Building Steel Rods SAE 1006 1008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Steel Rods

Description of Building Steel Rods

1, Diameter: 5.5mm-10mm Building Steel Rods

10m- 40mm Building Steel Rods

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Building Steel Rods

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

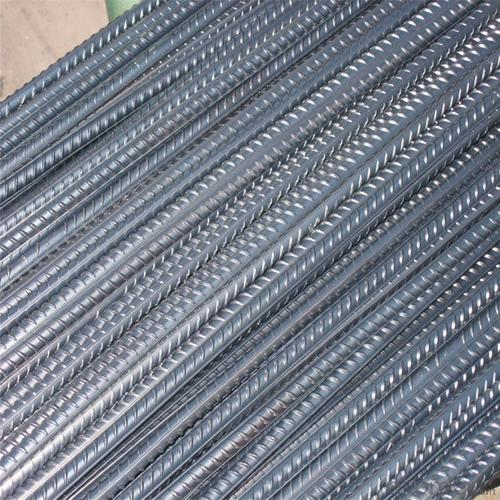

Products Show of Building Steel Rods

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to the impact resistance of products?

- Special steel, which is also referred to as high-strength or high-performance steel, plays a critical role in enhancing the impact resistance of various products. This particular type of steel is designed specifically to possess exceptional strength, toughness, and durability, making it highly resistant to deformation and fracture under conditions of high stress. One of the main contributing factors to the impact resistance of special steel is its composition. Special steel often contains alloying elements such as manganese, chromium, nickel, molybdenum, and vanadium, which are added to improve its mechanical properties. These alloying elements provide the steel with increased hardness, tensile strength, and resistance to wear, corrosion, and fatigue. Consequently, products made from special steel can withstand heavy impact loads without deforming or breaking. Furthermore, the microstructure of special steel plays a crucial role in its impact resistance. Advanced manufacturing techniques can be employed to finely adjust the steel's microstructure, achieving a desirable combination of strength and toughness. Special heat treatment processes, like quenching and tempering, can further refine the microstructure, resulting in a material that can effectively absorb and dissipate energy. This renders special steel highly resistant to cracks and fractures, even when subjected to sudden and severe impacts. In addition to its inherent properties, special steel is often utilized in the form of engineered components or structures that are specifically designed for impact resistance. For instance, in the automotive industry, special steel is employed in manufacturing components such as crash beams, bumpers, and roll cages. These components are designed to absorb and distribute impact energy, safeguarding the vehicle and its occupants during accidents. Overall, special steel significantly contributes to the impact resistance of products by providing superior strength, toughness, and durability. Its distinctive composition, microstructure, and design enable it to withstand high-stress conditions and effectively absorb impact energy. Consequently, products made from special steel offer enhanced safety and reliability, making them suitable for a wide range of applications in industries such as automotive, aerospace, construction, and defense.

- Q: What are the factors that determine the cost of special steel?

- The factors that determine the cost of special steel include the cost of raw materials, production and manufacturing processes, market demand and supply dynamics, the complexity and uniqueness of the steel alloy, any additional treatments or coatings applied, and overall market conditions such as inflation and currency fluctuations.

- Q: What are the main advantages of using special steel in the aerospace industry?

- The main advantages of using special steel in the aerospace industry are its high strength-to-weight ratio, excellent corrosion resistance, and superior heat resistance. Special steel allows aircraft to be lighter, yet still maintain the necessary structural integrity and safety standards. Its resistance to corrosion ensures the longevity of the aircraft, even in harsh environments. Additionally, special steel's ability to withstand high temperatures makes it suitable for use in jet engines and other crucial components, ensuring optimum performance and safety in aerospace applications.

- Q: How does special steel perform in abrasive wear applications?

- Special steel performs well in abrasive wear applications due to its high hardness, toughness, and resistance to deformation. It can withstand the constant friction and impact caused by abrasive particles, resulting in minimal wear and extended longevity of the material. Additionally, special steel often has excellent heat resistance, corrosion resistance, and good dimensional stability, making it a reliable choice for abrasive wear applications.

- Q: What are the different methods of preventing hydrogen-induced cracking in special steel?

- To prevent hydrogen-induced cracking in special steel, various methods can be utilized: 1. Preheating the steel prior to welding or any high-temperature process can lower the possibility of hydrogen-induced cracking. This technique slows down the cooling rate, allowing hydrogen to dissipate before causing any cracks. 2. Employing specific heat treatment processes like stress relieving or post-weld heat treatment helps alleviate hydrogen-induced cracking. These processes decrease residual stresses and facilitate hydrogen diffusion, minimizing the risk of cracking. 3. Opting for steel alloys with higher resistance to hydrogen-induced cracking is an effective preventive measure. Certain steel compositions, such as low carbon or low alloy steels, demonstrate reduced susceptibility to cracking in the presence of hydrogen. 4. Ensuring proper control of hydrogen during welding is crucial. This can be achieved by utilizing low-hydrogen welding consumables, such as electrodes, and guaranteeing adequate shielding gas coverage to prevent atmospheric moisture from contaminating the weld. 5. Managing stress on the steel during welding or operation is essential in preventing cracking. This can be accomplished by employing appropriate welding techniques, such as avoiding excessive heat input or rapid cooling rates, and minimizing the introduction of tensile stresses during welding. 6. Applying protective coatings or surface treatments acts as a barrier against hydrogen absorption, reducing the risk of hydrogen-induced cracking. 7. Optimizing the welding parameters, including current, voltage, and travel speed, can help reduce the chances of hydrogen-induced cracking. Adjusting these parameters allows control over heat input and cooling rate, thus minimizing hydrogen absorption and subsequent cracking. It is important to note that a combination of these preventive measures is often necessary to effectively mitigate the risk of hydrogen-induced cracking in special steel. Additionally, implementing proper inspection and quality control procedures is crucial to ensure the integrity of the steel and detect any cracks or defects.

- Q: What are the different methods for improving the corrosion resistance of stainless special steel?

- There are several methods for improving the corrosion resistance of stainless special steel. Some of the common methods include alloying the steel with elements such as chromium, nickel, and molybdenum, which enhance its resistance to corrosion. Another method is passivation, which involves treating the steel with an acid solution to remove any surface contaminants and create a protective oxide layer. Coating the steel with materials like paint, powder coating, or electroplating can also improve its corrosion resistance. Additionally, proper cleaning and maintenance practices, such as regular removal of dirt and debris, can help prevent corrosion and maintain the steel's resistance over time.

- Q: How does molybdenum improve the performance of special steel?

- Due to its unique properties and characteristics, molybdenum is crucial in enhancing the performance of special steel. Its role is multi-faceted and includes improving strength and toughness, increasing hardenability, enhancing corrosion resistance, and improving high-temperature strength and creep resistance. One of the primary benefits of molybdenum is its ability to significantly improve the strength and toughness of steel, making it more durable and resistant to deformation. This is achieved by forming a solid solution with iron, resulting in a fine-grained microstructure and reducing the formation of brittle phases in the steel. Another advantage of molybdenum is its impact on the hardenability of steel. It allows the steel to be heat-treated to achieve the desired mechanical properties. This is particularly important in the production of special steel, where high strength, wear resistance, and thermal stability are often required. By enabling effective heat treatment, molybdenum ensures that the steel can be processed to meet specific performance requirements, such as hardness, toughness, and dimensional stability. Moreover, molybdenum enhances the corrosion resistance of special steel, making it suitable for challenging environments. It forms a protective oxide layer on the steel's surface, acting as a barrier against corrosive substances like acids, alkalis, and salts. This corrosion resistance is crucial in applications where the steel is exposed to harsh conditions, such as marine environments, chemical processing plants, and oil and gas industries. Furthermore, molybdenum improves the high-temperature strength and creep resistance of special steel. It enables the steel to maintain its mechanical properties even at elevated temperatures, making it suitable for applications where the steel is subject to prolonged exposure to heat or mechanical stress. In conclusion, molybdenum plays a vital role in enhancing the performance of special steel by improving its strength, toughness, hardenability, corrosion resistance, and high-temperature properties. These attributes make molybdenum an essential alloying element in the production of special steel for various industries, including automotive, aerospace, energy, and tool manufacturing.

- Q: How does special steel contribute to the circular economy?

- Special steel contributes to the circular economy by offering durability, recyclability, and extended product lifecycles. Its high strength and corrosion resistance properties make it ideal for long-lasting applications, reducing the need for frequent replacements. Additionally, special steel can be easily recycled and repurposed, minimizing waste and conserving resources. This promotes a more sustainable and environmentally friendly approach to manufacturing and consumption, aligning with the principles of the circular economy.

- Q: Can special steel be used in the printing industry?

- Yes, special steel can be used in the printing industry. It is commonly used in the manufacturing of printing machinery, such as printing presses, due to its high strength, durability, and resistance to wear and tear. Special steel components can help enhance the precision, reliability, and efficiency of printing processes, resulting in improved print quality and productivity.

- Q: What are the different aerospace grades of special steel?

- There are several aerospace grades of special steel that are commonly used in the aerospace industry. These grades are specifically designed to meet the high-performance requirements and stringent safety standards of aerospace applications. Some of the different aerospace grades of special steel are: 1. 300M: This grade of steel is known for its exceptional strength and toughness. It is commonly used in aircraft landing gears, structural components, and other high-stress applications. 2. 4340: 4340 steel is a widely used alloy steel in aerospace applications. It has high strength and good hardenability, making it suitable for gears, shafts, and other critical components. 3. 17-4 PH: This stainless steel grade offers a combination of high strength, corrosion resistance, and good toughness. It is commonly used in aerospace applications such as aircraft engine components, landing gears, and structural parts. 4. 15-5 PH: Similar to 17-4 PH, 15-5 PH stainless steel also offers high strength and corrosion resistance. It is often used in aerospace applications where weight reduction is crucial, such as aircraft structural components. 5. 300 series stainless steels: Grades like 301, 302, and 304 are commonly used in aerospace applications due to their excellent corrosion resistance, low magnetic permeability, and good strength-to-weight ratio. These steels are used in aircraft structures, fuel tanks, and other components exposed to harsh environments. 6. Titanium alloys: While not technically steel, titanium alloys are widely used in aerospace applications due to their exceptional strength, low density, and high corrosion resistance. Grades like Ti-6Al-4V are commonly used in aircraft structures, engine components, and landing gears. These are just a few examples of the different aerospace grades of special steel used in the industry. Each grade offers specific properties and characteristics that make them suitable for various applications in the aerospace field.

Send your message to us

Building Steel Rods SAE 1006 1008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords