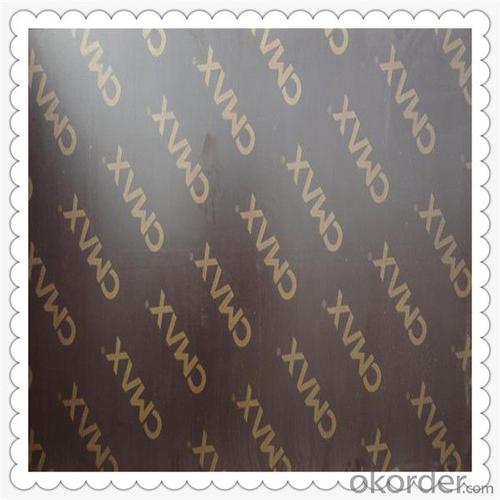

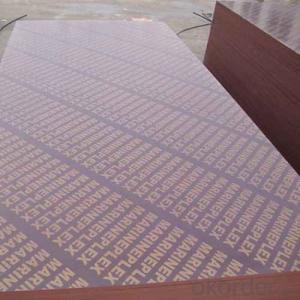

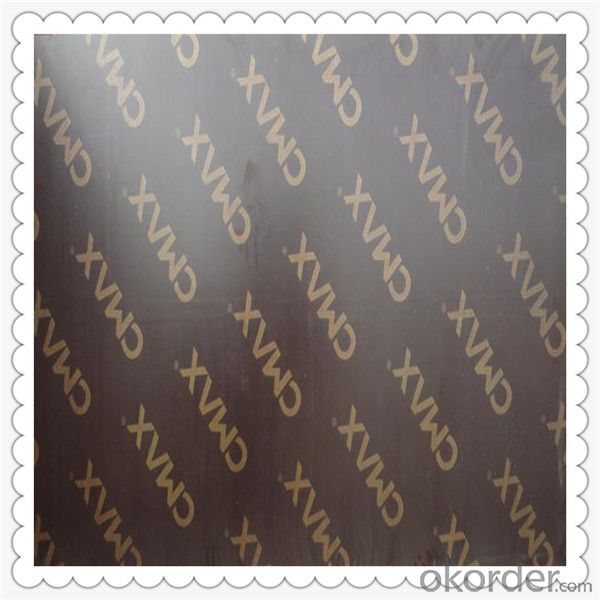

Brown Color Film Faced Plywood with CMAX Logo for Construction Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brown Color Film Faced Plywood with CMAX Logo for Construction Usage

Product Description:

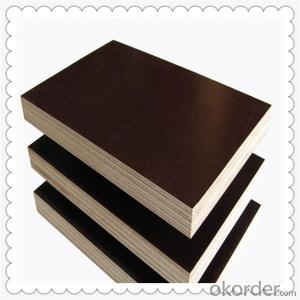

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Usage: Indoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Teak

· Face/back: teak, oak, beech, ash walnut, sapele etc

· Thickness: 2.6mm,3.0mm,3.6mm,4.0mm,4.6mm,5.2mm 12mm,9mm,as your request

· Core: poplar, combi, hardwood, MDF

· Glue: melamine: MR, E2,E1

Film faced plywood is lightweight, resistant to corrosion attack and water, easily combined with other materials and easy to clean and cut. Treating the film faced plywood’s edges with waterproof paint makes it highly water-and wear-resistant.

Product Specification:

Name | Fancy Plywood |

Size | 1220mmx2440mm or 915x2135mm |

Thickness | 2.0mm---18mm |

Thickness Tolerance | ±0.2mm to ±0.3mm |

Core | poplar core & harewood core, combi or as agreed. |

Face/Back | Nature ash, Sapeli, Red Oak, White Oak, Teak, steam Beech, Okoume, Cherry, Walnut, |

Glue | WBP, Melamine, E0, E1, E2, MR |

Grade | AAA, AA, A or as agreed. |

Moisture | Below 12% at time of shipment. |

Usage | Decoration, furniture, construction. |

Package | Inter packing: 0.20mm plastic bag. Outer packing: pallets are covered with plywood or carton and then steel for strength. |

Delivery time | 20 days on receipt of deposit or original L/C. |

Min Order | 50 cubic meter |

Payment terms | L/C at sight, T/T30% as deposit, |

Supply ability | 4000 cubic meter/month |

Main market | Middle East, Southeast Asia, East Asia, South Asia Africa etc. |

Packaging & Delivery:

· Inter packing: 0.20mm plastic bag.

· Outer packing: pallets are covered with plywood or carton and then steel for strength

· Delivery Detail: 30 days after receiving LC or deposit

Company Info:

China National Building Material Group Corporation (CNBM for short) was establish in 1984, a Central Enterprise under direct supervision of State- owned Assets Supervision and Administration Commission of the State Council of China.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Paper honeycomb sandwich panels about how much the price

- Do not know what you do with, I see you most recently has been consulting honeycomb board problems, I do pp honeycomb board

- Q: How to install the wall rock wool sandwich panels

- 1, handling the plate should also be lifted at both ends, so as not to damage the appearance of oxide film or coating. When installing the wall panel, only one board can be lifted at one time. It should be used for the special fixture supplied by the manufacturer of the rock wool sandwich panel. Lifting process to slow down, to use the wind rope to be controlled to prevent the wall with the device has been bump, scaffolding raised parts with soft data package. 2, sandwich plate fixation method: one is the self-tapping screw through the wall directly to the wall in the secondary structure. Another method is the self-tapping screw connected directly to the wall sub-structure via the coupling.

- Q: Sandwich panel sandwich panel characteristics

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandboard is a common product in the current building materials, not only can a very good flame retardant and environmentally friendly sandwich board English name: laminboard sandwich panel products are made of two layers of metal panels (or other material panels) and Directly in the middle of the panel foam, mature molding of the polymer core insulation composition. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q: I've been on a diet for a week now and because of my new low calorie food i eat it's a struggle to even get to 1200 calories by the end of the day! I've been eating 3 sandwiches a day. They consist of whole wheat bread, one slice of ham, and one slice of cheese each. But i'm afraid eating six slices of whole wheat bread will make me gain weight even if I am eating them for the calories to get to at least 1200. Should I stop or is this alright?

- That all depends! It can be bad in the long run if you aren't getting balanced nutrients from the sandwiches. With just ham and cheese, there's no way you could be getting everything your body needs nutritionally! Try adding variety into your sandwiches using lettuce, tomatoes, different meats, different dressings, new veggies, etc. Of course, this doesn't mean to go overboard with any one ingredient - keep it healthy. And remember, don't always use fat free dressings; a lot of the time, when there are other veggies involved, they are best consumed with a healthy fat source for best absorption. Regarding the bread... whole wheat bread isn't always what it seems. Real whole wheat bread is made from real whole grains, and you must check the ingredient panel to ensure this is what you are eating; there has been a bit of trickery in the bread industry. The first ingredients should contain items such as whole wheat flour, 100% rolled oats, whole grain corn, etc. Any enriched flour, even if whole wheat, is not what you're after. Sandwiches can be great as long as they are balanced nutrition-wise, so if you really like 'em, I wouldn't say they are a problem. Just make sure your caloric intake is correct for your daily needs, and that you're getting some variety.

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Magnesium cement curing to release a high heat, generally in the 1000 ~ 1350J / gMgO, and the heat release rate is very fast, the highest reaction system center temperature up to 150 degrees Celsius. Ordinary Portland cement hydration heat is only 300 ~ 400J / g, can be seen magnesite cement is the ordinary cement hydration heat 3 to 4 times. As can be seen from the above data, especially in the summer high temperature production, must strictly control the magnesite cement curing process. At present in Hebei Wen'an, Cangzhou area, in order to save production space, usually finished a board, and then according to this board for the operating platform in the above do 3 to 5, we all know, thermal conductivity of foam material is poor, and Ling Magnesium cement curing is a fast high heat process, so the production often encountered due to exotherm is too high and burned foam board situation, that is, "burn board" "hollowing" phenomenon.

- Q: Rock wool sandwich panel price rock wool sandwich board how much money a square meter

- This depends on the weight of rock wool, as well as color steel kind. If you need, we plant production. This answer is provided by Hebei Chengxin chemical building materials, if satisfied please adopt.

- Q: Magnesium Sulfide sandwich color steel plate

- Henan Ming-chen purification Technology Co., Ltd. mainly produces and sells magnesium sulfate fire board, magnesium sulfide mechanism board, magnesium sulfide manual board, purification equipment (return window, diffuse board, medicine cabinet, purification lamp, color steel plate series, Purification of special aluminum, plate exhaust, residual pressure, air conditioning units, ozone generator, efficient air supply, air filter, laminar flow hood, clean sampling vehicles, transfer window, air self-purification, air shower), to undertake purification engineering. I uphold the company in good faith-based, quality-oriented, service-oriented concept for the majority of customers to provide quality services.

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: Is the sandwich panel a mezzanine? What is the effect of painting? How long can I use life on the cabinet? Best example! My house in the decoration What is the cost of a sheet plus paint? Will the board be put on the floor after painting and painting?

- Yes, but there is a base of ash and primer

Send your message to us

Brown Color Film Faced Plywood with CMAX Logo for Construction Usage

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords