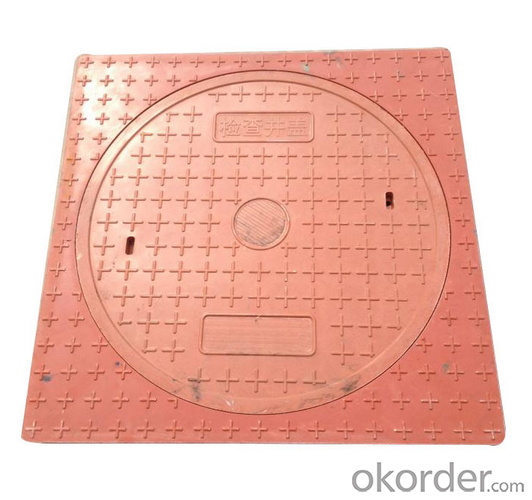

Casting Ductile Iron Manhole Covers C250 for Mining with Frames

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) Service:OEM

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5) we can produce as per customers'drawings

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| SC42 | C250 | 330*330 | 420*420 |

| RGC-01L | C250 | 390*325 | 530*465 |

Advantages

Good compressive, flexible and impact strength, water-proof, not rust, serviceable life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get a discount?

A: Yes, we can offer you a 10% discount if your order comes up to 300 sets.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- Please consider the following points:1, batch: if the product batch is very large, casting will certainly have advantages, cost sharing will be very low. If less, it is recommended to use weldments.2. Reinforcement structure: if the structure is relatively simple, it is recommended to use welded parts, complex, preferably casting.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The main content of red sand table (Institute of soil science, China) silica 79.4%. three 1.48%. three 10.55%. two aluminum oxide iron oxide, calcium oxide 0.85%. Magnesium Oxide 0.52%. 1440. refractory mud 3.06% LOI 1.98% red sand with high silicon content, permeability is strong, durable, high refractoriness, good angle, low moisture content, less mud the casting finish is high, the basic requirements of sand should meet the following requirements: Casting of high purity and cleanliness, with silica sand as an example, iron sand SiO2 content of more than 90%, the big steel casting requests the SiO2 content of more than 97%; the high refractoriness and thermal stability; the suitable particle the shape and particle composition; it is not easy to be wetted by the liquid metal; cheap. The particle shape and composition of casting sand particle shape and particle composition permeability properties such as mobility, sand compaction, permeability, strength and resistance to liquid metal effects, is an important indicator of the quality of casting sand.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Problem one,1, according to drawings, castings, material requirements and machine power, choose the right diameter of roughing tools, and can process this material blade type.2, according to the actual size of the casting blank, calculate the number and path of the knife, pay attention to small cutting depth, large feed, cutting width, to ensure that the tool diameter 80 - 90%, the amount of not full knife cutting, this tool and machine tool damage.Question two,If they can not change the casting blank allowance under the condition that the quantity large diameter cutter, such as milling cutter main angle 7560 degrees can give reasonable processing parameters, the same cutting depth should not be too large, because in the same machine power, tool diameter increases, cutting depth will need smaller.

Send your message to us

Casting Ductile Iron Manhole Covers C250 for Mining with Frames

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords