Black Treadmill PVC Conveyor Belt Black Fitness belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Black Treadmill PVC Conveyor Belt,Black belt,Fitness belt

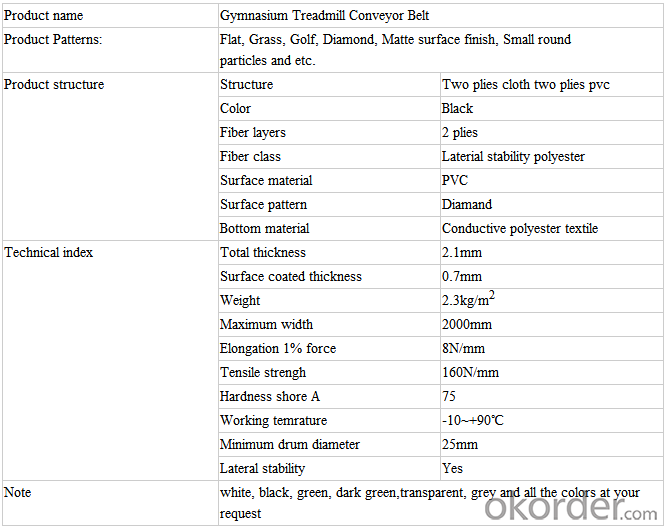

1.Product Description:

Our Treadmill conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Easy setting and cleaning, Competitive price and high quality.Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant.

They have different thickness, different patterns, antistatic coating compounds, low noise, long life, high precision, which makes the belts on the treadmill work smoothly and a comfortable running.

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

2.Product Specification:

3.Product Advantages:

1).Our treadmill conveyor belts need no lubrication and run quietly and smoothly – without noise or tracking problems.

2).Our treadmill conveyor belts combine low energy sonsuption with durability and an excellent appearance

4.Product Feature:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

5.Product Quality Control

We have very strict quality control system to test all the finished conveyor belts to ensure all the products you receivec are of high quality.

6.Packaging & Shipment

Conveyor belts are packed in rolls and covered by poly woven bags. Also, we can pack it according to your requirments.

7.Product Pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Treadmill conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Process for producing rubber products

- In order to adapt to the different conditions of use, to achieve a variety of performance, also in order to improve the performance of rubber products and reduce the cost must be added with different chemicals in raw. Mixing is the mixing of raw rubber and compound mixing, placed in the mixing machine by mechanical mixing with the role of agent, uniformly dispersed in rubber in a process. Mixing is an important process in the production of rubber products. If the mixture is uneven, it can not give full play to the role of rubber and mixture, and affect the performance of products. People get glue mixing after the production of various rubber products for mixing it is semi-finished materials, rubber products, commonly known as the glue are usually sold as a commodity buyers can directly process material, need to use the rubber vulcanization. According to the formula, a series of different grades and varieties with different performances are selected.

- Q: Why should the tire be made of rubber?

- Rubber not only has excellent wear resistance, long service life, but also has good elasticity. As a tire, it can absorb a lot of vibration energy, which is conducive to the smooth running of the car. So rubber will be used as a tyre for cars.

- Q: How to distinguish between good and bad silicone rubber gasket?

- When the silica gel products are subjected to alternating stress (or strain), the structure and properties of the material change. With the development of fatigue process, the failure of silica gel products is called fatigue damage. Therefore, fatigue is also a way to distinguish the quality of silicone products.

- Q: What are the rubber parts for the car?

- Sealing ring, toothed cutting belt, automobile synchronous belt, automobile multi wedge belt, automobile engine suspension rubber pad, shock absorber glue, anti-collision shock absorption rubber, dustproof cover, fuel tank cover, filter rubber parts, cloth (diaphragm)

- Q: What are the ingredients in the tires?

- Tires are usually composed of 3 parts of tyre, tyre, cushion belt. The inner layer of the fetus body has the rubber layer with good air tightness, and a special wheel rim is required. The structure of tire in the world has been developed in the direction of tubeless, radial structure, flat (smaller ratio of height to width of tire section) and light weight.

- Q: Can the rubber surface be painted with paint?

- The surface of the rubber is sprayed with paint, and it wants to be covered with black paint, but I don't know the effect of paint on rubber for a long time. Rubber is mixed rubber or rubber paint is used!

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- Rubber has poor elasticity, permanent deformation, large creep, poor deflection and so on.

- Q: What kind of rubber does TPE belong to?

- TPE does not belong to rubber.Although TPE has a tensile resilience similar to that of ordinary rubber, TPE is thermoplastic and rubber is thermosetting. Rubber needs cross-linking. It can not be reprocessed after molding. TPE can be processed repeatedly.

- Q: Is there any poison in the processing and testing of rubber products? What about the salary?

- Rubber products processing and testing of this work has low toxicity, pay attention to ventilation, strengthen physical exercise, no problem!! The salary is average, basically between 2500--3500!

- Q: How to solve the spray of rubber products?

- 1, dry finished products should be packaged sealed, placed in a cool and dry place inventory, avoid sunlightDirect irradiation,2. For the rubber products with the condition of spitting and spitting, the air and temperature at the storage place shall be controlled after the processingDegree and humidity conditions,3, as soon as possible out of storage, not long storage, reduce the aging opportunities of rubber products.

Send your message to us

Black Treadmill PVC Conveyor Belt Black Fitness belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords