2''-48'' INCH CARBON STEEL PIPE FITTING TEE CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Detailed Description

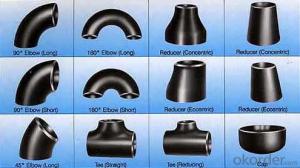

Products | pipe fittings elbows, bends,tees, reducers caps |

Size | 1/2" - 48" |

Wall thickness | Sch5-Sch160 XXS |

Standard | ANSI, ASME API5L, OCT, DIN and JIS, etc. |

we can also produce according to drawing and standards provided by customers. | |

Material | Carbon steel, alloy steel and stainless steel. |

We can produce according to materials appointed by consumers. | |

Packaging | Plywood Cases,plywood pallet, plastic bag or as customers requirement |

Surface Treatment | Shot blasted, rust-proof black oil |

Delivery Time | 10-60 days |

Quality | First grade |

Others | 1.Special design available according to your drawing. |

2.anti-corrosion and high-temperature resistant with black painting | |

3. All the production process are made under the ISO9001:2000 strictly. | |

4. A conformity rate of ex-factory inspection of products. |

Specifications

Ansi B16.9 WPB carbon steel pipe fitting elbow tee reducer

Size:Seamless 1/2"-24" Welded 1/2"-48"

ANSI B16.9 WPB carbon steel pipe fitting elbow tee reducer

1.Size: Seamless 1/2"-24" Welded 1/2"-48"

2. WT: SGP, STD, SCH40, SCH80, SCH100,SCH120,SCH160,XS,XXS

3. Material:

stainless steel Grade: 201,304,304L,316,316L,317,317L,904L,and etc

carbon steel Grade: WPB,GRB, Q235,16MN

Alloy steel: st35.8,st52,wp11,wp22,wp12 wp l6

4. Standard: ASTM/AISI/DIN/JIS

5. Type: Concentric and eccentric

6. Surface treatment: Transparent oil, rust-proof black oil

7. Applications range: Applications range: for use in the petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment,aviation, boiler heat exchanger, and other fields

8. Packing: wooden case or as per customers' requirement

- Q: What are the common methods of joining steel pipes?

- The common methods of joining steel pipes include welding, threading, and using mechanical couplings. Welding involves fusing the pipes together using heat, while threading involves screwing the pipes together using threads on the ends. Mechanical couplings are devices that connect the pipes together using compression or other means.

- Q: Can steel pipes be used for underground stormwater systems?

- Yes, steel pipes can be used for underground stormwater systems. Steel pipes are known for their durability and strength, making them suitable for withstanding the pressure and weight of underground stormwater systems. Additionally, steel pipes have a high resistance to corrosion, which is important when dealing with stormwater that may contain various contaminants. However, it is important to properly coat and protect the steel pipes to prevent any potential corrosion or damage over time. Regular maintenance and inspections should also be carried out to ensure the integrity of the steel pipes and the overall performance of the underground stormwater system.

- Q: What are the different methods of pipe coating for steel pipes?

- There are several different methods of pipe coating for steel pipes, each with its own advantages and applications. One common method is fusion bonded epoxy (FBE) coating. This involves heating the steel pipe and applying a thermosetting powder that melts and adheres to the surface, creating a strong and durable coating. FBE coating provides excellent corrosion protection and is commonly used in the oil and gas industry. Another method is liquid epoxy coating. This involves applying a liquid epoxy resin to the surface of the steel pipe, which then cures and forms a protective barrier. Liquid epoxy coating is often used for smaller diameter pipes and provides good chemical resistance. Polyethylene (PE) coating is another popular method, particularly for pipelines that will be buried underground. PE coating involves wrapping the steel pipe with a layer of polyethylene, which provides excellent resistance to water, chemicals, and abrasion. Polyurethane (PU) coating is another option, offering a high level of chemical resistance and flexibility. It is typically used for offshore applications and in environments with extreme temperatures. Other methods of pipe coating include coal tar enamel (CTE) coating, which provides excellent resistance to water and chemicals, and concrete weight coating, which adds weight to the pipe to ensure stability in underwater or subsea applications. In summary, the different methods of pipe coating for steel pipes include fusion bonded epoxy (FBE), liquid epoxy, polyethylene (PE), polyurethane (PU), coal tar enamel (CTE), and concrete weight coating. The choice of coating method depends on the specific requirements of the application, such as corrosion protection, chemical resistance, or stability.

- Q: Can steel pipes be used for transporting hazardous materials?

- Yes, steel pipes can be used for transporting hazardous materials. Steel is highly durable and can withstand the pressure and temperature requirements of hazardous material transportation. Additionally, steel pipes can provide a reliable barrier against leaks and spills, minimizing the risk of environmental contamination. However, it is essential to consider the specific properties and compatibility of the hazardous material being transported to ensure the steel pipes are suitable for the task.

- Q: What is the difference between steel pipes and concrete pipes?

- Steel pipes and concrete pipes differ in their composition, construction, and characteristics. Steel pipes are made from steel, whereas concrete pipes are made from a mixture of cement, sand, aggregate, and water. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for high-pressure applications and underground installations. Concrete pipes, on the other hand, are renowned for their affordability, ease of installation, and resistance to fire. They are commonly used in stormwater drainage systems and sewerage networks. Overall, the choice between steel pipes and concrete pipes depends on the specific requirements of the project, such as budget, load-bearing capacity, and environmental factors.

- Q: Can steel pipes be used for underground oil and gas pipelines?

- Yes, steel pipes are commonly used for underground oil and gas pipelines due to their durability, strength, and resistance to corrosion.

- Q: Can steel pipes be used for conveying corrosive substances?

- When conveying corrosive substances, it is crucial to select the appropriate type of steel and take additional protective measures. For instance, stainless steel pipes offer excellent resistance to corrosion and can handle a wide range of corrosive substances. However, one must carefully consider the specific corrosive properties and concentration levels of the substance being conveyed. In certain cases, applying additional protective coatings or linings may be necessary to prevent corrosion and guarantee the pipes' durability. Regular maintenance and inspection play a vital role in identifying and addressing any signs of corrosion to avoid leaks or failures in the piping system. In conclusion, while steel pipes are suitable for conveying corrosive substances, proper material selection, protective measures, and maintenance are essential for safe and efficient operations.

- Q: How are steel pipes insulated?

- Steel pipes can be insulated using various methods such as applying insulation materials like foam or fiberglass wraps, using thermal tapes, or employing pre-insulated pipe systems where insulation is integrated into the pipe during manufacturing.

- Q: Are steel pipes resistant to earthquakes?

- Steel pipes are generally considered to be more resistant to earthquakes compared to other materials such as concrete or PVC pipes. This is due to the inherent properties of steel, which include its high tensile strength and flexibility. During an earthquake, steel pipes can absorb and distribute the seismic energy more effectively, allowing them to better withstand the shaking and ground movements. Additionally, steel pipes have the ability to deform without rupturing or collapsing, minimizing the risk of structural failure. However, it is important to note that the earthquake resistance of steel pipes ultimately depends on various factors such as the design, installation, and overall structural integrity of the piping system. Proper engineering and construction practices should be followed to ensure the highest level of earthquake resistance for steel pipes.

- Q: What is the lifespan of a steel pipe?

- The lifespan of a steel pipe can vary depending on various factors such as its quality, maintenance, and usage conditions. However, with proper care and maintenance, a well-made steel pipe can last for several decades or even more.

Send your message to us

2''-48'' INCH CARBON STEEL PIPE FITTING TEE CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 300 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords