Schedule 40/80 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

1. Commodity Name: Carbon Seamless Steel Pipe

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

Length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. Application:

Carbon seamless steel pipes are applicable to gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C or T/T

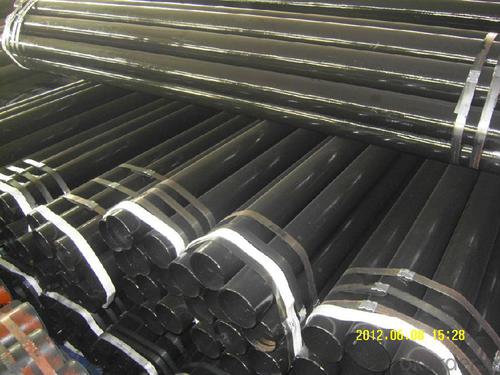

8. Packing and Shipment

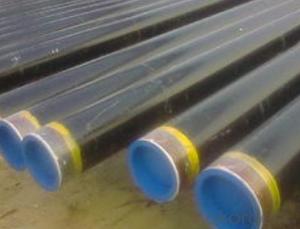

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

Seamless Steel Tubes Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q: How do you prevent steel pipes from rusting?

- To prevent steel pipes from rusting, various measures can be taken. One effective method is to apply a protective coating on the surface of the pipes. This can be done using different types of coatings such as paint, epoxy, or zinc. These coatings act as a barrier between the steel and the corrosive environment, preventing moisture and oxygen from coming into direct contact with the metal and causing rust. Another approach is to use corrosion inhibitors. These substances are added to the water or fluid flowing through the pipes to create a protective film on the steel's surface. This film acts as a shield, inhibiting the corrosion process and preventing rust formation. Regular maintenance is crucial in preventing rust on steel pipes. This includes inspecting the pipes for any signs of damage or corrosion and promptly repairing or replacing any compromised areas. Additionally, keeping the pipes clean and dry by removing any accumulated dirt or moisture helps to prevent rust formation. In some cases, it may be beneficial to use stainless steel pipes instead of regular steel. Stainless steel contains chromium, which forms a passive oxide layer on the surface of the metal. This layer acts as a natural barrier against corrosion, making stainless steel pipes highly resistant to rust. Lastly, controlling the environment in which the pipes are installed can also help prevent rust. This can be achieved by maintaining proper ventilation, controlling humidity levels, and avoiding exposure to harsh chemicals or corrosive substances. By implementing these preventive measures, the lifespan and integrity of steel pipes can be significantly extended while minimizing the risk of rust formation.

- Q: How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into three categories: schedule, standard, and extra strong.

- Q: What is the typical length of a steel pipe?

- The typical length of a steel pipe can vary depending on its purpose and application. However, standard lengths for steel pipes commonly range from 18 feet to 40 feet.

- Q: What is an electric welded pipe (EFW)? Seek help!

- According to the operation requirements of the electric welding machine, connect the lead wire and set up the proper welding parameter of the electric welding machine, which can be operated by manual or automatic two input methods.After checking, start the electric welding machine and enter the welding process. When the welding time is reached, the machine will automatically enter the cooling state.When the pipe completely removed after cooling, electric fusion welding machine.Cutting the pipe with the cutting tool of plastic pipe or fine toothed saw with cutting guide device, and making its end face perpendicular to the axis of pipe. Remove the edges of the edges with a knife, scrape the weld area in the pipe or spigot end and clean the weld area.Should use the special fixture as far as possible to secure the components to be connected, and the roundness of the pipe shall not exceed 1.5% of the outer diameter of the pipe, or it should be corrected on the corresponding fixture.

- Q: Can steel pipes be used for conveying slurries or abrasive materials?

- Yes, steel pipes can be used for conveying slurries or abrasive materials. Steel pipes are known for their durability and resistance to wear and tear, making them suitable for handling abrasive substances. Additionally, their smooth interior surface reduces friction, preventing clogging and ensuring efficient flow of slurries or abrasive materials.

- Q: How do you calculate the pipe flow rate for steel pipes?

- To calculate the pipe flow rate for steel pipes, you can use the Hazen-Williams equation or the Darcy-Weisbach equation. These equations take into consideration factors such as the pipe diameter, length, roughness, and the pressure difference between the two ends of the pipe. By plugging in these values into the respective equation, you can determine the flow rate of the fluid passing through the steel pipe.

- Q: Theoretical weight of 25*25*1.5 square steel tubes

- The theoretical weight of 25*25*1.5 square steel tubes is 1.075kg/m.

- Q: Can steel pipes be used for petrochemical plants?

- Yes, steel pipes can be used for petrochemical plants. Steel pipes are commonly used in petrochemical plants due to their high strength, durability, and resistance to corrosion. They can handle high-pressure and high-temperature applications, making them suitable for transporting various chemicals and gases in petrochemical processes.

- Q: Are steel pipes suitable for underground mining applications?

- Yes, steel pipes are suitable for underground mining applications. Steel pipes have been widely used in the mining industry for various purposes such as water supply, ventilation, and conveyance of materials. The strength and durability of steel pipes make them suitable for the harsh and demanding conditions of underground mining. Steel pipes are known for their high tensile strength, which allows them to withstand the pressure and stress exerted by the surrounding rock and earth in underground mining operations. They can handle heavy loads, making them suitable for transporting materials and supporting structures in mining tunnels. Additionally, steel pipes are resistant to corrosion, which is crucial in underground mining where moisture and various chemicals are present. Their corrosion resistance ensures the longevity and reliability of the pipes, reducing the need for frequent replacements and maintenance. Furthermore, steel pipes can be easily welded and joined, allowing for customization and flexibility in designing underground mining systems. They can be adapted to various shapes and sizes to meet specific mining requirements. In conclusion, steel pipes are highly suitable for underground mining applications due to their strength, durability, corrosion resistance, and versatility. They have been proven to be effective in supporting mining operations and ensuring the safety and efficiency of underground mining processes.

- Q: What are the factors to consider when selecting steel pipes?

- Some factors to consider when selecting steel pipes include the intended application and environment, the required strength and durability, the size and thickness of the pipes, the corrosion resistance, the cost, and the availability of different types of steel pipes.

Send your message to us

Schedule 40/80 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords