6 Wide Masking Tape Red Color Rubber Adhesive 150 Micron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

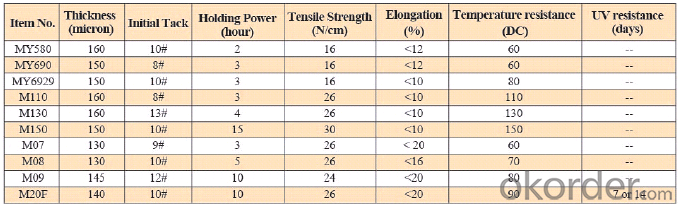

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1800mm; width according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Does packaging tape have a specific weight capacity?

- Yes, packaging tape generally does not have a specific weight capacity as it is primarily used for sealing and securing packages rather than providing structural support.

- Q: Can packaging tape be used for repairing torn paper?

- No, packaging tape is not suitable for repairing torn paper. Packaging tape is designed for securing and sealing boxes and packages, and its adhesive is very strong and may cause further damage to the torn paper. Instead, it is recommended to use a specialized paper repair tape or adhesive, which is specifically designed for repairing torn paper. These tapes are typically acid-free and have a gentle adhesive that is safe for use on delicate papers. Using the right tools and materials will ensure a proper and long-lasting repair without causing further damage to the torn paper.

- Q: Are there any special considerations when using packaging tape for fragile items?

- Yes, there are definitely special considerations when using packaging tape for fragile items. When packaging fragile items, it is important to choose a tape specifically designed for this purpose. Look for packaging tape that is labeled as "fragile" or "handle with care" as these tapes are usually reinforced with additional strength and have special features to protect fragile items. Here are some specific considerations when using packaging tape for fragile items: 1. Strength and durability: Fragile items require extra protection, so it is crucial to use a tape that is strong and durable. Look for packaging tape that is made from high-quality materials, such as reinforced fiberglass or heavy-duty polypropylene, to ensure it can withstand the weight and pressure without tearing or breaking. 2. Cushioning and padding: Fragile items are prone to damage from impact, so it is recommended to use packaging tape that provides cushioning or padding. Some tapes come with built-in bubble wrap or foam padding, which helps absorb shocks and protect delicate items from breaking during transit or handling. 3. Adhesive quality: The adhesive quality of the packaging tape is another important consideration. Fragile items might require longer transit times, and the tape needs to stay securely in place throughout the journey. Look for packaging tape with a strong adhesive that can adhere well to various surfaces, including cardboard boxes, plastics, or glass. 4. Easy removal: Fragile items often need to be unpacked delicately, so it is essential to use packaging tape that can be easily removed without leaving any sticky residue or damaging the item. Some tapes are designed to have a low-tack adhesive, making them easier to peel off without any hassle. 5. Clear visibility: It is crucial to ensure that fragile items are clearly marked to alert handlers and delivery personnel. Using packaging tape that is brightly colored or labeled with a "fragile" message can help draw attention and promote careful handling. In summary, when using packaging tape for fragile items, it is essential to choose a tape that is strong, durable, provides cushioning, has a high-quality adhesive, and is easy to remove. These considerations will help protect fragile items from damage during shipping or handling.

- Q: How does packaging tape perform when exposed to sunlight?

- Packaging tape typically performs well when exposed to sunlight, especially if it is made from durable materials like acrylic or polypropylene. These tapes are designed to resist UV rays and maintain their adhesive properties even when exposed to sunlight for extended periods. However, it is always recommended to check the specifications of the specific tape you are using, as some may have limitations or may be prone to deterioration or discoloration when exposed to direct sunlight for prolonged periods.

- Q: Can packaging tape be used for sealing plastic shoeboxes?

- Indeed, plastic shoeboxes can be securely sealed using packaging tape. Crafted to deliver a robust and reliable seal on a multitude of surfaces, including plastic, packaging tape is widely employed for sealing cardboard boxes during shipping and packaging endeavors. However, its effectiveness extends beyond cardboard, making it an excellent choice for sealing plastic shoeboxes. The adhesive on packaging tape possesses remarkable strength, guaranteeing an enduring seal that safeguards the contents within the shoeboxes, effectively warding off any potential intrusion of dust, dirt, or moisture.

- Q: How do I seal a package securely with packaging tape?

- To seal a package securely with packaging tape, follow these steps: 1. Start by ensuring that the items inside the package are properly arranged and secured. 2. Cut a piece of packaging tape slightly longer than the width of the box. 3. Place the tape across the center of the box, ensuring it covers the flaps and overlaps on both sides. 4. Firmly press down on the tape to ensure it adheres properly to the surface. 5. Repeat this process with additional strips of tape, placing them parallel to the first strip and overlapping them slightly. 6. For added security, place strips of tape diagonally across the top and bottom flaps, creating an "X" pattern. 7. Apply pressure to the entire length of each strip to ensure a strong bond with the surface. 8. Finally, test the seal by gently tugging at the tape to ensure it holds firmly. By following these steps, you can seal your package securely with packaging tape, minimizing the risk of damage during transit.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: Can packaging tape be used for sealing wooden furniture?

- Yes, packaging tape can be used for sealing wooden furniture, but it is not the most suitable option. Packaging tape is not specifically designed for sealing wood and may not provide a long-lasting or aesthetically pleasing seal. It is recommended to use appropriate wood sealants or adhesives specifically made for wooden surfaces for better results.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials. While it may not be as durable or strong as specialized construction tapes, packaging tape can still provide a temporary or quick solution for sealing materials such as cardboard, plastic sheets, or lightweight panels. It can be used to secure temporary covers, attach protective layers, or hold materials in place during construction or renovation projects. However, for long-term or heavy-duty applications, it is recommended to use tapes specifically designed for construction purposes, as they are more resistant to weather, UV rays, and have stronger adhesive properties.

- Q: How does packaging tape perform in extreme weather conditions?

- Packaging tape is designed to retain its performance even in the harshest weather conditions. Typically crafted from durable materials like polypropylene or reinforced paper, it boasts resistance to moisture, heat, and cold. During scorching weather, packaging tape remains stable and steadfast, refusing to melt or lose its adhesion. Its adhesive properties are specifically formulated to endure high temperatures, providing a firm grip on any surface it is applied to. By doing so, it effectively prevents packages from opening or sustaining damage during transportation or storage. Similarly, in freezing conditions, packaging tape maintains its flexibility and avoids becoming brittle. Its adhesive strength remains intact, enabling it to adhere to a variety of surfaces even when faced with freezing temperatures. This is crucial in ensuring that packages stay securely sealed and safeguarded against any external elements. Furthermore, packaging tapes frequently possess UV resistance, allowing them to withstand extended exposure to the sun without deterioration or discoloration. This proves highly advantageous for packages stored or transported outdoors, as the tape remains structurally sound and continues to provide a robust seal. In conclusion, packaging tape is meticulously engineered to excel in extreme weather conditions. It offers durability, resilience, and dependable adhesion, guaranteeing that packages remain securely sealed and protected, irrespective of the temperature or weather conditions they encounter.

Send your message to us

6 Wide Masking Tape Red Color Rubber Adhesive 150 Micron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches