Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of A380 Aluminum Die Cast Description:

These are used when the casting alloy cannot be used in hot-chamber machines; these include aluminium, zinc alloys with a large composition of aluminium, magnesium and copper. The process for these machines start with melting the metal in a separate furnace. Then a precise amount of molten metal is transported to the cold-chamber machine where it is fed into an unheated shot chamber (or injection cylinder). This shot is then driven into the die by a hydraulic or mechanical piston. The biggest disadvantage of this system is the slower cycle time due to the need to transfer the molten metal from the furnace to the cold-chamber machine.

2.Main Features of the A380 Aluminum Die Cast:

Drawing: provide by customer, or we design as the sample.

Mold: Design and produce by ourself.

Product Material Option: A360, A380, ADC12, ADC3, AlsSi7Mg, AlSi12, AlSi9Cu3, etc.

SURFACE TREATMENT

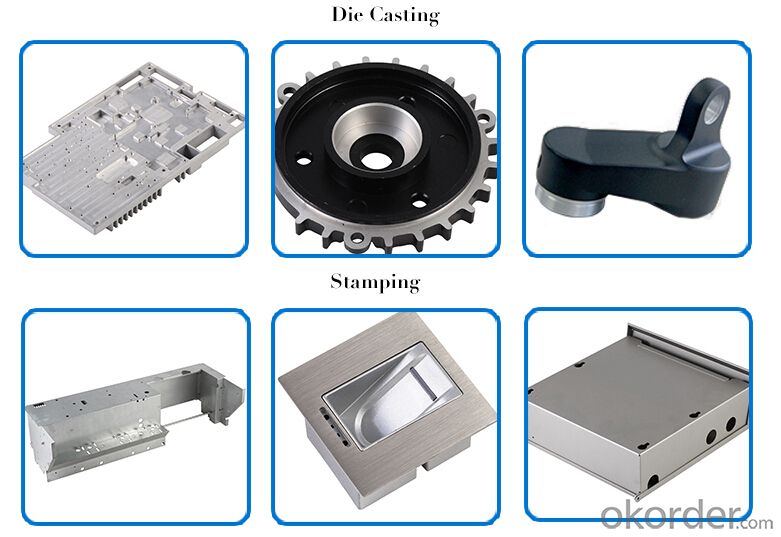

3. A380 Aluminum Die Cast Images

4. A380 Aluminum Die Cast Specification

Process | Material Grade | Weight range | Application |

Investment casting, sand casting, ESR casting Die casting Metal casting

| Iron: Grey iron, Ductile iron Steel: Carbon steel, Alloy steel, Stainless steel Nonferrous metal: Bronze, Brass, Al, Zinc, Ti, etc. | From 0.01Kg to 100 ton | Auto motive, agricultural machines, vessels, toolings, mining , oi l& gas machinery, locomotive industry, aerospace, hardware, contruction, engineering machinery, electrical equipment etc. |

5. RFQ

1).What kind of the materials can be provided?

Product Materials: mainly is Aluminum alloy. But we also can provide other material products for you: like zinc alloy, iron, stainless steel, plastic. Because we are very familiar with them, and better service for you

Mould Materials: H13,3Cr2W8V,4Cr5MoVlsi,SKD61,8407#

According to customers’ requirement

2).What your payment terms?

TT or LC

3).What is the privacy policy of your company?

We respect for all the customers, and make all the customers information confidential. We limit the scope of the information provided to third parties, and we allow its use only the customer permits.

- Q: Can aluminum profiles be used for lighting fixtures or systems?

- Yes, aluminum profiles can be used for lighting fixtures or systems. Aluminum is a lightweight and versatile material that is commonly used in the construction of lighting fixtures due to its durability, corrosion resistance, and heat dissipation properties. Aluminum profiles can be easily fabricated into various shapes and sizes, making them suitable for different lighting applications such as recessed lighting, track lighting, pendant lighting, and more. Additionally, aluminum profiles can be anodized or coated with different finishes to enhance their aesthetic appeal and protect them from environmental elements. Overall, the use of aluminum profiles in lighting fixtures or systems allows for efficient and effective lighting solutions while maintaining a sleek and modern design.

- Q: Are aluminum profiles suitable for electrical applications?

- Yes, aluminum profiles are suitable for electrical applications. Aluminum is a lightweight, durable, and corrosion-resistant material that can effectively dissipate heat, making it ideal for electrical components such as heat sinks, enclosures, and bus bars. Additionally, aluminum profiles can be easily customized and fabricated to meet specific electrical requirements.

- Q: What are the standard dimensions and sizes of aluminum profiles?

- The dimensions and sizes of aluminum profiles can vary depending on the specific application and industry. However, there are commonly used dimensions and sizes that are widely adopted across industries. Aluminum profiles are available in various shapes, including angles, channels, tubes, and bars. These profiles have dimensions that range from small to large, with measurements based on width, height, and thickness. For instance, aluminum angle profiles typically have widths and heights ranging from 1/2 inch to 8 inches, with thicknesses ranging from 1/16 inch to 1/2 inch. Aluminum channel profiles have widths from 1/2 inch to 12 inches, heights from 1/2 inch to 3 inches, and thicknesses from 1/16 inch to 1/4 inch. Aluminum tube profiles come in different outer diameters, ranging from 1/8 inch to 6 inches, with wall thicknesses from 1/32 inch to 1/4 inch. Aluminum bar profiles usually have widths from 1/8 inch to 12 inches, heights from 1/8 inch to 4 inches, and thicknesses from 1/16 inch to 1/2 inch. It's important to note that these dimensions and sizes serve as a general guideline, and custom dimensions or sizes may be required for specific applications. Furthermore, different countries or regions may have their own standards and variations in aluminum profile dimensions and sizes. Therefore, it's advisable to consult with manufacturers or suppliers to determine the specific dimensions and sizes that meet your requirements.

- Q: Can aluminum profiles be used in the production of audiovisual equipment?

- Yes, aluminum profiles can be used in the production of audiovisual equipment. Aluminum is a versatile and widely used material in various industries, including the audiovisual sector. Aluminum profiles can be used to construct frameworks, enclosures, and mounting systems for audiovisual equipment such as speakers, projectors, and television screens. The lightweight nature of aluminum makes it easy to handle and transport, while its high strength-to-weight ratio ensures durability and stability. Additionally, aluminum is corrosion-resistant, which is crucial for equipment that may be exposed to moisture or humidity. Aluminum profiles can also be easily customized and fabricated to meet specific design requirements, allowing for flexibility in the production of audiovisual equipment. Overall, the use of aluminum profiles in the production of audiovisual equipment offers numerous advantages in terms of strength, weight, corrosion resistance, and design possibilities.

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Here are a few guidelines to follow: 1. Regular cleaning: Aluminum profiles should be regularly cleaned to maintain their appearance and prevent corrosion. Use a mild soap or detergent mixed with water to clean the surface. Avoid using abrasive cleaners or steel wool as they can scratch the aluminum. 2. Avoid harsh chemicals: Harsh chemicals can damage the protective coating on the aluminum profiles. Avoid using strong acids, alkaline cleaners, or solvents for cleaning purposes. 3. Rinse thoroughly: After cleaning, make sure to rinse the aluminum profiles thoroughly with clean water. This will remove any residue from the cleaning solution and prevent streaking. 4. Dry thoroughly: After rinsing, dry the aluminum profiles completely using a soft cloth or towel. Moisture left on the surface can lead to corrosion, so it's important to ensure the profiles are completely dry. 5. Lubrication: If the aluminum profiles have moving parts or hinges, it's recommended to lubricate them regularly to ensure smooth operation. Use a lubricant specifically designed for aluminum to avoid any adverse effects. 6. Protective coatings: Some aluminum profiles come with protective coatings, such as anodized or powder-coated finishes. These coatings provide an extra layer of protection against corrosion and should be maintained as per the manufacturer's instructions. 7. Avoid abrasive cleaning tools: When cleaning aluminum profiles, avoid using abrasive cleaning tools such as brushes or scouring pads. These can scratch the surface and damage the protective coating. It's important to note that specific cleaning and maintenance instructions may vary depending on the type and finish of the aluminum profiles. Therefore, it's always advisable to refer to the manufacturer's guidelines for the best cleaning and maintenance practices for your specific aluminum profiles.

- Q: Are aluminum profiles suitable for gym equipment?

- Indeed, gym equipment can be made using aluminum profiles. Aluminum, being both lightweight and durable, can endure rigorous use and offer exceptional structural support. Its remarkable strength-to-weight ratio renders it perfect for gym equipment, granting effortless maneuverability while retaining stability and durability. Moreover, aluminum is resistant to corrosion, making it apt for environments abundant in moisture or humidity, like gyms or fitness centers. The versatility of aluminum profiles further allows for the customization of gym equipment to suit precise needs and requirements. Overall, aluminum profiles present a plethora of advantages for gym equipment, establishing them as an appropriate selection for fitness facilities.

- Q: What are the different color options for aluminum profiles?

- There are various color options available for aluminum profiles, depending on the desired aesthetic and functionality. Some common color options include: 1. Natural aluminum: This is the most basic color option, which showcases the raw and metallic appearance of aluminum. It is often chosen for its sleek, modern, and minimalist look. 2. Anodized finishes: Anodizing is an electrochemical process that creates a protective layer on the surface of aluminum, making it more durable and resistant to corrosion. This process also allows for a wide range of color options, such as black, bronze, gold, silver, and various shades of blue, red, green, and other vibrant colors. 3. Powder coating: Powder coating is another popular method to apply color to aluminum profiles. It involves applying a dry powder to the surface, which is then cured under heat to form a durable and attractive finish. Powder coating offers a vast array of color choices, including standard colors, metallic finishes, and special effects like textures and patterns. 4. Painted finishes: Aluminum profiles can also be painted using liquid coatings. This method allows for a broader spectrum of color choices, including custom colors to match specific design requirements. Painted finishes offer versatility and can be applied with different gloss levels, such as matte, satin, or high gloss. 5. Wood grain finishes: For those who want the appearance of wood without the maintenance, aluminum profiles can be finished with a wood grain pattern. This option combines the durability of aluminum with the warm and natural look of wood, offering a wide range of wood species and finishes. Ultimately, the choice of color for aluminum profiles depends on personal preference, architectural style, desired durability, and the overall design concept.

- Q: Is it possible to utilize aluminum profiles as a component in systems designed for covering interior walls?

- <p>Yes, aluminum profiles can be used for interior wall cladding systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. Aluminum profiles are easy to install and can be used in conjunction with various materials such as glass, stone, or wood to create a sleek and modern look. They are also customizable, allowing for a wide range of design options and can be powder-coated or anodized for different finishes and colors to match any interior design scheme.</p>

- Q: Can aluminum profiles be used for electrical applications?

- Aluminum profiles possess the capability to be utilized in electrical applications. Given its high conductivity, aluminum emerges as an ideal choice for facilitating electrical conduction. In the realm of electrical applications, aluminum profiles frequently find employment in power distribution systems, wiring conduits, and bus bars. By virtue of being lightweight and cost-effective, they present a favorable solution for electrical installations. Moreover, aluminum profiles exhibit commendable thermal conductivity, successfully aiding in the dissipation of heat emitted by electrical components. Nevertheless, it remains crucial to duly factor in the specific requirements of the electrical application at hand, ensuring that the aluminum profiles adhere to the requisite electrical safety standards and regulations.

- Q: Can recycled aluminum be utilized in construction projects as an alternative to new, raw materials?

- <p>Yes, recycled aluminum can be used in building projects as an alternative to new raw materials. It is not only cost-effective but also environmentally friendly, reducing the energy required for production and the amount of waste sent to landfills. Recycled aluminum maintains the same strength and durability as new aluminum, making it suitable for various construction applications. However, it's important to ensure that the recycled aluminum meets the necessary quality standards and specifications for your project to avoid any structural or safety issues.</p>

Send your message to us

Bosch Profiles Aluminum A380 High Quality Die Cast

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords