Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Blue Coated Aluminium Foils Used for Insulated Panels

We specialize in Blue Coated Aluminium Foils Used for Insulated Panels . Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Blue Coated Aluminium Foils Used for Insulated Panels

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

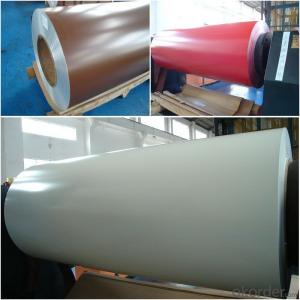

3. Blue Coated Aluminium Foils Used for Insulated Panels Images

4.Specification of Blue Coated Aluminium Foils Used for Insulated Panels

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What do the two items (COIL:873347 HEAT: number) on the label of the raw material of aluminum coil stand for?

- COIL means aluminum coil and HEAT means heating, so together they mean hot rolled coil.

- Q: Are aluminum coils suitable for architectural facades?

- Architectural facades can benefit from the use of aluminum coils. This material is favored for its many advantages. Firstly, aluminum's lightweight nature makes it easy to handle and install, especially for complex architectural designs or tall buildings. Secondly, aluminum is highly durable and resistant to corrosion. It naturally resists rust and does not need additional treatments or coatings. This makes aluminum coils suitable for long-term use in various weather conditions, such as coastal areas or harsh climates where corrosion is a concern. Moreover, aluminum coils offer versatility in terms of design and customization. They can be easily shaped into different sizes, profiles, and forms, allowing architects and designers to create unique facades that meet their specific requirements. Aluminum can also be painted or coated in various colors and finishes to achieve the desired aesthetic appeal. In addition to its functional and aesthetic advantages, aluminum is also an environmentally friendly choice. It is a recyclable material, meaning it can be reused endlessly without losing its properties. This makes aluminum coils a sustainable option for architectural facades, aligning with the increasing emphasis on green building practices. Overall, due to their lightweight nature, durability, versatility, and sustainability, aluminum coils are a suitable choice for architectural facades. They offer a wide range of design possibilities while ensuring long-term performance and minimal maintenance requirements.

- Q: Are there any limitations to the coil weight of aluminum coils?

- The coil weight of aluminum coils is subject to limitations. The primary factor that restricts the coil weight is the capacity of the equipment used for handling and transporting the coils. Different machinery and materials handling systems have varying weight capacities. Exceeding these capacities can result in safety hazards and equipment damage. Furthermore, the size and dimensions of the coils also affect the maximum weight limit. Larger coils generally have a higher weight limit because they possess a larger surface area to distribute the load. Nonetheless, regardless of coil size, there is a practical limit to the weight that the machinery and equipment can bear. Additionally, the coil weight limit is influenced by the strength and integrity of the material used. Aluminum, being a lightweight material with a high strength-to-weight ratio, allows for larger coil weights compared to other materials. However, excessive weight may cause deformation or damage to the coil, impacting its quality and usability. It is essential to take these limitations into consideration and adhere to the manufacturer's recommendations and industry standards when determining the maximum coil weight. Following proper handling, storage, and transportation procedures is crucial to ensure the safety of personnel and the integrity of the aluminum coils.

- Q: Are there any restrictions on the coil length of aluminum coils?

- Yes, there are restrictions on the coil length of aluminum coils. The maximum coil length is typically determined by the capabilities of the equipment used for coil production and handling. Factors such as the size and capacity of coil winding machines, transportation and storage limitations, and the weight and stability of the coil itself all play a role in determining the maximum coil length. Additionally, longer coils may be more prone to handling and logistical issues, such as increased risk of damage during transportation or difficulties in uncoiling and processing. Therefore, it is important to consider these restrictions and limitations when determining the appropriate coil length for aluminum coils.

- Q: What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, soldering, and adhesive bonding.

- Q: Is it possible to utilize an electric iron that features an aluminum coil heater?

- <p>Yes, you can use an electric iron with an aluminum coil heater. Aluminum coil heaters are commonly used in electric irons due to their excellent heat conductivity and quick heat-up time. They distribute heat evenly and maintain a consistent temperature, making them ideal for ironing. However, it's important to follow the manufacturer's guidelines for use and maintenance to ensure safety and longevity of the iron.</p>

- Q: Is it possible to utilize a band saw for cutting an aluminum coil?

- <p>Yes, you can use a band saw to cut an aluminum coil. Band saws are versatile and can cut a variety of materials, including aluminum. However, it's crucial to use the right blade designed for metal cutting. Ensure the blade is sharp and has the appropriate teeth pitch for aluminum to avoid damaging the material or the blade. Adjust the speed to a lower setting to prevent overheating and ensure a clean cut. Always follow safety precautions and wear protective gear when operating power tools.</p>

- Q: Does anyone know if aluminum skateboards are good?

- I haven't seen one since the old QuickSilver-Silver Surfer(circa 1979). They look great, but they become useless when scratched. Which means....you can't really use them for anything. They're not as flexible as wood....and.......Wait until you get hit in the shin with an aluminum skateboard. Aircraft metal my(explicative deleted). My guess is they're inexpensive because they're trying to get the word out. The company owners probably no very little about skateboarding.

- Q: Is it possible to utilize a grinder to smooth out or remove a damaged area on a steel coil?

- <p>Yes, you can use a grinder to grind down a damaged section of a steel coil. However, it's crucial to use the appropriate type of grinder designed for metalworking and to ensure safety precautions are taken, such as wearing protective gear. The grinder should be capable of handling the hardness of the steel and should be operated by someone experienced with such equipment. Always follow the manufacturer's guidelines and safety standards to prevent accidents and ensure the effectiveness of the grinding process.</p>

- Q: This question asks for criteria or methods to determine if a used aluminum coil is safe for reuse.

- <p>To determine if a used aluminum coil is safe to use, consider the following: Check for any visible signs of damage such as cracks, dents, or corrosion. Ensure the coil has been properly cleaned and sanitized to remove any residues or contaminants. Verify that the coil has not exceeded its recommended lifespan or usage limits. Consult the manufacturer's guidelines for any specific safety checks or maintenance requirements. If in doubt, it's best to consult with a professional or replace the coil to avoid potential safety hazards.</p>

Send your message to us

Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords