Thickest Aluminum Foil for Pre-Insulated Insulated Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

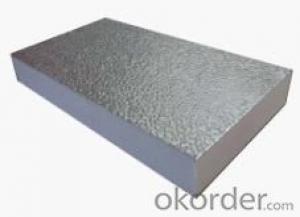

Plain Foil for Pre-Insulated Insulated Panel

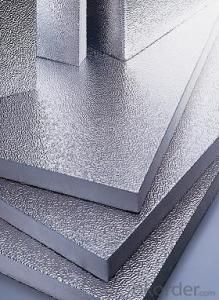

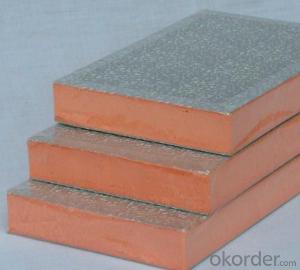

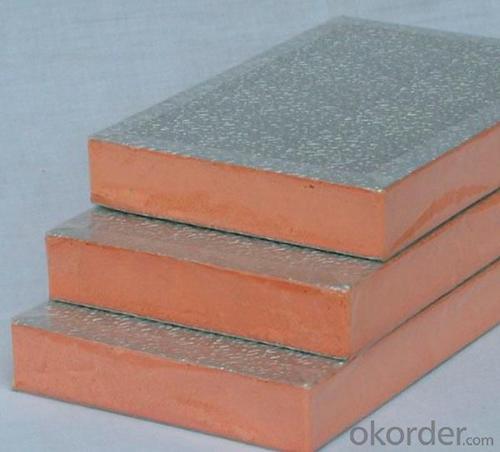

1.Structure of Plain Foil for Pre-Insulated Insulated Panel

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Plain Foil for Pre-Insulated Insulated Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3.Plain Foil for Pre-Insulated Insulated Panel Images

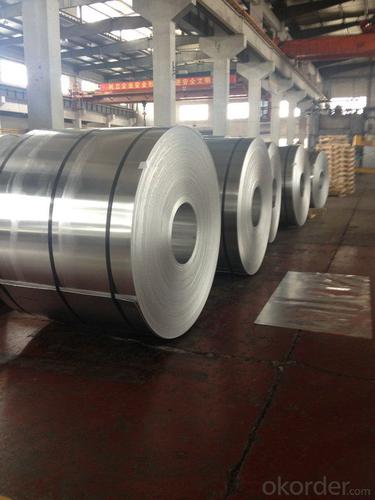

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Plain Foil for Pre-Insulated Insulated Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q: Is the soundproof cotton with aluminium foil good or without aluminium foil?

- The foil is insulated, without it.Under the shield of common pure city road to go, are always suet asphalt road, unless the engine can hit the underpinning, sinking impact is not bad that a thin iron plate.

- Q: is it possible to store first morning urine for about an hour before test?? my period is due tomorrow and i have all teh period-like symptoms that i normally have.this cycle i decided not to quot;tryquot; and let things be.i decided to test on the day of the period(if the period doesnt show) because early testing increases hopes and disappointments.Thats y i didnt buy any ept's at all because knowing me,i would've started testing 1dpo!!!.so i will have to go and buy one tomorrow morning.can i store the first morning pee in a cup covered with aluminum foil?

- maximum drugs have an expiry date for a reason.Are you unable to bypass to the scientific expert to have a sparkling prescription made out, if so bypass to your close by chemist or have somebody decide for you and ask them for an around the counter drugs of comparable intensity.

- Q: My friend from the UK always talks about craving brownies, so I want to surprise her by sending some! The shipping would take 3-5 days, how would I package them? Thanks :3

- they use a man/crane called a cherry picker'

- Q: the superglue is dry n hard.

- leave the old and blo in at least 8 in.,,inst ridge vents if u have soffit vents,,if no soffit vents then a power vent

- Q: I built it with 3 cards ( the ones used to play go fish ) and 2 pieces of aluminium.They are in this order card, foil, card, foil, and card.They are sandwitched together and the foil isn't glued it's taped with duct tape.I connected a wire to each piece of foil and then to a battery.Left it there for 2 minand took the battery off .WITHOUT TOUCHING the wires.THEN.I tuched the wires without the batand didn't feel anything.What's wrong?At this point anything will help :-(-)-(

- it can be done but is hard to do right.just fork out the money and buy a kn cold air intake they are the best from what i have seen

- Q: I got a fried haddock sandwich at a restaurant earlier today, I didn't end up eating it, so I brought it home and put it in the fridgeI wanna warm it up now, but my microwave isn't working, and my oven is the only way I can warm it upCan someone tell me the best way I can do it? Should I wrap it in aluminum foil? what temp, and how long? Please someone answer- I'm starving now-lol

- How experienced are you at knitting? in case you may seem on the kind of the finished effect and wing it, then with this style of undertaking you're waiting to flee with itit really is going to likely be very fiddly - have you ever knitted any small toys earlier? may be an concept to stay with some knitted toy kinds first, earlier attempting to remodel from crochetCrochet and knitting typically variety in texture, no longer purely names of stitchesyou may want to do something truly dense, egmoss stitch, to get a similar effectsturdy luck!

- Q: quot;320g of hot H20 at 80 degree celcius is poured into an aluminum can of mass 35 g and temperature of 20 degree celcius Calculate the final temperature.quot;Okay , first of all , I don't really get the question , or more exactly , I do not know what it actually want Calculate the final temperature for what? water? or can? I understood clearly the formula which is Heat Supplied(?)Q m.c.deltaTeta/Temperature , the problem is how am I supposed to applied it on this 'not so professional question'? .please teach me and give me some explanation! I bid you and awesome advance thanks!

- C4, be careful with that stuff

- Q: for mini pies? flour ? oil ? i don't have any parchment paper so i need another substitute.

- oil the pan OR use aluminum foil

- Q: to get marijuana taste out of a tobacco (wooden) pipe? My amazing, wonderful (/sarcasm) ex-roommate took my $80 Savanelli pipe and smoked weed out of it, ruining the taste.Any suggestions at all welcome.

- well, sucking on cancer sticks is a biggie, and so is excessive drinking.Her BMI isn't in great shape eitherForm a pact and walk 30 minutes a day,that is AMAZING for your whole bodyTry to stay away from junk food in general and sodaThere's tons of alternatives or healthy versions of her favorite junk food I'm sureGo on this journey with her! It makes it more likely for her to stick to it if she has someone going thru it with herGood Luck!!

Send your message to us

Thickest Aluminum Foil for Pre-Insulated Insulated Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords