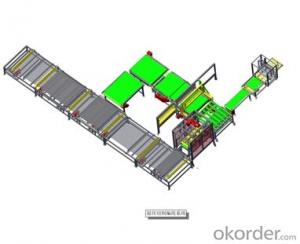

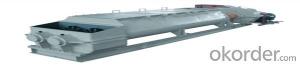

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: It is an extruding & molding equipment with strong points of reasonable distribution of grains, homogeneity of moisture content, fit for raw material with low plastic nature. It is suitable for material such as coal gangue, fly ash mixture, shale, clay, etc. It adopts hard gear reducer. Use powerful or oil lubricant, with long life span, and it can guarantee the extruding pressure. Clutch is operated by electro or pneumatic, easy to realize automatic control.

Technical Parameter:

Type | Diameter of reamer of extruding end (mm) | Capacity (pieces(standard brick size)/h) | Authorized pressure(Mpa) | Vacuum Degree(Mpa) | Installed capacity(kw) | Dimension(mm) |

JKY70/70-2.5 | 700 | 19000~24500 | 2.5 | -0.092 | 250+90+1.5 | 6687×6765×2846 |

JKY70/60-3.8 | 600 | 14000~15000 | 3.8 | -0.092 | 250+90+2.2 | 6632×6855×2866 |

JKY60/60-4.0 | 600 | 21000~24480 | 4.0 | -0.092 | 250+90+7.5+1.5 | 4819×6416×3065 |

JKY60/50-4.0 | 500 | 12000~18000 | 4.0 | -0.092 | 200+75+1.5 | 5844×6102×2796 |

JKY50/50-4.0 | 500 | 12200~13420 | 4.0 | -0.092 | 200+90+7.5+1.5 | 6904×5352×2820 |

JKB50/45-3.0 | 450 | 9800~15100 | 3.0 | -0.092 | 132+55 | 5375×4521×2723 |

JKR50/45-2.0 | 450 | 12000~16000 | 2.0 | -0.092 | 110+55 | 4900×4204×2723 |

- Q: What kind of configuration does the small semi-automatic cement brick machine include?

- Dosing Machine 2, Cement Warehouse 3, Cement Metering 4, Screw Conveyor 5, Base Material Mixer 6, Pigment Mixer 7, Bottom Belt Conveyor 8, Pigment Belt Conveyor 9, Elevated Horizontal Belt Conveyor 10

- Q: Brief introduction of cement brick machine

- This equipment is known as Mianshaozhuanji, that is to say the production of cement brick or hollow block, do not need sintering, through a short period of time can be shipped to the factory.

- Q: What are the brick-making materials?

- The brick machine is made of stone powder, sand, industrial waste, slag, slag and other raw materials for the brick, adding cement to produce brick machinery and equipment, through the replacement of mold, the production of different types of bricks such as tiles, blocks, bread bricks, , Slope protection brick.

- Q: Maintenance method of fly ash brick machine

- In order to make the machinery is often in a good state of technology, to ensure its reliability, improve work efficiency, extend the service life of the machinery to take a series of technical measures. Its main content is to clean, fastening, lubrication and adjustment-based, combined with the relevant inspection and testing work. Various types of machinery and equipment in the "use and maintenance manual" have a clear maintenance requirements, but in actual work this often does not cause enough attention, mainly as follows:

- Q: Automatic concrete brick machine bearing how to choose?

- After repair or adjustment of the discharge port, you should first use manpower to change the rotor, recognize the rotor and other parts do not conflict and stuck appearance and can be sensitive to change

- Q: The scope of application of building waste brick machine

- Concrete tiles made of construction waste, the strength is higher than the national standard of 20%. With the construction waste by the brick machine can be made sidewalk brick, brick walls, construction waste made of brick prices significantly lower than the clay brick, effectively saving land resources. To build waste brick as the starting point, you can vigorously develop new wall materials, and actively promote the industrial structure of building materials adjustment.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- In the water, because the vacuum brick machine is the first vacuum and water re-sintering, natural than ordinary brick coal time is short, forming fast.

- Q: How does the economical brick machine use the building waste brick?

- and then through the construction waste brick machine further processing into a building products. Therefore, the reuse of construction waste needs to be divided into two parts,

- Q: Brick machine operating procedures

- When the material in the rotary disk die hole is completely pressed, the main motor is turned off and the brick waste in the mold hole is cleaned. If you stop for a long time, you should disconnect the current. After stopping, should be the machine moving components of the connection bolts, oil cups, bearings and other preventive checks.

- Q: Cement brick machine related issues

- Main features: the rotation part of all sealed, the pressure of oil, circulation lubrication, without artificial oiling, so that part of the full lubrication of the rotation to reduce wear and tear, the main part of the selection of high-quality steel, fine processing, to meet the maximum working pressure of more than two times Strength, increase the quality of the triangular pulley, increase the rotational inertia, increase the crankshaft gear diameter, so that the rotation force greatly increased, so the use of the machine pressure, fuel consumption, high yield.

Send your message to us

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords