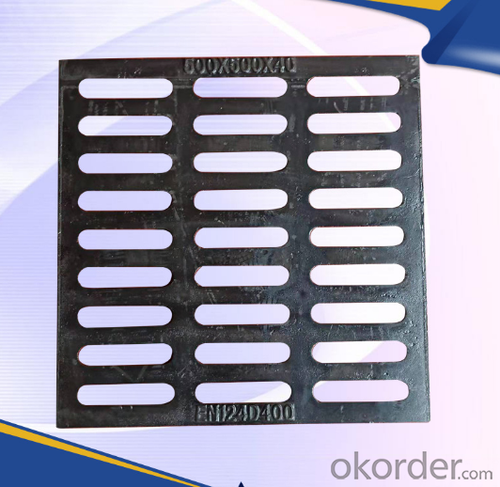

Casting Ductile Iron Manhole Covers C250 B125 for Mining and construction with Frames

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Service: OEM

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) |

| RGC-01L | C250 | 390*325 | 530*465 |

1.Applicable medium:gases,liquids,steam

2.Materail:ductile iron,Gray cast iron

Tested item standad

Anti-breaking strength (Mpa)>14

Impact toughness resistance (kg/cm2)>95

Tensile strength (Mpa)>10

Compressive strength (Mpa)>30

Modulus of elasticity(kg/cm2)>1.4*104

Cold-hot resistance measure<0.4

Water-absorption<1.0

Surface treatment

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

How do we start our cooperation?

If you are wholesaler, please send us the detailed information of the products you are doing, like Cover size, clear opening size, loading Grade, we will give you our best advices. We can start from sample order.

Sometimes if meet the size we don’t have, the new mould with your size and design can be considered from us. Let's talk more details about the New Mould and Charges. Then start our Cooperation.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: What are the casting parts processing engineering?

- Among them, special casting has metal mould casting, pressure casting, low pressure casting, lost wax casting (also known as precision casting), shell casting, lost foam casting, centrifugal casting, continuous casting, V casting, and clay casting

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- It has something to do with the size of your work, and it has a lot to do with the blade you're using right now.

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Casting Ductile Iron Manhole Covers C250 B125 for Mining and construction with Frames

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords