British Pressed Grider Coupler for Scaffolding Q235 Q345 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

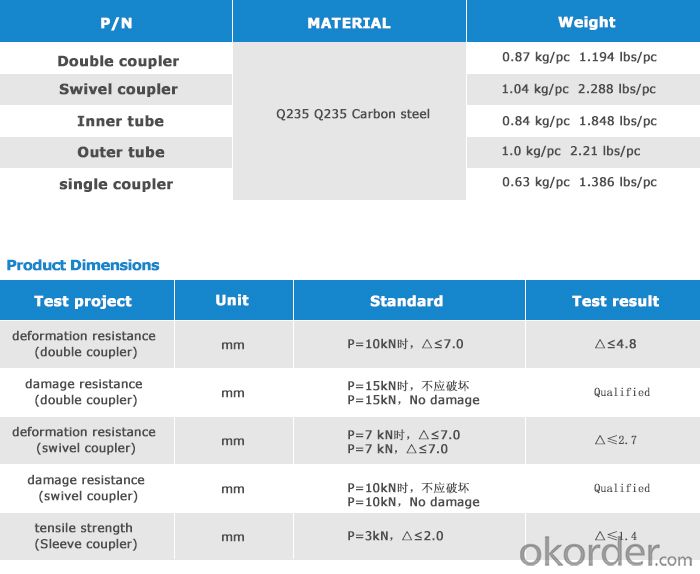

Quick Details of British Pressed Girder Coupler for Scaffolding

Material :SPHC

Production Standard :JIS

Applications :Construction

Package :In bag and pallet

Futures of British Pressed Girder Coupler for Scaffolding

Scaffolding coupler is the connecting hardware between the steel rail and rail bearing.

The Couplers are used to fix the steel rail on rail bearing to keep the rail gauge and prevent their opposite vertical and horizontal movements.

The good scaffolding couplers always consider design with less coupler system accessories for easy installation & disassembly.

Choose the durable & flexible & high strength couplers can firmly connect the steel rail and rail bearing.

Especially recommend the flexible couplers for concrete sleeper moulds application due to enough flexibility requirement from concrete sleeper

Our scaffolding couplers are with dual anti-rust processing (deactivation & galvanizing) for a longer lifespan compared to the common couplers.

Adapting full steel plate with cold press molding, our scaffolding couplers are with advanced structure design.All scaffolding couplers are with very high strength & toughness much higher than international general coupler standards. They totally eliminated the safe hazard compared to common iron casted couplers which easily cause the safe hazard due to scaffolding system collapsing accidents resulted by coupler fracture.

Our scaffolding couplers with superior stability & high load bearing capacity are popularly used in various construction/engineering applications.

The low-cost scaffolding couplers overcome the point & line fitting problems between couplers and tubes due to the Max Joint Area and cause no safe hazard resulted by steel tube slip. Greatly reinforced the mechanical properties & safety to the scaffolding and prolong the couplers lifespan.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Erection of scaffolding accessories

- Erection of scaffolding accessories:Door frame should be installed from one end to the other end of the extension, and layer by layer to change the direction of the set, not the opposite. After the completion of one step, should check and adjust its level and verticality. Scaffolding should be built around the building, continuous, synchronous erection elevation, in the form of a closed structure around the building; if not closed, the scaffold should be added at both ends of the wall.

- Q: What are the advantages and disadvantages of the fastener type steel pipe scaffold and bowl buckle steel tube scaffold

- (4) the bearing capacity is large: the vertical rod connection is a coaxial core socket, and the cross bar is connected with the vertical rod by a bowl buckle joint. And the axial line of each member is placed at one point, and the node is in the plane of the frame. (the entire frame bearing capacity, about the same clear fastener type steel tube scaffold condition is improved by more than 15%,)

- Q: I would like to ask how much scaffolding steel prices, scaffolding steel pipe use what are the requirements?

- The general price of 3800-4200 yuan per ton, you need to see the material and specifications.1 scaffolding steel pipe material Q195, Q215 or Q235, 2 scaffolding steel pipe specifications of phi, phi, phi, phi, phi, phi, 3.25, phi, phi, phi, 2.752, 5, 3 scaffolding steel pipe length of 1-6 meters, half a meter specifications; according to customer requirements specifications4 scaffolding steel pipe standard SY/T5768-

- Q: The role of the external scaffolding and the relevant provisions?

- These two functions are often concurrent. With the protection of the role of security, in order to play the role of height operation; can not guarantee the safety of the role, the construction personnel can not operate on the above. These two functions, the protection of human safety is the first. Construction workers in the scaffolding on the construction work, there is a sense of security, construction progress, the quality of the project is sufficient protection, in order to create good economic benefits. Otherwise, once the danger of scaffolding, will cause many casualties, causing significant losses. Therefore, in the development of scaffolding support programs and scaffolding erection, we must firmly grasp the quality.

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- nope! Cartilage piercings take about a year to fully heal up. Yes, you can get 2 separate bars, but let the piercer know thats what you want. Industrials are VERY hard to take care of. Make sure to listen to EVERYTHING the piercer says!

- Q: How long is the service life of disc scaffolding?

- Currently on the market there are many scaffolding accessories have been extended service

- Q: Fastener type steel pipe scaffold composed of components

- Fastener type steel pipe scaffold, mainly by the cross bar, vertical pole, fasteners (commonly used is the rotation button, right angle button, connecting rod), foot board, etc.

- Q: there is also shrubs and trees planted on the base of the wall and 14 feet from it

- Scaffolding and Cherry picker is your best option.

- Q: What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q: Who has external scaffolding construction program

- See the following table for permissible deviation of steel pipe:Item deviation check tool1 welded steel pipe size (mm) outer diameter 48Wall thickness 3.5-0.5 vernier caliperThe 2 ends of steel tube shear oblique deviation 1.7 feeler, corner rulerThe corrosion of 3 steel tube outer surface depth of less than 0.50 vernier caliper4 kinds of rod end bending L = 1.5m = 5, steel ruler5 pole bending 3m<l = 4m4m<l = 6.5m = 12Less than or equal to 20

Send your message to us

British Pressed Grider Coupler for Scaffolding Q235 Q345 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords