High Quality Flanged Wafer Type Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Flanged Wafer Type Butterfly Valve

Product Information Of High Quality Flanged Wafer Type Butterfly Valve:

Butterfly valve is mainly consisted of body, stem, disc, seat and driver (lever, gearbox, pneumatic and electric Actuator) and so on. On off and controlling flow of valve are made by turning stem and disc together.

Size | DN40-DN1200 |

End flange | ANSI B 16.1, EN 1092, AS 2129 |

Face to face | ANSI B 16.10; EN 558-1 Series 20 |

Top flange | ISO 5211 |

Normal Pressure | DN40-DN600 PN1.0/1.6MPa (150/200PSI) DN700-DN1200 PN1.0MPa (150PSI) |

Body | CI/DI/WCB/ALB/CF8/CF8M |

Disc | DI/ALB/Rubber lined Disc/ 1.2501/CF8M/1.4529/CF8/Hastelloy Alloy/Monel |

Stem: | 416/304/316/431/17-4PH |

Seat | NR/Hypalon/EPDM/Neoprene/NBR/Wear-Resistant EPDM/Viton/Silicon/Heat-Resistant EPDM/White NBR/White EPDM/EPDM (NSF)/PTFE |

Suitable Temperature | -40c~80c |

Apply | Fresh water, sewage, sea water, air, vapor, food, medicine, oils, alkalis, salt etc. |

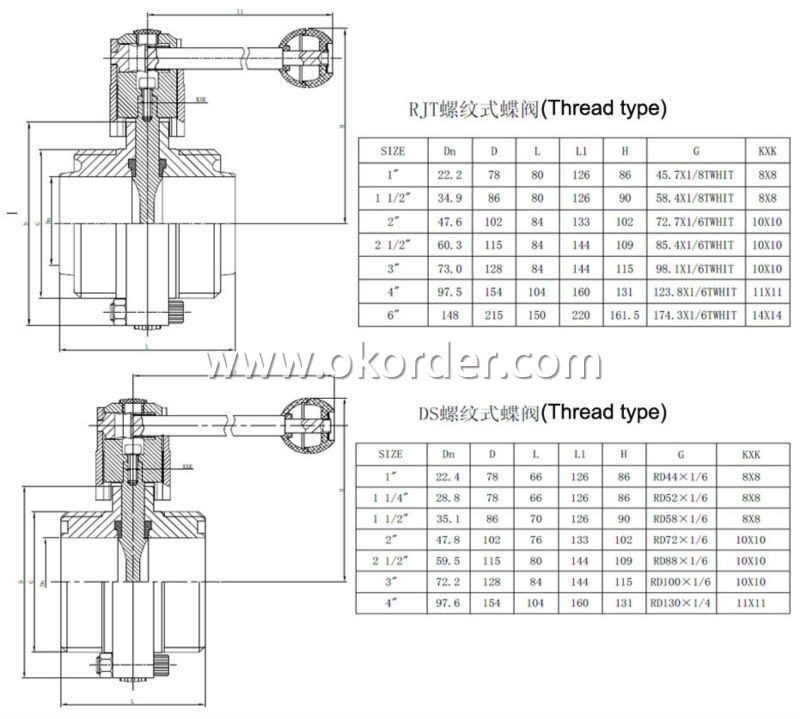

Drawing Example:

Specifications Of High Quality Flanged Wafer Type Butterfly Valve:

Nominal bore: 1-60"

Nominal pressure: ANSI150-300Lb

Connection type: flange type, clamp type

Temperature range: -20-600oC

Transmission type: worm, lever

Optional material: GGG500-7 , GG20 , WCB 304 316 316L

Packing: Wooden box

Features Of Double Flanged Butterfly Valve:

Body: cast iron, ductile iron

Metal seat and disc with EPDM O ring seal

Gear box operator

Features Of Wafer Butterfly Valve:

Size: 2" - 24"

Standard: ANSI, BS, DIN, JIS

Working pressure: PN16

Suitable media: water, oil and gas

This product adopts three-eccentric structure, has no friction between valve plate and valve seat, high flowrate and long service life and is able to increasingly tighten.

Product Advantages Of High Quality Flanged Wafer Type Butterfly Valve:

Small in size and light in weight and maintaince. It can be mounted wherever needed.

Simple, compact structure, quick 90 degree on-off operation.

Disc has two-way bearing, perfect seal, without leakage under the pressure test.

Flow curve tending to straight-line. Excellent regulation performance.

Various kinds of materials, applicable to different medium.

Strong wash and brush resistance and can fit to bad working condition.

Center plate structure, small torque of open and close.

Long service life. Standing the test of ten thousands opening and closing operation.

Can be used in cutting off and regulation medium

Production Flow Of High Quality Flanged Wafer Type Butterfly Valve:

Usage/Applications Of High Quality Flanged Wafer Type Butterfly Valve:

These products are widely used in water source projects, urban water supply and drainage, sewage treatment, electric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries.

Valves are used for regulating or cutting off liquids in pipelines. Liquids available include water, sewage, sea water, air, foodstuff and oil.

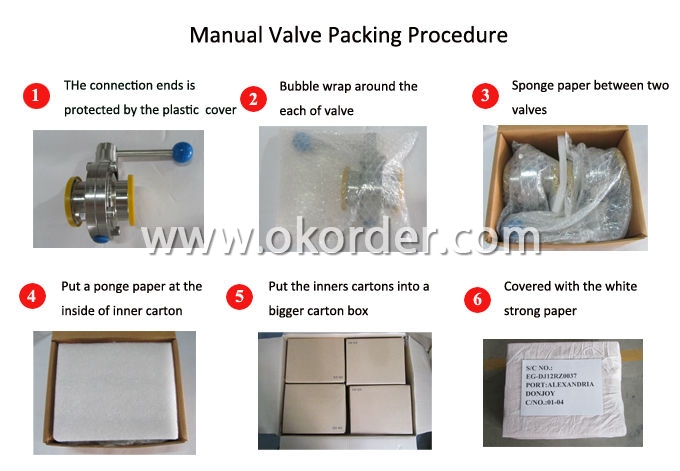

Packaging & Delivery Of High Quality Flanged Wafer Type Butterfly Valve:

- Q: In the pipeline attached building Atlas 05S502, in the middle of a water meter and check valve, the two sides are divided into two butterfly valve, want to ask why to arrange this way, what is the role of the two butterfly valve?

- Check the water gauge and check valve on both sides to facilitate the maintenance and replacement of water meter and check valve.

- Q: Butterfly valve is the control valve?

- The flow characteristics of butterfly valves can be approximately equal percentage characteristics, with the positioner can do adjust, is mainly used in large caliber, straight stroke control valve more than 200 volume weight will be great, it suggests using the butterfly valve.

- Q: What does the triplex of pneumatic butterfly valve mean?

- Upstairs is quite right, but now seems to use very little oil mist, and now generally referred to as "triple parts" as if: filter pressure reducing valve, solenoid valve, with the valve position feedback switch.

- Q: Where are the exhaust valves, mud valves and butterfly valves?

- The exhaust valve is suitable for the pipeline with working medium, so as to improve the efficiency of the water conveyance equipment and protect the pipe from deformation and rupture. Sludge discharge valves are suitable for use in floating waste water treatment plants, such as gypsum. Slag, scale power stations, smelters, sugar mills.

- Q: Butterfly valve model D373F-16C, ask God answers

- D butterfly valve, 3 turbo rotating, 7 pairs clip type, 3 eccentric F PTFE seal, 16 nominal pressure 1.6MPA, C valve body material, carbon steel

- Q: Gate valve, butterfly valve and so on can do the valve so that?

- Do a lot of use valve and butterfly valve, pneumatic / hydraulic, or electric device, automatic control valve, adjust its switch angle, so as to achieve the purpose of regulation. For example, in the factory, in order to ensure the top pressure, then the pressure regulating valve, the valve is automatically adjusted by a butterfly valve! And there is also pressure regulator, pressure regulator valve series is used independently. Of course the more, is mainly used to adjust the flow!

- Q: What is the meaning of American Standard butterfly valve B series

- American Standard flange connection is divided into A, B series. A series for normal flanges, B series for compact flanges. 24 "to no AB series, flange standards for B16.5, 24" above B16.47.

- Q: Butterfly valve sealing material has several?

- Nine: X1 (natural food gum), X2 (Heipalen), X3 (ethylene propylene rubber), X4 (neoprene), X5 (Ding Qing X6 (rubber), wear-resistant rubber (FPM), X7), X8 (silicon rubber), X9 (heat resistant ethylene propylene rubber)

- Q: Which is more expensive, gate valve or butterfly valve?

- Gate valve.Under normal circumstances, if you need to adjust the good point, to use the gate valve, and if better, you can choose the cut-off valve.But the price is also butterfly valve, gate valve, globe valve increasing.

- Q: Which is better, the round two lobe butterfly valve?

- Round type double butterfly butterfly valve is the first choice of Shanghai Machinery & Equipment Co., Ltd., the company is a professional design, manufacture and sale of central air-conditioning products at the end.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America;Asia;Africa |

| Company Certifications | ISO9001:2008 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 20-50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 8,350 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Flanged Wafer Type Butterfly Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords