Wafer Butterfly Valve For Water, Oil, Gas

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 Piece/year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Wafer Butterfly Valve

|

Standard or Nonstandard: |

Standard |

Structure: |

Wafer |

Pressure: |

Medium |

|

Power: |

Manual |

Material: |

Cast iron, Ductile iron, WCB, SS316,C954 |

Temperature of Media: |

Normal |

|

Media: |

Water, Oil, Gas |

Port Size: |

DN40-DN1200 |

Place of Origin: |

China |

|

Brand Name: |

Yue |

Certification: |

ISO9000, CE,CCS,DNV,ABS,TS | ||

Packaging & Delivery of Wafer Butterfly Valve

|

Packaging Detail: |

Each Piece into one bubble plastic bag, several pcs into one Wooden crate or according to customers requirements |

|

Delivery Detail: |

within 30 days |

Specifications of Wafer Butterfly Valve

1. MSS/API/BS design.

2. Size: DN40-1200.

3. Working pressure: PN10/16/25.

4. ISO9001/ABS/CCS/DNV/CE.

5. Flange: AWWA/BS/EN etc.

Usage/Applications of Wafer Butterfly Valve

1. Newly developed facilities ensure high and stable quality.

2. Enable to supply UL/FM valves.

3. Experienced technology

4. Excellent after-sale service to satisfy customers.

5. Sufficient capacity ensures prompt delivery.

6. Continuous quality improvement and new designs development.

7. Reasonable and stable price

8. Meets different countries standards, such as ANSI,DIN,BS etc.

Working pressure: 10Bar/16Bar/25Bar

Face-to-face:

API 609 Table 1

ISO 5752 Series 20

EN 558 Series 20 (DIN 3202 T3 K1)

BS 5155 Series 4

Flange accommodation:

ANSI B16.1 Class125/150

AWWA C207

MSS SP44 Class150

DIN 2501 PN6/10/16

EN1092-2 PN6/10/16 BS10 Table D/E

JIS B2220 5K/10K/16K AS4087 PN14/16

Top Flange: ISO5211

Tightness check:

API 598

ISO 5208,

EN12226-2

|

Pressure Temperature Ratings | |

|

working pressure |

16bar/25bar |

|

testing pressure |

shell:24bar/37.5bar |

|

seal:17.6bar/27.5bar | |

|

working temperature |

-20 degree to 110 degree EPDM seat |

|

-10 degree to 80degree NBR seat | |

|

suitable media |

Water, Oil& Gas |

|

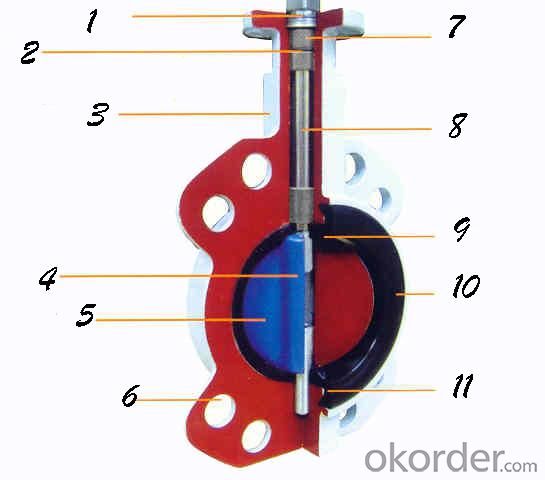

Material Specification | |||

|

Part |

Material |

ASTM | |

|

Valve Body |

Cast iron |

A126 Class B | |

|

Ductile iron |

A536 Gr.65-45-12 | ||

|

Valve Disc |

Ductile iron |

A536 Gr.65-45-12 | |

|

Bronze |

B148 C95400 | ||

|

Stainless steel 304 |

A351 CF-8 | ||

|

Stainless steel 316 |

A351 CF-8M | ||

|

Valve Shaft |

Stainless steel 410 |

A276 S 410 00 | |

|

stainless steel 431 |

A276 S 410 00 | ||

|

Valve Seat Ring |

EPDM/NBR | ||

|

O-Ring |

EPDM/NBR | ||

|

Bushing |

PTFE | ||

|

Bronze |

B62 C83600 | ||

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: What's the difference between a clip on handle butterfly valve and a turbo butterfly valve? Where are they used?

- 1, the drive mode is different (handle or turbine), mainly based on the size of the valve and the opening and closing torque to decide.2. The butterfly plate of the worm valve is installed in the direction of the diameter of the pipe. In the butterfly valve body cylindrical channel, the disc shaped butterfly plate revolves around the axis, the rotation angle is 0 degrees ~90 degrees between, when rotates to 90 degrees, the valve opens the card completely.3, clip type butterfly valve is to use double headed bolts to connect the valve between the two pipe flanges, flange butterfly valve is a valve with a flange, bolt with the valve flange at both ends connected to the pipe flange.

- Q: Import electric butterfly valve which brand is more reliable?

- Recommend Sichuan Ding Heng petroleum machinery company sales agent SPM butterfly valve and FMC butterfly valve, we are partners for many years, have been working together are very happy.

- Q: How can I get the fire signal butterfly valve?

- 1, the signal butterfly drive by the worm gear drive shaft and butterfly plate rotation, realize the opening and closing and control flow. 2, rotating the handwheel worm gear to the disc to open and close and adjust the flow to the handwheel clockwise rotation for the valve closed. 3, worm gear is arranged in the box body micro switch has two forms: A, in the gear box body is provided with open and close direction two microswitches, respectively, when the valve fully open and close action, connected to the control room "valve open" valve off "light source, the quasi it shows the state of the valve switch. B, in the driving device is arranged in the box body the microswitch (disc position close to 0 degrees), when the butterfly plate from 0 degrees to 40 degrees when the position of a micro switch, the output valve closed signal, 40 degrees to 90 degrees when the position of another pair of normally closed output valve opening signal. A cam that adjusts the touch microswitch and shows the different positions of the disc.

- Q: The flow ratio of area and maximum flow area of the valve is? If it refers to the opening of the valve rotation angle? Butterfly linear closure refers to the butterfly valve at constant angular velocity close? When the change trend of flow is what? These valves problem bothering me for a long time,

- Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis rotation, so as to achieve the opening or closing or adjustment; actuators have electric or pneumatic, and so on, through the transmission device to drive the stem, valve plate rotation;

- Q: Butterfly valve general use occasions

- Valve is especially suitable for low differential pressure, large diameter, large flow of gas and slurry liquid. For general control valve, DN300mm is big valve, only individual to DN450, and for the butterfly valve, DN500 below is a small valve, DN500 ~ 1000 is the standard valve, the largest butterfly caliber up to 9m. Visible, large diameter pipe with the main butterfly valve.

- Q: What are the classification criteria for pneumatic butterfly valves?

- The pneumatic clamp butterfly valve has a novel structure, and the structure of the valve body is short clamp structure for meeting the narrow space of the pipeline, and the outer zero leakage is in place, and the internal leakage conforms to the national standard.Pneumatic butterfly valve, connection flanges, the sealing clamp, lined with NBR, EPDM rubber, heat resistant ethylene propylene rubber, natural rubber, chloroprene rubber, fluorine rubber, PTFE, medium according to the chemical properties have a more rational choice.Pneumatic fluorine valve, corrosion fluorine valve using the bisection valve combination two, valve seat and valve liner valve work, integration, only full plastic seat and lining plastic disc contact with the media, the product can withstand any corrosion in molten alkali metal and fluorine elements ", which D71F46 stem and disc board (forging) as a whole, the surface is uniformly coated with a layer of FEP.

- Q: Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- One more 3 in D71X-10 stands for adding a worm gear to the valve. What are the same, the difference is driven by the handle into the drive, gear drive, worm gear drive for large caliber butterfly valve a little less, because the valve torque is big, big, hard to handle and can rotate, and if the worm, you can turn a few laps handwheel. If there are other questions, we can continue to ask questions, the city butterfly valve manufacturers

- Q: Butterfly valves are widely used in 2.0MPa below the pressure and temperature of not more than 200 degrees of various media, right?

- First of all, is not the butterfly valve butterfly valve.Butterfly valve in the valve around the fixed axis rotating valve, called butterfly valve.1., as a sealed butterfly valve, it has been developed rapidly since the appearance of synthetic rubber, so it is a new type of shut-off valve. In our country until 1980s, the main role of butterfly valves in low-pressure valves, valve seat using synthetic rubber, by 90s, hard seal "metal seal" butterfly valve to rapid development. There are a number of valve factory can produce steady pressure metal seal butterfly valve, butterfly valve shall be shipped to a broader area.2. butterfly valves can transport and control the medium with water, condensed water, recycled water, sewage, sea water, air, gas, liquid gas, dry powder, mud, fruit pulp and a mixture of suspended solids.The domestic butterfly valve parameters are as follows:Nominal pressure: PN0.25 - 4.0MPaNominal diameter: DN100 - 3000mmWorking temperature: less than or equal to 425 DEG C

- Q: Which is better, the round two lobe butterfly valve?

- Can be directly installed in the ventilation pipe, connected with the wind pipe, used to control the speed, adjust the indoor air, the double structure diagram can reduce the space length of the blade is unfolded, and also has the characteristics of small airflow resistance, convenient adjustment etc.

1. Manufacturer Overview

| Location | Suzhou, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | West Europe, South Africa, the Middle Eas |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 500 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 18,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Wafer Butterfly Valve For Water, Oil, Gas

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 Piece/year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches