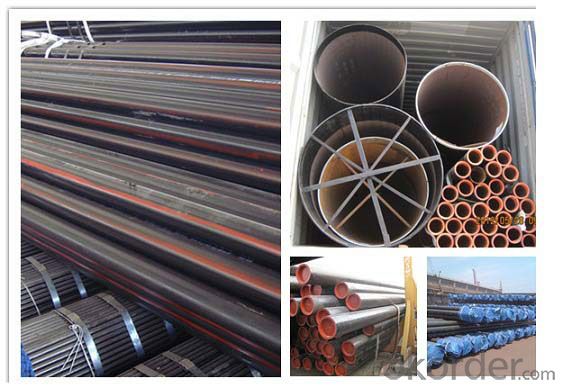

Steel pipe for carbon seamless ,ST35-ST52, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: 6 - 50 mm Section

Shape: Round

Outer Diameter: 33 - 600 mm

Secondary Or Not: Non-secondary

Application: Fluid Pipe

Technique: Hot Rolled,Hot Rolled,Cold Drawn,Hot Expanded Certification: API Surface Treatment: Beveled end or plain end or varnished as per buyer

Special Pipe: API Pipe Alloy Or Not: Non-alloy

Brand Name: XPY(Xinpengyuan)

Length: 6-12m or according to clients' requirements

Standard: BS 3059-2,JIS G3454-2007,GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB 6479-2000,DIN 1629/3,DIN 2448,ASTM A106-2006,ASTM A53-2007,API 5CT,API 5L,BS,JIS,GB,DIN,ASTM,API

Grade: 20#,45#,15CrMo,12Cr1MoV,16Mn,A53(A,B),A106(B,C),API J55,API K55,API N80,API P110,St52,St45,Q235,Q345,10#-45#,Cr-Mo alloy,A53-A369,API J55-API P110,ST35-ST52,Q195-Q345

Packaging Detail: Beveled end , plain end, varnished, or adding plastic caps/ according to customers' request

Bundles or loose, each bundles with 8 steel strips and

nylon slings wrapped with water proof plastic cloth.

We also pack our products according to customer’s requirement

- Q: Can steel pipes be used in the oil and gas industry?

- Indeed, the oil and gas industry commonly utilizes steel pipes. Renowned for their robustness, longevity, and resistance to corrosion, steel pipes are well-suited for the transportation and storage of diverse fluids and gases within this sector. They possess the ability to endure high pressure and extreme temperatures, which are frequently encountered during oil and gas operations. Moreover, the ease with which steel pipes can be welded together facilitates efficient assembly and maintenance. Consequently, steel pipes represent a dependable and economically sound option for the oil and gas industry.

- Q: How are steel pipes coated for insulation purposes?

- Various methods and materials are commonly used to coat steel pipes for insulation. One method involves applying a thermal insulation coating, typically made of a high-performance polymer or epoxy-based material, to the surface of the pipe. To ensure proper adhesion of the coating, the steel pipe is first thoroughly cleaned to remove dirt, grease, and rust. This cleaning process, known as abrasive blasting, involves propelling small particles at high speed to remove contaminants and create a clean, rough surface. Once the surface is prepared, the thermal insulation coating is applied using techniques such as spraying, brushing, or rolling. Multiple layers of the coating are carefully applied to ensure adequate coverage and thickness. This forms a protective barrier between the steel pipe and the external environment, preventing heat transfer and reducing energy loss. In addition to thermal insulation coatings, steel pipes can also be coated with materials like polyurethane foam or mineral wool. These materials offer excellent thermal insulation properties and are often used in applications where high-temperature resistance is necessary. Overall, the insulation of steel pipes involves a combination of surface preparation and the application of specialized coatings. These coatings serve to minimize heat loss, improve energy efficiency, and protect against corrosion and other environmental factors.

- Q: Can steel pipes be used for underground water supply systems?

- Yes, steel pipes can be used for underground water supply systems. Steel pipes are durable, strong, and can withstand harsh conditions, making them suitable for underground installations. Their corrosion resistance properties and ability to withstand high pressure make them a reliable choice for transporting water underground.

- Q: How are steel pipes protected against chemical corrosion?

- Steel pipes are protected against chemical corrosion through various methods such as coating them with corrosion-resistant materials like epoxy or polyethylene. Additionally, cathodic protection techniques like applying sacrificial anodes or using impressed current systems can also be employed to prevent chemical corrosion on steel pipes.

- Q: What are the different joining methods for steel pipes?

- There are several different joining methods for steel pipes, including welding, threading, flanging, and mechanical coupling.

- Q: How do you repair a damaged steel pipe?

- To repair a damaged steel pipe, the first step is to identify the extent of the damage. If the damage is minor, it can be fixed using a pipe repair clamp or a stainless-steel wrap. For larger damages, a cut and replace method may be necessary, where the damaged section is cut out and replaced with a new piece of pipe. In some cases, welding or soldering techniques may be required. It is important to consult with a professional plumber or pipe repair specialist to ensure the correct repair method is used for the specific situation.

- Q: What is the thickness of steel pipes?

- The thickness of steel pipes varies depending on the specific application and type of pipe used. Typically, steel pipes are available in various thicknesses, measured by their schedule or wall thickness. Schedule 40 is the most common schedule for steel pipes, known for its standard wall thickness. However, for applications demanding higher strength or pressure resistance, thicker pipes with higher schedules like Schedule 80 or Schedule 160 are also available. Moreover, the thickness of steel pipes can be tailored to meet specific project requirements.

- Q: What are the factors to consider while selecting steel pipes for a project?

- When choosing steel pipes for a project, there are several key factors to take into account. These factors encompass the material composition of the steel, the dimensions of the pipes, the intended use, the environmental conditions, and the allocated budget. Firstly, the material composition of the steel pipes plays a vital role in determining their strength, resistance to corrosion, and overall durability. Carbon steel, stainless steel, and alloy steel are commonly used types of steel for pipes, each possessing unique characteristics suitable for different applications. Secondly, the dimensions of the pipes, including diameter and wall thickness, should be carefully considered. It is crucial to ensure that these dimensions align with the project requirements and the system in which the pipes will be installed. This ensures that the selected pipes can effectively handle the required flow rates and pressures. Thirdly, thorough assessment of the intended application of the steel pipes is necessary. Different projects may demand pipes with specific features, such as heat resistance, pressure resistance, or the ability to transport particular substances like gas, oil, or water. Understanding these application requirements aids in selecting the appropriate type of steel pipes. Evaluation of the environmental conditions in which the pipes will be installed is also important. Factors such as temperature fluctuations, exposure to moisture, corrosive substances, and external pressures must be taken into account. For example, if the project involves underground installation or exposure to corrosive chemicals, corrosion-resistant steel pipes may be necessary. Lastly, the allocated budget for the project is a significant consideration. The cost of steel pipes can vary depending on their material composition, dimensions, and additional features. Striking a balance between project requirements and available budget ensures cost-effectiveness without compromising the quality and performance of the pipes. In conclusion, the selection of steel pipes for a project necessitates careful consideration of factors including material composition, pipe dimensions, intended application, environmental conditions, and budget. By thoroughly evaluating these factors, one can choose the most suitable steel pipes that meet project requirements, ensuring long-term performance and durability.

- Q: How are steel pipes protected against electromagnetic interference?

- Steel pipes can be protected against electromagnetic interference by using a variety of methods such as shielding, grounding, and insulation. Shielding involves wrapping the pipes with a conductive material, like copper or aluminum, which acts as a barrier to block electromagnetic waves. Grounding ensures that any stray electrical charges are safely directed away from the pipes, reducing the risk of interference. Insulation, such as coatings or sleeves, can also be applied to prevent direct contact between the pipes and potential sources of electromagnetic interference.

- Q: How are steel pipes used in automotive manufacturing?

- Steel pipes are commonly used in automotive manufacturing for various applications such as exhaust systems, fuel lines, and structural components. They provide durability, strength, and corrosion resistance, making them suitable for withstanding the harsh conditions and high temperatures associated with automotive operations. Additionally, steel pipes offer flexibility in design and can be easily formed and manipulated to meet specific requirements, ensuring efficient and reliable performance in vehicles.

Send your message to us

Steel pipe for carbon seamless ,ST35-ST52, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords