Fiberglass Mat Tissue C Glass Woven Roving for FRP Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 m²

- Supply Capability:

- 17600kg Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

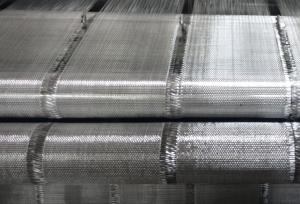

Glass woven rovings are bidirectional fabric made by direct rovings in plain weave pattern.

Compatible with unsaturated polyester,vinylresin ,epoxy resin.

Applicable for hand lay-up, winding and compress molding process,Suitable for manufacturing tank,boat,automobile parts and other FRP products.

Consistent thickness and excellent surface treatment.

Rapid impregnating and good compatibility with resin.

Uniform tension,high dimensional stability and making handing easy.

Good mechanical properties and high strength of parts.

Technical Data Sheet

Style | Yarn(Tex) | Density(ends/10cm) | (g/m2) | Width(cm) | Tensile strength(N/50mm) | ||

Warp | Weft | Warp | Weft | ||||

EWR200 | 200 | 50 | 50 | 200±16 | 90/100 | ≥1300 | ≥1100 |

ERW400 | 600 | 35 | 32 | 400±32 | 100/127 | ≥2500 | ≥2200 |

EWR570 | 1150 | 26 | 24 | 570±45 | 100/127 | ≥3600 | ≥3300 |

EWR600 | 1200 | 26 | 24 | 600±48 | 100/127 | ≥4000 | ≥3850 |

EWR800 | 2400 | 18 | 16 | 800±64 | 100/127 | ≥4600 | ≥4400 |

CWR135 | 150 | 50 | 40 | 135±10 | 90/100 | ≥750 | ≥600 |

CWR180 | 200 | 50 | 50 | 200±16 | 90/100 | ≥1150 | ≥1000 |

CWR290 | 450 | 35 | 30 | 290±22 | 90/100 | ≥1500 | ≥1400 |

CWR310 | 500 | 35 | 28 | 310±24 | 90/100 | ≥1600 | ≥1500 |

CWR330 | 500 | 35 | 31 | 3300±26 | 90/100 | ≥1700 | ≥1600 |

CWR350 | 500 | 35 | 35 | 350±28 | 90/100 | ≥1800 | ≥1700 |

CWR400 | 500 | 40 | 40 | 400±32 | 90/100 | ≥2000 | ≥1900 |

CWR600 | 1200 | 26 | 24 | 600±48 | 100/127 | ≥2750 | ≥2600 |

CWR800 | 2400 | 18 | 16 | 800±61 | 100/127 | ≥3000 | ≥2900 |

FAQ

Package and Storage:Eech roll is packed by polyester bag,and then put into a cardboard box or plastic wowen bag.The weight of each roll is between 20 to 85 Kg, The rolls are to be horizontally placed and could be in bulk or on pallet.Optimum storage conditions are between the temperature of 5~35℃ and with the humidity between 35%~65%.The product should be used within 12 months from the time of delivery and remain in theiroriginal packaging until just prior to use.

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The roll diameter of fiberglass mat tissue can have a significant impact on its handling. A larger roll diameter generally means a heavier and bulkier roll, making it more challenging to handle and maneuver. This can be particularly important in situations where the fiberglass mat tissue needs to be transported or installed manually. A larger roll diameter may also require more physical effort to lift and move, which can lead to increased strain on the individuals handling it. Moreover, larger roll diameters can also take up more space, making storage and transportation more cumbersome. On the other hand, a smaller roll diameter can make the fiberglass mat tissue easier to handle, as it is lighter and more compact. This can be particularly advantageous in situations where frequent movement and installation are required, such as in construction sites or manufacturing facilities. Additionally, a smaller roll diameter may allow for more efficient storage and transportation, as it takes up less space and can be stacked more easily. This can help optimize logistics and minimize costs associated with storage and transportation. Overall, the roll diameter of fiberglass mat tissue directly affects its handling characteristics, with larger diameters making it more challenging to handle and smaller diameters providing easier handling and improved storage efficiency.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue, as an insulation material, offers numerous advantages over its counterparts. Primarily, it possesses exceptional thermal insulation properties, effectively preventing the transfer of heat and maintaining indoor temperatures at a comfortable level. This quality is particularly significant in extreme climates, where the building envelope may be susceptible to extreme cold or heat. Furthermore, fiberglass mat tissue exhibits resistance to moisture, mold, and mildew, which contributes to its longevity and durability as an insulation option. Its inability to absorb water prevents the growth of mold and the deterioration of the material over time. This attribute proves especially advantageous in areas with high humidity or a propensity for moisture accumulation, such as basements or bathrooms. In addition, fiberglass mat tissue is non-combustible and possesses a high fire resistance rating. Consequently, it serves as a safe choice for insulation, limiting the spread of flames in the event of a fire. It also acts as a barrier, impeding the fire from extending to other sections of the building and granting occupants valuable time for evacuation. Regarding installation, fiberglass mat tissue is relatively easy to handle and install. It can be conveniently cut to fit any desired shape or size, allowing for flexibility during the installation process. Its versatility is further evident in its applicability to walls, floors, ceilings, and roofs. Lastly, fiberglass mat tissue stands as an environmentally friendly option. It is manufactured from recycled glass and sand, reducing waste and conserving precious natural resources. Moreover, it remains recyclable at the conclusion of its lifespan, further minimizing its environmental impact. Overall, the exceptional thermal insulation properties, durability, moisture and fire resistance, ease of installation, and environmental sustainability of fiberglass mat tissue position it as a highly favorable choice in comparison to alternative insulation materials.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Yes, fiberglass mat tissue is resistant to alkalis.

- Q: Can fiberglass mat tissue be used for swimming pool construction?

- Certainly, fiberglass mat tissue is suitable for the construction of swimming pools. This versatile material is widely utilized in the construction sector due to its robustness, durability, and ability to withstand water and chemicals. Its primary purpose is to reinforce the swimming pool shells, thereby enhancing their structural integrity and preventing any potential issues like cracking or leakage. Moreover, fiberglass mat tissue is renowned for being lightweight and easy to manipulate, which contributes to its popularity among pool builders. Nonetheless, it is crucial to ensure that the fiberglass mat tissue employed in swimming pool construction adheres to the required standards and regulations in order to guarantee the pool's safety and longevity.

- Q: What is the tear strength of fiberglass mat tissue?

- The tear strength of fiberglass mat tissue refers to the ability of the material to resist the propagation of tears or cracks when subjected to external forces. It is a crucial characteristic that determines the durability and performance of fiberglass mat tissue in various applications. The tear strength of fiberglass mat tissue is typically measured using standardized testing methods, such as the ASTM D1922 tear resistance test. This test involves subjecting a sample of the material to a controlled force, typically in the form of a tensile load, and measuring the force required to cause a tear or rupture. The tear strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, the quality of the raw materials used, and the specific application requirements. Generally, fiberglass mat tissues are designed to have high tear strength to withstand the stresses and strains encountered during installation and use. Fiberglass mat tissue is commonly used in industries such as construction, automotive, aerospace, and marine, where its high tear strength and other desirable properties make it an ideal choice. It is often utilized as a reinforcement material in composites, providing added strength and durability to the final product. In conclusion, the tear strength of fiberglass mat tissue is an important property that determines its resistance to tearing or cracking under applied forces. By ensuring a high tear strength, fiberglass mat tissue can withstand the demands of various applications and provide long-lasting performance.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Yes, fiberglass mat tissue can be used for insulation in pharmaceutical storage areas. Fiberglass mat tissue is a versatile material that offers excellent thermal insulation properties. It is often used in various industries, including pharmaceuticals, due to its ability to regulate temperature and provide insulation against heat transfer. In pharmaceutical storage areas, maintaining the appropriate temperature is crucial to ensure the integrity and stability of stored medications and vaccines. Fiberglass mat tissue can help create a temperature-controlled environment by reducing heat transfer between different areas and protecting the stored products from external temperature fluctuations. Additionally, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it suitable for pharmaceutical storage areas where cleanliness and hygiene are essential. It can be easily placed between walls, ceilings, and floors to provide a barrier against heat flow, thus maintaining the desired temperature inside the storage area. Moreover, fiberglass mat tissue is a non-combustible material, which adds an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, ensuring the protection of valuable pharmaceutical products and reducing the risk of fire-related accidents. Overall, fiberglass mat tissue is an effective choice for insulation in pharmaceutical storage areas, providing thermal regulation, moisture resistance, cleanliness, and fire safety. It helps maintain the required temperature and ensures the integrity and stability of stored medications and vaccines.

- Q: Does fiberglass mat tissue require any special precautions during disposal?

- Yes, fiberglass mat tissue requires special precautions during disposal. It should be handled with care and disposed of in accordance with local regulations. Due to its composition, fiberglass mat tissue can release harmful fibers when disturbed, which can be a health hazard if inhaled. Therefore, it is important to wear protective clothing, gloves, and a mask when handling and disposing of fiberglass mat tissue. Additionally, it should be sealed in a plastic bag or container to prevent the release of fibers into the environment.

- Q: What are the potential environmental impacts of using fiberglass mat tissue?

- The potential environmental impacts of using fiberglass mat tissue can vary depending on several factors. One potential impact is the extraction and production of the raw materials needed to manufacture fiberglass. The process of obtaining glass fibers involves mining and processing silica sand, which can lead to habitat destruction, soil erosion, and water pollution. Additionally, the production of glass fibers requires a significant amount of energy, which often comes from non-renewable fossil fuels, contributing to greenhouse gas emissions and climate change. Another environmental impact of using fiberglass mat tissue is the release of hazardous chemicals during the manufacturing process. Fiberglass production involves the use of resins, binders, and other chemicals that can be harmful to human health and the environment. These chemicals may be released into the air, water, or soil, potentially contaminating nearby ecosystems and posing a risk to wildlife and human populations. Furthermore, the disposal of fiberglass mat tissue at the end of its life cycle can also have environmental implications. Fiberglass is not easily biodegradable, and proper disposal methods are crucial to prevent it from ending up in landfills or being incinerated, both of which can release harmful substances into the environment. Recycling fiberglass can be challenging due to its complex composition, leading to a significant portion of it being discarded improperly. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction materials, can contribute to energy consumption and greenhouse gas emissions. For example, fiberglass insulation can require additional energy for manufacturing, transportation, and installation compared to alternative insulation materials like cellulose or mineral wool. In conclusion, the potential environmental impacts of using fiberglass mat tissue are diverse and range from habitat destruction and pollution during raw material extraction to the release of hazardous chemicals during manufacturing and difficulties in disposal and recycling. It is essential for manufacturers and consumers to consider these impacts and explore alternative materials and production processes that minimize harm to the environment.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- There are several different manufacturing processes for fiberglass mat tissue, including wet-laid process, dry-laid process, and spunbonding process. The wet-laid process involves blending fiberglass fibers with a water-based binder, forming a mat, and then drying it. The dry-laid process, on the other hand, uses air to disperse the fibers onto a moving conveyor belt, which are then bonded together using heat and pressure. The spunbonding process involves extruding molten fiberglass polymer through fine nozzles, which solidifies into continuous filaments that are then collected onto a conveyor belt to form a mat.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- Fiberglass mat tissue performs exceptionally well in terms of dimensional stability. Due to its unique composition and manufacturing process, fiberglass mat tissue exhibits minimal shrinkage or expansion when exposed to temperature variations or moisture. This characteristic makes it an ideal material for various applications where dimensional stability is crucial, such as in the construction industry for reinforcing walls, roofs, or floors. The consistent size and shape of fiberglass mat tissue ensure that it maintains its original dimensions over time, providing long-term durability and reliability. Additionally, its dimensional stability allows for precise cutting, shaping, and installation, reducing waste and increasing efficiency in manufacturing processes. Overall, fiberglass mat tissue offers excellent dimensional stability, making it a favored choice in industries where accurate and stable dimensions are vital.

Send your message to us

Fiberglass Mat Tissue C Glass Woven Roving for FRP Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 m²

- Supply Capability:

- 17600kg Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords