CARBON STEEL PIPE FITTING TEE CNBM 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

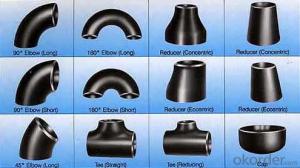

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: How are steel pipes used in the construction of desalination plants?

- Steel pipes are commonly used in the construction of desalination plants for various purposes. They are primarily utilized for the transportation of seawater and brine, as well as for the distribution of fresh water throughout the plant. Steel pipes are preferred due to their durability, corrosion resistance, and ability to withstand high pressure and extreme temperatures. Additionally, they can be easily welded together, allowing for efficient installation and maintenance.

- Q: What are the safety regulations for working with steel pipes?

- The safety regulations for working with steel pipes may vary depending on the specific circumstances and location, but some common safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper handling techniques to prevent injuries, using proper lifting equipment to prevent strain or back injuries, implementing proper ventilation and respiratory protection when working in confined or poorly ventilated spaces, and following proper procedures for welding, cutting, or bending steel pipes to minimize the risk of fire or explosions. It is essential to consult and adhere to local safety regulations and guidelines to ensure a safe working environment when dealing with steel pipes.

- Q: How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes are generally considered to be stronger and more durable compared to materials like PVC or copper. While PVC pipes are lightweight and easy to install, they are not as strong as steel and can be more prone to cracking or breaking. Copper pipes, on the other hand, are known for their corrosion resistance and are commonly used for plumbing systems. However, steel pipes have the advantage of being highly resistant to extreme temperatures, pressure, and damage, making them suitable for a wide range of applications, including industrial and commercial use.

- Q: How long do steel pipes typically last?

- Steel pipes typically last for several decades to over a century, depending on factors such as the quality of the steel, environmental conditions, and maintenance practices.

- Q: What are the different types of steel pipe coatings for underground applications?

- There are several types of steel pipe coatings used for underground applications, including fusion bonded epoxy (FBE), coal tar enamel (CTE), polyethylene (PE), and polyurethane (PU). These coatings provide corrosion protection and increase the lifespan of the steel pipes in underground environments.

- Q: What is the process of coating steel pipes?

- The process of coating steel pipes involves applying a protective layer on the surface of the pipe to prevent corrosion and increase its durability. This typically includes cleaning the pipe to remove any contaminants, followed by applying a primer to improve adhesion. The pipe is then coated with a layer of paint or a specialized coating material using a variety of techniques such as spraying, dipping, or electrostatic application. The coated pipe is then cured or dried to ensure the coating adheres properly. This process helps to ensure the longevity and performance of steel pipes in various applications.

- Q: Are steel pipes suitable for solar power plants?

- Indeed, solar power plants find steel pipes to be a fitting choice. Owing to their enduring nature, resilience, and ability to resist corrosion, steel pipes are commonly employed in the construction of solar power plants. They serve diverse purposes within these plants, encompassing the conveyance of fluids like water or heat transfer fluids, as well as proffering structural reinforcement for solar panels and other apparatus. Steel pipes excel at enduring high temperatures and pressure, thus rendering them an optimal choice for the efficient functioning of solar power plants. Moreover, steel pipes are readily obtainable and cost-effective, thereby establishing their popularity in the construction of solar power plants.

- Q: How do steel pipes handle abrasive materials?

- Steel pipes are highly durable and resistant to abrasion, making them well-suited to handle abrasive materials. The smooth interior surface of steel pipes minimizes friction and wear caused by the movement of such materials, ensuring their efficient and effective transportation.

- Q: Can steel pipes be used for conveying hazardous materials?

- Steel pipes can be used for conveying hazardous materials, as they are strong, durable, and resistant to corrosion. However, it is essential to consider the specific properties and compatibility of the hazardous material with steel to ensure safe transportation, as some chemicals or substances may react with steel or pose additional risks. Proper precautions, such as appropriate lining or coating, should be taken to minimize any potential hazards during transportation.

- Q: How are steel pipes used in the manufacturing of hydraulic systems?

- Steel pipes are commonly used in the manufacturing of hydraulic systems due to their durability, strength, and resistance to high pressure. These pipes are used to transport hydraulic fluids, such as oil or water, throughout the system, ensuring the smooth operation of various components, such as pumps, valves, and cylinders. The steel pipes provide a reliable and leak-free connection between these components, allowing for efficient transfer of power and control in hydraulic systems.

Send your message to us

CARBON STEEL PIPE FITTING TEE CNBM 2''-48''

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords