Calcined Petroleum Coke as Injection Coke for Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.4

- Supply Capability:

- 1014 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

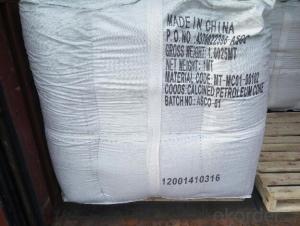

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: What is the starting temperature and final forging temperature of carbon steel?

- The forging temperature range should be as wide as possible, to reduce forging times, improve productivity.1. initial forging temperatureInitial forging temperature is blank began forging temperature should be understood as the highest heating temperature allows steel or alloy in the heating furnace. The furnace before removing from the blank to the forging equipment to forging blank, blank size according to the delivery method and heating furnace and forging a distance between the equipment, there are a few blank tens of degrees of temperature drop. Therefore, really began forging a low temperature, the initial forging blank before, should try to reduce the temperature drop.

- Q: How do forests act as carbon sinks?

- Forests act as carbon sinks by absorbing carbon dioxide from the atmosphere through the process of photosynthesis. Trees and other plants take in carbon dioxide and convert it into oxygen, while storing the carbon in their trunks, branches, and roots. This stored carbon remains in the forest ecosystem, reducing the amount of greenhouse gases in the atmosphere and helping to mitigate climate change.

- Q: How is carbon used in the production of pharmaceuticals?

- Carbon is used in various ways in the production of pharmaceuticals. One primary use of carbon is in the synthesis of organic compounds, which form the basis of many drugs. Carbon atoms are the building blocks of organic compounds, and they are essential for creating the complex structures found in pharmaceutical molecules. Carbon is also used in the production of active pharmaceutical ingredients (APIs). APIs are the components of a drug that provide the desired therapeutic effect. Carbon is often incorporated into the structure of APIs to enhance their stability, bioavailability, and efficacy. Carbon-based molecules can be modified to fine-tune their properties, making them more effective in targeting specific diseases or conditions. Moreover, carbon is utilized in the purification and separation processes during pharmaceutical production. Carbon-based adsorbents, such as activated carbon, are commonly used to remove impurities and contaminants from drug formulations. These adsorbents have a high surface area and can effectively bind to and remove unwanted substances, ensuring the purity and safety of pharmaceutical products. Carbon is also employed in the development of drug delivery systems. Carbon nanomaterials, such as carbon nanotubes and graphene, have unique properties that make them suitable for drug delivery applications. These nanomaterials can encapsulate drugs, allowing for controlled release and targeted delivery to specific tissues or cells. They can also improve the solubility and stability of drugs, enhancing their therapeutic potential. In summary, carbon plays a crucial role in the production of pharmaceuticals. It is involved in the synthesis of organic compounds, the creation of active pharmaceutical ingredients, the purification of drugs, and the development of drug delivery systems. Its versatility and ability to form complex structures make carbon an essential element in the pharmaceutical industry.

- Q: What are the consequences of increased carbon emissions on vulnerable communities?

- Vulnerable communities bear the brunt of severe consequences caused by the increase in carbon emissions. To begin with, these communities lack the necessary resources and infrastructure to adapt to and alleviate the impacts of climate change. The contribution of carbon emissions to global warming makes it more likely for these communities to experience extreme weather events, such as hurricanes, floods, and heatwaves. Consequently, displacement, loss of homes, and even loss of lives disproportionately affect those who are already marginalized. Moreover, the rise in carbon emissions leads to air pollution, which poses significant health risks to vulnerable communities. Inhabitants of low-income areas often reside in close proximity to industrial plants or highways with high emission levels, increasing their vulnerability to respiratory diseases, cardiovascular problems, and other health issues. This is particularly true for children, the elderly, and individuals with pre-existing health conditions. The consequences of increased carbon emissions also extend to food security. Climate change disrupts agriculture and alters the timing of growing seasons, resulting in reduced crop yields and food shortages. Vulnerable communities heavily dependent on subsistence farming or residing in areas prone to droughts or floods are at risk of malnutrition and hunger. This further aggravates existing inequalities and can lead to social unrest and economic instability. Furthermore, vulnerable communities often rely on natural resources, such as fishing, forestry, or tourism, for their livelihoods. The negative impacts of carbon emissions, such as ocean acidification and coral bleaching, jeopardize these industries, leading to job losses and economic decline. This perpetuates the cycle of poverty and socio-economic vulnerability. In conclusion, increased carbon emissions disproportionately harm vulnerable communities by exacerbating existing inequalities and intensifying the challenges they face. It is crucial to address these consequences through climate mitigation efforts, adaptation strategies, and support for sustainable development.

- Q: How does carbon affect the formation of haze?

- Carbon plays a significant role in the formation of haze as it is a major component of particulate matter, especially in the form of black carbon or soot. When released into the atmosphere through incomplete combustion processes, carbon particles can contribute to the formation of haze by scattering and absorbing sunlight. This leads to reduced visibility and the formation of a fog-like, hazy appearance in the air. Additionally, carbon particles can act as nuclei for the condensation of water vapor, further enhancing haze formation and the persistence of foggy conditions.

- Q: What are the advantages of carbon nanotube transistors?

- Carbon nanotube transistors offer several advantages compared to traditional silicon-based transistors. Firstly, carbon nanotubes have excellent electrical properties. They possess high electron mobility, which means that electrons can move through them quickly and easily. This allows for faster switching speeds and higher operating frequencies, making them ideal for high-performance applications such as computers and communication devices. Secondly, carbon nanotubes have a very small size. They can be as small as a few nanometers in diameter, which is several orders of magnitude smaller than the feature sizes of silicon transistors. This miniaturization potential enables the development of highly compact and densely packed electronic circuits, leading to higher integration levels and increased device functionality. Additionally, carbon nanotubes are more resistant to heat and have better thermal conductivity than silicon. This means that they can handle higher temperatures without degrading, allowing for more efficient operation and reducing the need for complex cooling systems. It also enables the fabrication of devices that can withstand harsh environments, making them suitable for applications in aerospace, automotive, and defense industries. Furthermore, carbon nanotubes are mechanically strong and flexible. They can be bent and stretched without breaking, making them suitable for use in flexible electronics and wearable devices. Their mechanical robustness also ensures long-term stability and reliability, leading to improved device performance and longevity. Lastly, carbon nanotube transistors can be fabricated using existing manufacturing processes, making them compatible with current semiconductor technologies. This means that they can be integrated into existing electronic systems without significant modifications, reducing the cost and time required for their implementation. Overall, the advantages of carbon nanotube transistors, including their high electrical performance, small size, thermal stability, mechanical strength, and compatibility with existing manufacturing processes, make them a promising alternative to traditional silicon transistors for future electronic applications.

- Q: How does carbon impact ocean acidity?

- Carbon impacts ocean acidity through a process called ocean acidification. When carbon dioxide (CO2) from the atmosphere is absorbed by seawater, it reacts with water molecules to form carbonic acid. This acidification process lowers the pH levels of the ocean, making it more acidic. The primary source of carbon dioxide in the atmosphere is human activities such as burning fossil fuels, deforestation, and industrial processes. As the concentration of CO2 increases in the atmosphere due to these activities, more and more of it is absorbed by the oceans. The increase in acidity has several detrimental effects on marine life. Many organisms that have calcium carbonate shells, such as coral reefs, shellfish, and some plankton species, are particularly vulnerable to ocean acidification. The increased acidity makes it harder for these organisms to build and maintain their shells, leading to reduced growth rates and increased mortality. Ocean acidification also affects the entire marine food web. It disrupts the balance between predators and prey, as some species of plankton are less able to develop and survive in acidic conditions. This can have cascading effects on the entire ecosystem, impacting fish populations, marine mammals, and ultimately even humans who rely on seafood for sustenance. Additionally, ocean acidification can have significant economic impacts. Commercial fisheries and tourism industries that depend on healthy marine ecosystems can suffer due to the decline in fish populations and the degradation of coral reefs. To mitigate the impacts of carbon on ocean acidity, it is crucial to reduce carbon dioxide emissions and transition to cleaner and more sustainable energy sources. Taking steps to protect and restore marine ecosystems, such as creating marine protected areas and implementing sustainable fishing practices, can also help to mitigate the effects of ocean acidification.

- Q: What is the carbon footprint?

- The carbon footprint is a measure of the total greenhouse gases, specifically carbon dioxide (CO2), that are released into the atmosphere due to human activities. It quantifies the impact individuals, organizations, or countries have on the environment by contributing to climate change. This impact encompasses both direct emissions from burning fossil fuels for transportation, heating, and electricity, as well as indirect emissions from the production and transportation of goods and services we consume. Measured in units of carbon dioxide equivalent (CO2e), the carbon footprint serves as a vital tool for assessing and managing our environmental influence. By comprehending and diminishing our carbon footprint, we can alleviate climate change and strive for a more sustainable future.

- Q: What role does carbon play in the carbon cycle?

- Carbon plays a crucial role in the carbon cycle as it is the key element that cycles through various reservoirs on Earth. It is present in both organic and inorganic forms and moves between the atmosphere, oceans, land, and living organisms. The carbon cycle is a complex process that involves several interconnected processes, including photosynthesis, respiration, decomposition, and combustion. In the atmosphere, carbon exists primarily as carbon dioxide (CO2) gas, which is essential for photosynthesis. Green plants and algae absorb CO2 during photosynthesis, converting it into organic compounds such as glucose and releasing oxygen as a byproduct. This process helps to regulate the amount of carbon dioxide in the atmosphere and provides the foundation for the food chain. Through respiration, living organisms break down organic compounds to release energy, producing carbon dioxide as a waste product. This carbon dioxide can be immediately reused by plants during photosynthesis, completing the cycle. Additionally, when organisms die, their remains are broken down by decomposers, such as bacteria and fungi, which release carbon dioxide back into the atmosphere. The carbon cycle also involves the transfer of carbon to and from the oceans. Carbon dioxide dissolves in seawater, where it can be taken up by marine organisms, such as phytoplankton and corals, during photosynthesis. Over time, the remains of these organisms sink to the ocean floor and can become locked away in sediments, forming fossil fuels like coal, oil, and natural gas. Through geological processes, these fossil fuels can be released back into the atmosphere when burned, contributing to increased carbon dioxide levels. Human activities, particularly the burning of fossil fuels and deforestation, have significantly impacted the carbon cycle. Excessive carbon dioxide emissions from these activities have led to an imbalance in the cycle, causing an increase in atmospheric carbon dioxide concentrations and contributing to global climate change. Overall, carbon plays a critical role in the carbon cycle as it is the fundamental building block of life and the key element that cycles through various reservoirs, regulating Earth's climate and sustaining life on our planet.

- Q: How to test aldehyde group and carbon carbon double bond in acrolein

- Can be oxidized into carboxyl aldehyde with silver ammonia solution or new copper hydroxide, then the bromine test double bonds, because the aldehyde will affect the bond detection, and will not affect the detection of double bond of carboxyl.

Send your message to us

Calcined Petroleum Coke as Injection Coke for Foundry Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.4

- Supply Capability:

- 1014 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords