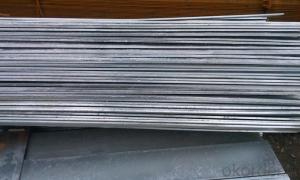

Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Steel Flat with Q195-Q235 for Construction:

Commodity: Hot Rolled Steel Flat Bar

Standard: GB;JIS

Material: Q195-Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Usage/Applications of Carbon Steel Flat with Q195-Q235 for Construction:

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Carbon Steel Flat with Q195-Q235 for Construction:

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Carbon Steel Flat with Q195-Q235 for Construction:

1.Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

2.Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer requests.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel flat bars be coated with anti-slip materials?

- Yes, steel flat bars can be coated with anti-slip materials.

- Q: Can steel flat bars be used for making frames or structures?

- Yes, steel flat bars can indeed be used for making frames or structures. Steel flat bars are versatile and commonly used in construction and manufacturing industries due to their strength and durability. They can be easily welded, cut, and shaped to create various frame or structural components such as beams, columns, braces, and supports. Steel flat bars provide excellent structural stability and are able to withstand heavy loads and impacts, making them suitable for a wide range of applications including buildings, bridges, machinery, and equipment.

- Q: Are steel flat bars suitable for fabrication of industrial machinery?

- Yes, steel flat bars are suitable for the fabrication of industrial machinery. Steel is a highly durable and strong material, making it ideal for constructing heavy-duty machinery that can withstand the demands of industrial applications. The flat bar shape provides structural stability and versatility, allowing for easy fabrication and customization to meet specific design requirements. Additionally, steel flat bars offer excellent resistance to corrosion, which is crucial in industrial environments where machinery may come into contact with moisture or chemicals. Overall, steel flat bars are a reliable and cost-effective choice for fabricating industrial machinery.

- Q: How do steel flat bars perform under impact or shock-loading conditions?

- Steel flat bars generally perform well under impact or shock-loading conditions due to their high strength and resilience. The toughness and ductility of steel allow it to absorb and distribute the energy generated during impact, reducing the risk of deformation or fracture. Additionally, steel's ability to withstand high forces and maintain its structural integrity makes it a reliable choice for applications requiring resistance to impact or shock-loading.

- Q: How do steel flat bars compare to other materials like concrete or glass?

- Steel flat bars have several advantages over other materials like concrete or glass. Firstly, steel flat bars are extremely strong and durable. They have a high tensile strength, which means they can withstand heavy loads and resist deformation. In comparison, concrete is strong in compression but weak in tension, whereas glass is brittle and prone to breaking. Steel flat bars are a much more reliable and long-lasting option when it comes to structural applications. Secondly, steel flat bars offer versatility in terms of design and construction. They can be easily fabricated into various shapes and sizes, making them suitable for a wide range of applications. Concrete, on the other hand, requires complex formwork and curing processes, while glass often has limitations in terms of size and shape. Steel flat bars provide greater flexibility in design and can be easily modified or adjusted if needed. Additionally, steel flat bars have excellent thermal conductivity, which makes them ideal for applications where heat transfer is important. Concrete and glass, on the other hand, have lower thermal conductivity and are not as efficient in transferring heat. This makes steel flat bars a preferred choice for applications such as heat exchangers or structural components in buildings where temperature control is crucial. Moreover, steel flat bars have a higher resistance to fire compared to concrete or glass. They can withstand high temperatures for a longer period without losing their structural integrity. Concrete tends to crack and spall under extreme heat, while glass can shatter or melt. Steel flat bars provide superior fire resistance, making them a safer choice in applications where fire protection is a concern. In conclusion, steel flat bars offer numerous advantages over materials like concrete or glass. They are stronger, more versatile, have better thermal conductivity, and higher resistance to fire. These qualities make steel flat bars a preferred choice for various applications, ranging from structural construction to industrial equipment.

- Q: What are the different surface treatments available for steel flat bars?

- Some of the different surface treatments available for steel flat bars include hot-dip galvanizing, electroplating, painting, powder coating, and sandblasting.

- Q: Can steel flat bars be easily painted or coated?

- Yes, steel flat bars can be easily painted or coated. The smooth and flat surface of steel flat bars allows for easy application of paint or coatings. Prior to painting or coating, it is important to ensure that the surface is clean and free of any rust, dirt, or grease. This can be achieved by sanding the surface and using a suitable cleaner or solvent. Once the surface is properly prepared, a primer may be applied to improve adhesion and durability of the paint or coating. Finally, the desired paint or coating can be applied using a brush, roller, or spray method. It is recommended to follow the manufacturer's instructions for the specific paint or coating being used. Overall, steel flat bars provide a suitable surface for painting or coating and can be easily transformed to meet various aesthetic or protective requirements.

- Q: Lightning protection grounding, what is called three surface welding?

- The grounding position of the grounding body shall not be less than 3m; when the ground is embedded in the garbage or ash, it should be changed and compacted.The grounding body (line) shall be connected by welding, the welding seam should be full and adequate mechanical strength, no slag, undercut, crack, weld, welding defects such as pores, knocking the net after a drug paper, brush asphalt anticorrosive processing.

- Q: What are the advantages of using steel flat bars in construction?

- There are several advantages of using steel flat bars in construction. Firstly, steel flat bars offer exceptional strength and durability. Steel is known for its high tensile strength, which means it can withstand heavy loads and resist bending or breaking under pressure. This makes steel flat bars ideal for structural applications, such as beams, columns, and supports, where strength and stability are crucial. Secondly, steel flat bars are cost-effective. Compared to other building materials, steel is relatively affordable and readily available. Additionally, steel has a long lifespan and requires minimal maintenance, making it a cost-effective choice in the long run. Another advantage of using steel flat bars is their versatility. Steel can be easily manipulated and shaped, allowing for a wide range of design possibilities. Whether it's for creating intricate architectural details or constructing simple frameworks, steel flat bars can be customized to fit various construction needs. Furthermore, steel flat bars have excellent fire resistance properties. Steel is non-combustible and does not contribute to the spread of fire, making it a safe choice for construction in areas where fire protection is a concern. Additionally, steel does not release toxic gases when exposed to high temperatures, further enhancing its safety features. Lastly, steel is an environmentally friendly material. It is highly recyclable, meaning it can be reused or repurposed after its initial use. Recycling steel helps reduce waste and conserve natural resources, making it a sustainable option for construction projects. In conclusion, the advantages of using steel flat bars in construction include their exceptional strength, cost-effectiveness, versatility, fire resistance, and environmental friendliness. These factors contribute to the popularity of steel flat bars in various construction applications.

- Q: Can steel flat bars be used for making marine equipment or structures?

- Yes, steel flat bars can be used for making marine equipment or structures. Steel is a commonly used material in the marine industry due to its strength, durability, and corrosion resistance. Flat bars can be used for various applications such as constructing ship hulls, offshore platforms, or marine equipment like mooring bollards or boat ramps. However, it is important to choose the appropriate grade of steel that meets the specific requirements and standards for marine applications to ensure longevity and safety in harsh marine environments.

Send your message to us

Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords