycenaeans?

- England became into nevertheless in a hunter/gatherer subculture with the 1st little bit of farming. by way of fact the middle East became into warmer and had longer turning out to be seasons, it progressed first. the rich Nile Delta became into waiting to maintain a great inhabitants while individuals in England had to maintain shifting the place the sport became into or the grazing. once you have a inhabitants planting fields, you apart from would ought to stay interior of attain to guard those fields. by way of fact which you're no longer shifting a week or so, you have extra possessions so human beings started making issues. Pottery, papyrus, woven fabric, rings.....

- Q: Im doin a CERT 3 in civil Construction and I Gain a Excavator TicketSkid Steer TicketBackhoe TicketI have HR licence White Card Traffic Controlle Ticket and cant Get a Job How I Gain experience When I cant Get a Go ???

- Join the Operating Engineers Union. google it.

- Q: I have a 2004 Chevy 1500 LS extended cab z71 package with the 5.3l. This truck has the towing package such as transmission cooler factory class five hitch and 87k miles and I believe 3.73 axle ratio. I'm wondering if I can tow a 7000lb excavator plus trailer on a short trip 10-15 miles with only one somewhat major grade. I'm planning on having to take it really easy on the truck but just curious if I should forget the idea all together.

- It'll pull it. Use tow-haul and take it easy, but it'll do it.

- Q: 1) what type of lever is the bucket on the dragline excavator attached to? where is its fulcrum?2) identify any pulley systems in dragline excavator. What are their functions3) the bucket of a power shovel is smaller than that on a dragline excavator. Why?4)what types of levers can you see in the power shovel? where are their fulcrums?5) since the load in the bucket requires so much engine power, why don't the engineers include many more pulleys? (Hint: consider the force acting between each cable and the surface of each pulley).6)

- Here okorder /

Send your message to us

CATERPILLAR CAT320 excavator bucket CATERPILLAR excavator parts

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords