Seamless Steel Pipe Widely Used Multi Models

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Seamless Steel Pipe Description:

Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2、Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

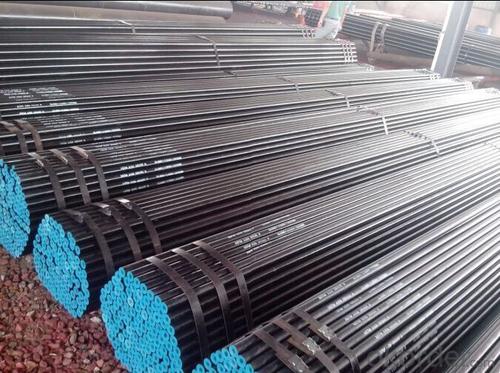

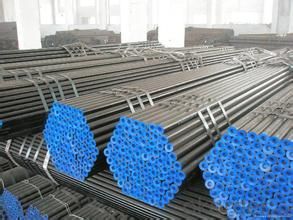

3、Seamless Steel Pipe Images:

Packaging & Delivery

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4、Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

5、FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

- Q: What time what time for gas pipeline steel pipe PE pipe

- PE pipe is suitable for medium voltage and low voltage 0.4MPa below the pressure pipe wall thickness. According to the different pressure is not the same, so the steel tube can be used for high pressure.

- Q: Are steel pipes fire-resistant?

- Yes, steel pipes are generally fire-resistant. Due to their high melting point and low flammability, steel pipes can withstand high temperatures and prevent the spread of fire.

- Q: How are steel pipes coated for insulation purposes?

- Various methods and materials are commonly used to coat steel pipes for insulation. One method involves applying a thermal insulation coating, typically made of a high-performance polymer or epoxy-based material, to the surface of the pipe. To ensure proper adhesion of the coating, the steel pipe is first thoroughly cleaned to remove dirt, grease, and rust. This cleaning process, known as abrasive blasting, involves propelling small particles at high speed to remove contaminants and create a clean, rough surface. Once the surface is prepared, the thermal insulation coating is applied using techniques such as spraying, brushing, or rolling. Multiple layers of the coating are carefully applied to ensure adequate coverage and thickness. This forms a protective barrier between the steel pipe and the external environment, preventing heat transfer and reducing energy loss. In addition to thermal insulation coatings, steel pipes can also be coated with materials like polyurethane foam or mineral wool. These materials offer excellent thermal insulation properties and are often used in applications where high-temperature resistance is necessary. Overall, the insulation of steel pipes involves a combination of surface preparation and the application of specialized coatings. These coatings serve to minimize heat loss, improve energy efficiency, and protect against corrosion and other environmental factors.

- Q: What are the factors that affect the pressure rating of steel pipes?

- The pressure rating of steel pipes can be influenced by various factors. These factors include the strength of the material used, the thickness of the pipe wall, the diameter of the pipe, the temperature at which it operates, its resistance to corrosion, compliance with manufacturing standards, and the impact of external loads. The strength of the steel plays a crucial role in determining the pressure rating. Steel with higher strength can handle higher pressure levels, while weaker grades may have lower ratings. Thicker walls provide more resistance against internal forces, allowing pipes to handle higher pressures. The diameter of the pipe also affects its pressure rating. Larger pipes generally have higher ratings due to their larger cross-sectional area. High temperatures can weaken steel, reducing its strength and pressure rating. Therefore, maximum operating temperature should be considered. Corrosion can weaken the pipe material over time, leading to a decrease in pressure rating. Factors such as fluid type, pH levels, and environmental conditions can impact corrosion resistance. Compliance with industry standards is crucial in determining pressure ratings. These standards ensure proper manufacturing techniques and materials are used. External loads such as soil settlement or traffic can affect pressure ratings. Proper design, installation, support, and protection are necessary to maintain the pressure rating. Considering all these factors and consulting industry guidelines is important for determining appropriate pressure ratings for steel pipes in different applications.

- Q: What are the industries that commonly use steel pipes?

- Some of the industries that commonly use steel pipes include construction, oil and gas, water and wastewater treatment, mining, manufacturing, automotive, and infrastructure development.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes such as supporting the turbine structure, housing electrical cables, and transporting fluids like hydraulic oil and cooling water. These pipes provide structural strength, corrosion resistance, and durability, ensuring the stability and functionality of the turbines in the harsh offshore environment.

- Q: How is the steel pipe dance installed at home?

- Portable pipe with instructions and CD can be installed, portable steel pipe of a new patent, convenient installation, no restriction site, no drilling, readily removable, adjustable height, stainless steel, solid.

- Q: How do you calculate the pipe pressure loss coefficient for steel pipes?

- To calculate the pipe pressure loss coefficient for steel pipes, you can use various empirical equations or reference charts specific to the pipe type and size. These equations and charts take into account factors such as pipe roughness, Reynolds number, and flow rate to determine the pressure loss coefficient. It is important to consult relevant engineering references or software to accurately calculate this coefficient for steel pipes.

- Q: Water, gas, steel pipes, thick steel wire means?

- Often used in water, heating, gas, compressed air and vacuum lines. Can be used in pressure gauge pressure of 0.6 MPa (6 atm) steam pipe and condensate pipeline below, can also be used for conveying non erosive and non flammable and explosive media. Is divided into ordinary (working pressure is 1 MPa pressure gauge, 10) and strengthening (working pressure gauge is 1.6 MPa, 16 ATM) two. Galvanized white iron tube (galvanized iron tube). Non galvanized black iron pipe (black pipe).

- Q: What is a steel pipe?

- A steel pipe is a cylindrical hollow tube made primarily of steel, commonly used for transferring fluids and gases, as well as structural applications in construction and industrial settings.

Send your message to us

Seamless Steel Pipe Widely Used Multi Models

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords