Butterfly Valve DN80 BS5163 Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

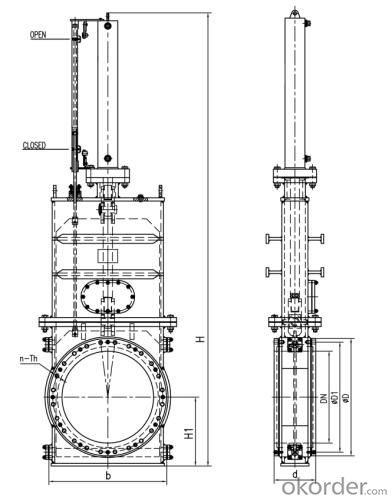

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What's the difference between the three eccentric butterfly valve and the two eccentric butterfly valve?

- Double eccentric butterfly valve refers to: valve plate and central axis partial, simply said that there are two parts of the butterfly valve.Three eccentric butterfly valve, there are three places are biased

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: What's the size of the signal butterfly valve sleeve?

- The structure characteristics and working principle: the top design electrical device the butterfly valve of the worm and the worm gear driving device, and with the stem straight connecting transmission. In the closed precision electromechanical device, opening mechanical instructions and imported electrical components and parts with rust proof valve.

- Q: Butterfly valve common faults and treatment methods?

- Three, summary:Only familiar with every detail of circulating water pump outlet valve and butterfly valve equipment, timely and thorough maintenance and strict debugging, to ensure the safety and reliability of equipment operation, to ensure the healthy and orderly operation of equipment.

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- Anti condensation butterfly valve principle: the use of the high performance plate material, can effectively prevent the temperature of body parts, isolating the transfer medium in the pipeline, to the actuator and the connecting flange surface without dew.

- Q: How much is the Honeywell butterfly DN300?

- Find the agent or find a reliable valve plant a lot of foreign brands are in Chinese OEM so find a reliable factory is relatively good service to keep up

- Q: What's the difference between D71X-16 and D71H-16 butterfly valves?

- D71X-16 and D71H-16 butterfly difference is that the cut-off is not the same, the latter is stainless steel seal, corrosion resistance, friction, acid or impurities can be medium fluid. The former is rubber sealed, only through the general temperature of the medium, not acid, with more, you can ask Luoyang crown Ning

- Q: I have 1993 Seville 4.9. I got a new EGR valve but it didn't help. I tested it with vacuum pump, it won't hold pressure at all, same with old one. Is that new EGR valve bad or just different type of EGR that vacuum pump won't work? Thanks!

- Did you get that EGR valve from Cadillac dealership?? A lot of those aftermarket parts DO NOT LIKE Cadillac's!!!!!!!!!! I run into that all the time nor will we use any aftermarket parts due to the problems we have with them. Make sure that switch is working that controls the EGR valve. I have seen those fail also. You need access to a serive manual so you can command that switch on off check with a test light a vacuum gauge to make sure you are getting vacuum to that EGR Valve. Also, make sure that the ports are not clogged up with carbon, even check the pipe inside the throttle body opening, they should be clean inside those tubes !!!!!!!!!

- Q: i was changing valve seals and two dropped i can see the head of the valve but a magnet wont pull them up i put air the spark plug hole too but no luck 1985 ford bronco II

- The valve head is larger then the valve port, so it's not coming out of there. Pull the head.

- Q: The difference between vertical and horizontal butterfly valves in municipal water supply

- Function is no difference, mainly the installation conditions are not the same, vertical valve shaft in the vertical direction, the valve well on the deep, horizontal valve shaft in the horizontal direction, the valve width to be larger, and the other is no difference

Send your message to us

Butterfly Valve DN80 BS5163 Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords