Butterfly Valve Ductile Iron Cast Iron High Quality Can be Customised

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:The products are widely used in industries such as water projects, urban water supply & drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding,medicine and metallurgy. Equipment used in regulating or cutting off medium in pipeline.

2.Main Features of the Manual Wafer Butterfly Valve

1)Small in size and light in weight and maintaince. It can be mounted whereever needed.

2)Simple, compact structure, quick 90 degree on-off operation.

3)Disc has two-way bearing, perfect seal, without leakage under the pressure test.

4)Flow curve tending to straight-line. Excellent regulation performance.

5)Various kinds of materials, applicable to different medium.

6)Strong wash and brush resistance and can fit to bad working condition.

7)Center plate structure, small torque of open and close.

8)Long service life. Standing the test of ten thousands opening and closing operation.

9)Can be used in cutting off and regulation medium.

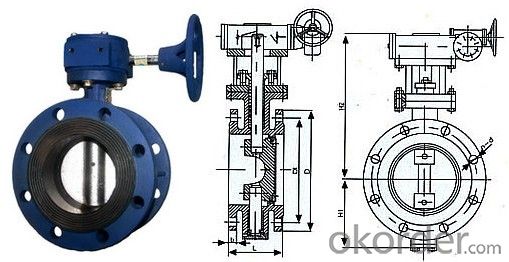

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

Size: DN40-DN1400

Material:body-CI/DI/WCB/SS

disc:DI/CF8/CF8M/C95400

Professional Maufacturer for more than 10 yearsSize Range 1"~6"

Maximum operating preeure 10bar (at 20°C)

Recommended working pressure 6bar (at 20°C)

General temperature range -10°C~+95°C

Standard type ISO2037/BS4825-1/AS1528-1

End connections butt weld (standard) for inch tubing (O.D.tubes)

STAINLESS STEEL HYGIENIC BUTTERFLY VALVE

sanitary butterfly valve

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Butterfly valve use

- On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve is fully open to fully closed is usually less than 90 degrees, butterfly and butterfly stroke itself has no self-locking capability, in order to position the disc to install the valve stem on the worm gear.

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- High performance materials have a lot of outstanding advantages: such as low water absorption, corrosion resistance, insulation, cold insulation performance, etc., is 4 times the ordinary material butterfly valve.Anti condensation butterfly valve body adopts ultra light aluminum alloy valve body, its weight is only 1/3 of the traditional butterfly valve, the torque is small, the use and installation is convenient, and the corrosion is avoided.

- Q: Water supply pipe gate valve and butterfly valve which good?

- Butterfly valve is relatively applicable1 electric butterfly valve 0-90 degree rotation angle stroke valve, specific flow characteristics, small size, high performance price ratio2, electric valve up and down movement of the straight stroke control method, can be used as shut-off valve, large size, expensive3, electric butterfly valve can not be used for high temperature and high pressure conditions, not wear-resistant. Electric gate valve is generally used to close the material with a grain of material, suitable for high temperature and high pressure conditionsOur company specializes in the production of various types of valves, there is a need to help me, I would like to help

- Q: Can the inlet and outlet of butterfly valve be reversed? Why? What will happen if the reverse gear is installed?

- Hard seal butterfly valve in any case, the reverse loading will cause tight seal.

- Q: How does the pneumatic butterfly valve control the angle of opening?

- The angle of the rotating shaft is controlled so that the angle of the butterfly valve is controlled. You just have a good electrical locator

- Q: How to calculate the size of the manual butterfly valve?

- 1. The size of the installation fits only two: the length of the structure and the distance between the flanges.2, butterfly (Manual butterfly) butterfly plate installed in the pipe diameter direction. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is 0 degrees -90 degrees between, when rotates to 90 degrees, the valve opens the card completely. Butterfly valve structure is simple, small size, light weight, only by a few parts. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the butterfly plate thickness is the only resistance when the medium passes through the valve body, so the pressure drop produced by the valve is very small, so the flow control characteristic is better. Butterfly valve has an elastic seal and metal seal, two types of seals. Resilient sealing valve. The sealing ring can be mounted on the valve body or attached to the periphery of the disc.

- Q: How does PLC control butterfly valves?

- PLC control butterfly valve, usually control pneumatic butterfly valve or electric butterfly valve, see which way you control butterfly valve.PLC control pneumatic butterfly valve, that is, PLC program control, electric control, gas control, gas control butterfly valve;PLC control electric butterfly valve, that is, PLC program control electric, electric control butterfly valve.Ordinary switch butterfly valve is the program control on and off, to the 1 way valve open, to another 1 way valve off.

- Q: What is the meaning of American Standard butterfly valve B series

- American Standard flange connection is divided into A, B series. A series for normal flanges, B series for compact flanges. 24 "to no AB series, flange standards for B16.5, 24" above B16.47.

- Q: Butterfly valve, two-way pressure and one-way pressure what is the difference?

- One way sealing butterfly valve is the front of the butterfly valve. When it closes, it must face the direction of the medium. The medium flows only in one direction, and the arrow on the valve body indicates the direction of the flow direction of the medium. Attention should be paid to the flow direction of the medium during installation. Two way butterfly valve is butterfly plate can face or back to the media flow direction, installation without attention to medium flow direction, in the valve body also does not indicate the direction of the medium flow arrow. Two way sealing butterfly valve stem force is greater than one-way butterfly valve stem. Design, the same diameter, pressure butterfly valve, two-way sealing butterfly valve rod diameter than one-way sealing butterfly valve stem diameter.

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- If it only puffs blue smoke when you start it and then burns off after a second then its the valve stem seals that need to be replaced which is common on 350 and 305 engine prior to 1990 and have over 150,000 miles or so. The Chilton repair manual explains the procedure on how to replace these.Now if it smokes all the time then it could be caused by worn out rings on your pistons .

Send your message to us

Butterfly Valve Ductile Iron Cast Iron High Quality Can be Customised

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords