BOPP Packaging Tape Factory Aluminum Foil Tape for HVAC System Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

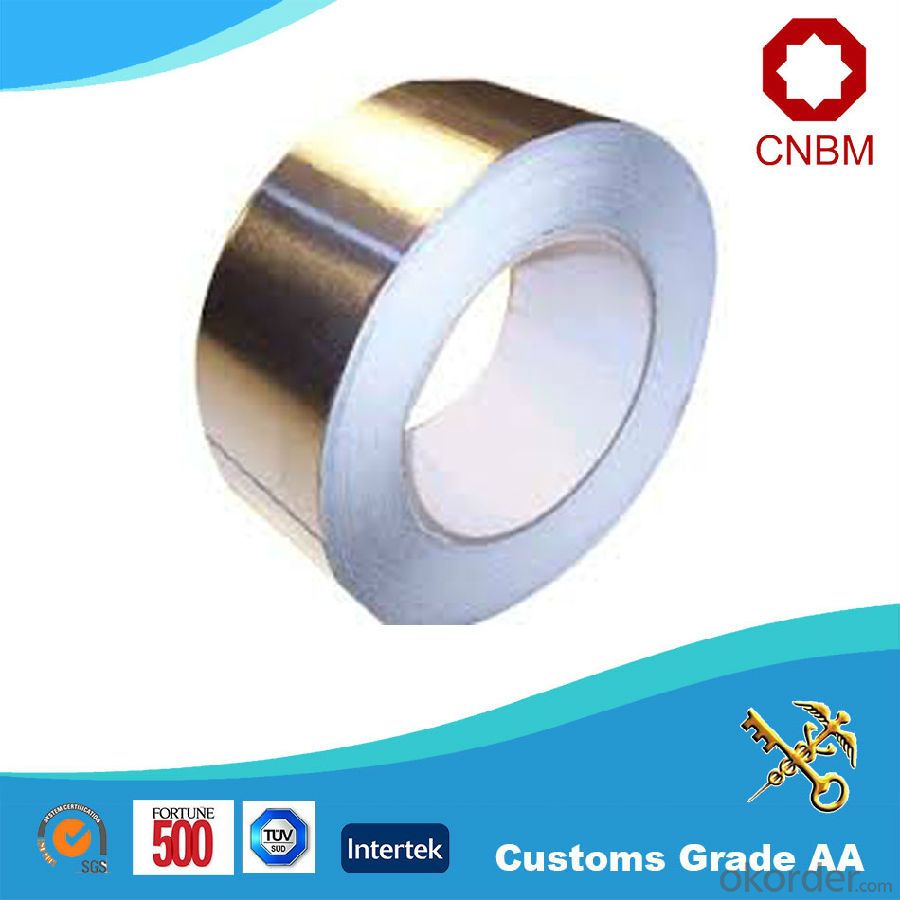

Aluminum Foil Tape for HVAC System Hot Sales

Product Description

Aluminum Foil Tape is suitable in electronic and refrigeration fields due to its excellent thermal and electrical conductivity. Adhesive is solvent acrylic or water acrylic, synthetic rubber and material is aluminum foil.

Functions

A nominal silicone release coated aluminum foil backing, combined with a high performance rubber resin adhesive. Aluminum Foil Tape Without Liner makes easy application.

Aluminum backing provides excellent reflection of both heat and light.

High quality adhesive with strong adhesion and holding power offers permanent sealing and bonding on Foil-Scrim-Kraft Facing joints and seams in HVAC ductwork application.

Good aging resistance both indoors and outdoors.

Low moisture vapor transmission rate offers excellent sealing and patching performance.

Data Sheet

Item | Aluminum Foil Tape |

Thickness (micron) | 22 |

Peel Adhesion (N/25mm) | 18 |

Tensile Strength(N/25mm) | 40 |

Service Temperature (℃) | -20 - +80 |

Elongation (%) | 3 |

Packing | Rolls in Carton |

Certification | SGS and ISO9001 |

Production Line and Tests

Company

As World Top 500 Company, CNBM Internaitonal Corp has 20 Years Experience and make USD1.6 billion yearly sales. We use our high quality and excellent after sales service to earn the clients from 160 countries. We can do OEM service, supported by strong R&D team.

FAQ

1. What is Application?

Aluminum Foil Tape is ideal for: seaming and joint bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

2. More data about this product:

Adhesive: solvent acrylic or water acrylic, synthetic rubber

Aluminum foil thickness: 15/18/22/25/30/35/40/50microns.

protected by an easy-release silicone release paper

3. Are we producer?

We are very professional in supplying aluminum foil tape.

4. Free Samples?

Yes, we would like sending free aluminum foil tape for you.

5. What are other tapes?

Cloth Tape: widely used for wrapping various material products etc.

PVC Tape: used for electrical application, floor marking and pipe wrapping.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape is generally not recommended for use on delicate surfaces or materials. It is designed to provide a strong and secure bond on sturdy surfaces such as cardboard boxes. Using packaging tape on delicate materials may cause damage, leave residue, or negatively affect the appearance of the surface. It is advisable to use specialized tapes or alternative methods to protect delicate surfaces during packaging.

- Q: Can packaging tape be used for mailing packages?

- Yes, packaging tape can definitely be used for mailing packages. It is specifically designed to securely seal packages and ensure they stay intact during transit. Packaging tape is strong and durable, making it ideal for securing boxes, envelopes, or other types of packaging materials. It is commonly used in shipping and mailing applications and is available in various sizes and strengths to accommodate different package sizes and weights. Whether you are sending a small envelope or a large box, packaging tape is an essential tool to ensure your package is properly sealed and protected during the mailing process.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Yes, packaging tape can be used for sealing packages with irregular shapes. Packaging tape is designed to be flexible and adhesive, making it suitable for securing packages of various shapes and sizes. Its strong adhesive properties enable it to stick to different surfaces, including irregular or uneven surfaces, ensuring that the package remains securely sealed during transit. Additionally, packaging tape is typically durable and tear-resistant, providing an extra layer of protection for the package. Therefore, whether the package has irregular shapes or not, packaging tape is an effective and reliable option for sealing it securely.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q: How does packaging tape perform on recycled or eco-friendly packaging materials?

- Packaging tape generally performs well on recycled or eco-friendly packaging materials. The effectiveness of the tape will ultimately depend on the specific type of material being used. Recycled packaging materials, such as cardboard or paper, typically have a rougher surface compared to traditional packaging materials. However, packaging tape is designed to adhere to various surfaces, including those with different textures. Therefore, it should stick well to recycled materials without any major issues. Eco-friendly packaging materials, such as biodegradable or compostable plastics, may have slightly different properties compared to traditional plastics. However, most packaging tapes are designed to work with different types of plastics, including eco-friendly options. It is important to ensure that the packaging tape you choose is compatible with the specific eco-friendly material you are using. In general, packaging tape is designed to provide a secure and reliable seal on packaging materials, regardless of whether they are recycled or eco-friendly. However, it is always recommended to test the tape on a small area of the material before applying it to the entire package to ensure proper adhesion and compatibility.

- Q: How do I prevent packaging tape from getting tangled?

- Here are several suggestions to prevent packaging tape from becoming tangled: 1. Invest in a tape dispenser designed specifically for packaging tape. This dispenser incorporates a built-in cutting blade and roller mechanism that will help maintain control over the tape and prevent tangling. 2. Before applying the tape, ensure that the surface is clean and free of dust, debris, or any other potential obstructions that could cause the tape to stick and tangle. 3. Minimize handling of the tape as much as possible, as each time it is touched, there is a greater likelihood of it twisting or tangling. Handle the tape only when necessary. 4. Use a sharp cutter or a dispenser with a cutting blade to make clean and straight cuts. Uneven or jagged cuts can cause the tape to twist or tangle as it is unrolled or applied. 5. Store the tape properly when it is not in use. Keep it in a cool and dry place, away from direct sunlight or extreme temperatures. Additionally, keeping the tape in its original packaging or a designated container can help prevent tangling. 6. When unrolling the tape, hold the roll firmly and apply a slight tension to keep it straight. Avoid jerky movements or pulling the tape too forcefully, as this can cause it to twist or tangle. By following these suggestions, you can reduce the likelihood of packaging tape becoming tangled, resulting in a smoother and more efficient packaging process.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Yes, packaging tape is generally easy to remove without damaging surfaces. It is designed to adhere securely to packages, but also to be easily peeled off without leaving residue or causing damage to most surfaces.

- Q: Can packaging tape be used for sealing food containers?

- No, packaging tape should not be used for sealing food containers as it is not food-safe and may contain harmful chemicals that can contaminate the food. It is recommended to use food-grade sealing options specifically designed for food containers.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

Send your message to us

BOPP Packaging Tape Factory Aluminum Foil Tape for HVAC System Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 3000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords