Ductile Iron Butterfly Valve Of Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

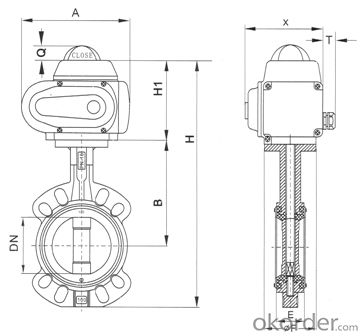

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What does the J41Y-100I valve type mean?

- J41Y-100I flange type chrome molybdenum steel valve forgingJ represents the cut-off valve, 4 (flange) on behalf of his connections, 1 (straight) on behalf of his structure, Y (seal) on behalf of his seat sealing surface or liner material code, 100 is the nominal pressure value, I (chrome molybdenum steel) is the code of the body material

- Q: the use of natural connections, is strictly prohibited counterparts. What do you mean by "strong opposition"?

- Pro, strong counterpart refers to the valve in the pipeline connection, generally refers to the thread connection or welding to connect the valve, the valve and pipeline connection imposed by the larger external force, it will cause great stress and plastic deformation, easy to cause the valve to open or close the lax.

- Q: What are the main equipments for valve production?

- I know these gate valves, globe valves, plug valves, ball valves, butterfly valves, needle valves, diaphragm valves, check valves, and throttle valves

- Q: and today the boss told me that I would like to do a valve of the commodity inspection information, and nothing else to me, which master taught meI am a professional intern, our company is doing the valve outlet, today my boss asked me to do a valve inspection data, what other data are not for me, which foreign trade master teach me ah, depressed ah ah ah???

- If the customs clearance order is required, the boxes, invoices, and contracts will not be needed. If the customs clearance is made, which port should be provided, the value of the goods, the weight, and the HS code for those

- Q: What kind of valve is it? How do you see the status of the switch?

- Globe valve, not ball valveClockwise (Bell) needle to reduce the flow to the end of the shutdown, the counter clockwise to open. You can turn the multi circle plate will also lift up and down. The spindle, to the top is open, down to the edge off.The ball valve has a strip handle, the line is connected, and the cross is turned off

- Q: What's the difference between valves and valves without valves?

- The difference between a valve with and without a valve is that it has the advantage of having the valve exhaust. The advantage of the valve is that it can control the amount of exhaust and prevent the discharge of other fluids.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: What are the specifications of the valves PN25, DN50?

- Upstairs professional level can be seen very solid.... Clap your hands... Popular speaking, that is, the valve bore is 50, resistance to pressure is below 25, is no problem.

- Q: someone else's home has valves, but also checked nothing, in addition to telephone repair, there are other ways? emergency

- That's a lie. Other people's homes do not necessarily have water.You need to keep on pressing the property.

- Q: How to better maintain the valve?

- Use and maintenanceThe maintenance of the aim is to extend valve life and ensure reliable opening and closingThe stem threads, often with the stem nut friction, to a little yellow dry coating oil, molybdenum disulfide or graphite, lubricationWe do not often open and close the valve, but also on a regular basis handwheel on the stem threads to add lubricant to prevent bitingThe outdoor valve, to increase the protection sleeve on the stem, to rain, snow, dust and rustIf the mechanical valve system to be fixed, to add time to the gearbox oil

- Q: The low pressure in our factory is below 1.6Mpa, medium pressure is 2.5-6.4MPa, high pressure is 10-80MPa.Where's qusetion:1.6-2.5Mpa??? Which section does it belong to?. I think many of them are defined on the Internet But I didn't say, where's 6.4-10Mpa?

- No 1.6-2.5Mpa levels are included in the range of the mid pressure valve.

Send your message to us

Ductile Iron Butterfly Valve Of Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords