Hot and Cold Rolled Steel Strip Coils Q195 Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

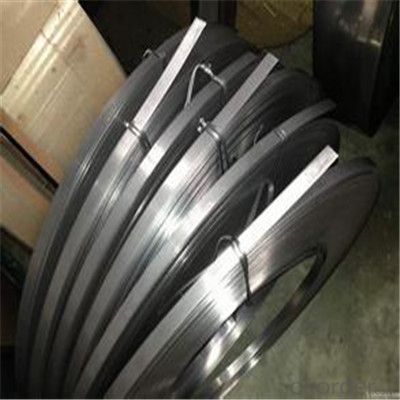

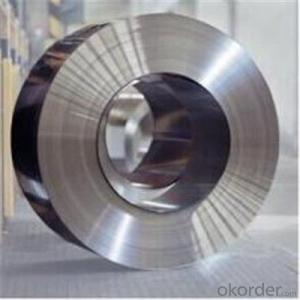

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What are the common edge burr tolerances for steel strips?

- The tolerance levels for edge burrs in steel strips can differ depending on the unique demands of the application and the manufacturing process employed. Generally, the industry norm for edge burr tolerances in steel strips typically ranges from ±0.005 inches to ±0.010 inches. These tolerances guarantee that the edges of the steel strips are free from excessive burrs or sharp edges, which could potentially cause issues during subsequent processing or end-use applications. It is important to acknowledge that the specific tolerances may fluctuate based on factors such as the thickness of the steel strip, the type of steel utilized, and the manufacturing technique employed. Hence, it is crucial to refer to the applicable industry standards or the specific requirements outlined by the customer or end-user to obtain precise edge burr tolerances in steel strips.

- Q: What are the different types of corrosion protection for steel strips?

- Steel strips can be protected from corrosion through various methods. Some commonly used techniques are as follows: 1. Galvanization involves applying a layer of zinc to the steel strip. This zinc layer acts as a sacrificial anode, corroding before the steel does. Galvanization provides excellent corrosion protection and is commonly used for outdoor applications. 2. Powder coating entails applying a powdered polymer onto the steel strip, which is then heated and cured to form a protective coating. This method is highly resistant to corrosion, abrasion, and chemicals, making it popular across industries. 3. Corrosion-resistant paint coatings create a barrier between the steel and the surrounding environment, preventing moisture and oxygen from reaching the metal surface. 4. VCI technology vaporizes a corrosion inhibitor and seals it within a package or enclosure containing the steel strips. This inhibitor forms a protective layer on the metal surface, preventing corrosion. 5. Hot-dip aluminizing involves immersing the steel strip in molten aluminum, which forms a protective layer on the steel surface, providing corrosion resistance. 6. Electroplating immerses the steel strip in an electrolyte solution and passes an electric current through it. This results in the deposition of a layer of metal (such as zinc, nickel, or chromium) onto the steel, offering corrosion protection. 7. Organic coatings, such as epoxy or polyurethane paints, can be applied to provide corrosion protection. These coatings exhibit excellent resistance to moisture, chemicals, and UV radiation. Choosing the most suitable corrosion protection method for steel strips requires careful consideration of the specific application and environment. Each method has its own advantages and limitations, and factors such as durability, cost-effectiveness, and maintenance requirements must be evaluated before making a decision.

- Q: How are steel strips used in the manufacturing of sporting goods?

- Steel strips are commonly used in the manufacturing of sporting goods to provide strength, durability, and reinforcement. These strips are often utilized to create frames, supports, or structural components for various equipment, such as tennis rackets, golf clubs, bicycles, and hockey sticks. Additionally, steel strips can be formed into springs or used as a core material in composite structures, enhancing the performance and reliability of sporting goods.

- Q: How are steel strips processed for improved surface finish?

- Steel strips are processed for improved surface finish through various techniques such as pickling, cold rolling, annealing, and skin passing. Pickling involves removing scale and impurities from the steel surface using acid baths. Cold rolling reduces the thickness and improves the surface smoothness through multiple passes between rollers. Annealing is a heat treatment process that eliminates internal stresses and enhances the surface quality. Skin passing further improves the surface finish by applying light pressure and tension to the steel strip. These processes collectively contribute to achieving a desired surface finish for steel strips.

- Q: Can steel strips be used in magnetic applications?

- Yes, steel strips can be used in magnetic applications. Steel is a ferromagnetic material, meaning it can be magnetized and exhibit magnetic properties. Steel strips can be used in various magnetic applications such as magnetic storage devices, transformers, motors, and sensors.

- Q: What are the main factors affecting the electrical conductivity of steel strips?

- The main factors affecting the electrical conductivity of steel strips are the composition of the steel, impurities present in the material, temperature, and the presence of any surface coatings or oxide layers.

- Q: How do steel strips contribute to reducing maintenance costs in various applications?

- Steel strips contribute to reducing maintenance costs in various applications in a number of ways. Firstly, steel strips are known for their durability and strength, which makes them highly resistant to wear and tear. This means that they can withstand heavy loads and harsh environmental conditions without deteriorating quickly. As a result, the need for frequent repairs and replacements is significantly reduced, leading to lower maintenance costs. Additionally, steel strips have excellent corrosion resistance properties. They can withstand exposure to moisture, chemicals, and other corrosive substances, which are common in many applications. By preventing corrosion and rusting, steel strips help to extend the lifespan of the equipment or infrastructure, reducing the frequency of maintenance interventions and associated costs. Moreover, steel strips can be easily fabricated into various shapes and sizes, making them highly versatile for different applications. This flexibility allows for precise customization and ensures a perfect fit, minimizing the risk of malfunctions and the need for maintenance due to poor fitting or alignment. Furthermore, steel strips provide good thermal conductivity, which is crucial in applications where temperature variations occur. The ability to efficiently transfer heat helps to prevent overheating or freezing, reducing the likelihood of damage and the need for maintenance or repairs. Lastly, steel strips are often treated with protective coatings or finishes, such as galvanization, which further enhances their resistance to corrosion and wear. These coatings act as a barrier, protecting the underlying steel from environmental elements and extending its lifespan. In conclusion, steel strips contribute to reducing maintenance costs in various applications by offering durability, corrosion resistance, versatility, thermal conductivity, and protective coatings. By minimizing the frequency of repairs, replacements, and maintenance interventions, steel strips help to optimize operational efficiency and reduce overall expenses.

- Q: How are steel strips supplied to customers?

- Steel strips are typically supplied to customers through various methods. One common method is through steel service centers or steel distributors. These centers or distributors procure steel strips directly from steel mills or manufacturers in large quantities and then process and distribute them to customers based on their specific requirements. The steel strips are usually supplied in coils, which are rolled up and tightly wound. These coils can vary in size and weight depending on the customer's needs. The coils are then stored in warehouses or storage facilities until they are ordered by customers. When a customer places an order, the steel service center or distributor will retrieve the required coil from their inventory. Depending on the customer's preference and logistical requirements, the steel strips can be supplied in various forms. They can be cut to specific lengths, slit into narrower strips, or leveled and flattened to ensure uniformity and precision. The steel strips are then packaged securely to protect them during transportation. Depending on the size and weight of the coils, they may be shipped via truck, rail, or even by sea for international customers. The coils are usually stacked and secured on pallets or loaded directly onto flatbed trucks or shipping containers. In addition to steel service centers, some manufacturers may also supply steel strips directly to their customers. This is more common for large-scale projects or when customers have specific requirements that can be better met by directly working with the manufacturer. Overall, the supply of steel strips to customers involves a well-coordinated process between steel mills, service centers or distributors, and transportation logistics to ensure timely and efficient delivery of the steel strips to the customers.

- Q: Are steel strips suitable for making electrical connectors?

- Without a doubt, steel strips are a suitable option for fabricating electrical connectors. These strips possess numerous advantages that have contributed to their widespread popularity in the realm of electrical connectors. First and foremost, steel serves as an exceptionally conductive material, thereby ensuring the efficient transmission of electrical currents. This quality makes steel strips the perfect conduit for electrical signals, guaranteeing a secure and steadfast connection. Moreover, steel boasts impressive strength and durability, which greatly enhance the longevity and reliability of electrical connectors. Steel strips can withstand even the harshest environmental conditions, including extreme temperatures, moisture, and corrosion, thus ensuring the continued functionality and safety of the connectors in a variety of circumstances. Furthermore, steel strips can be easily molded and fashioned into a plethora of connector designs, allowing for unparalleled versatility and customization. This adaptability enables the creation of connectors that are tailored to specific electrical applications and requirements. Additionally, steel strips present a cost-effective alternative compared to other materials utilized in electrical connectors, making them an astute choice for manufacturers and end-users alike. In conclusion, the qualities of excellent conductivity, durability, adaptability, and cost-effectiveness render steel strips a truly fitting option for the production of electrical connectors.

- Q: Can steel strips be used for making automotive components?

- Yes, steel strips can be used for making automotive components. Steel strips are often used in the automotive industry for various applications such as manufacturing chassis, body panels, reinforcement parts, and structural components. The high strength and durability of steel make it an ideal material for automotive applications, providing the necessary strength and safety required for automotive components. Additionally, steel strips can be easily formed and fabricated to meet the specific design requirements of automotive parts.

Send your message to us

Hot and Cold Rolled Steel Strip Coils Q195 Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords