Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce Description:

Black Annealed Iron Wire also called galvanized steel wire, galvanized iron wire according to the difference zinc coating process, there are electro galvanized iron wire and hot-dipped galvanized iron wire.

Black Annealed Iron Wire can be classified into hot-dipped galvanized iron wire and electro galvanized wire according to the differences of processing. This wire is very good for Chain link fence, fencing mesh, gabion mesh box production and for construction business as tire wire, binding wire and galvanized wire raw material production.

2.Main Features of Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce :

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

3.Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce Images

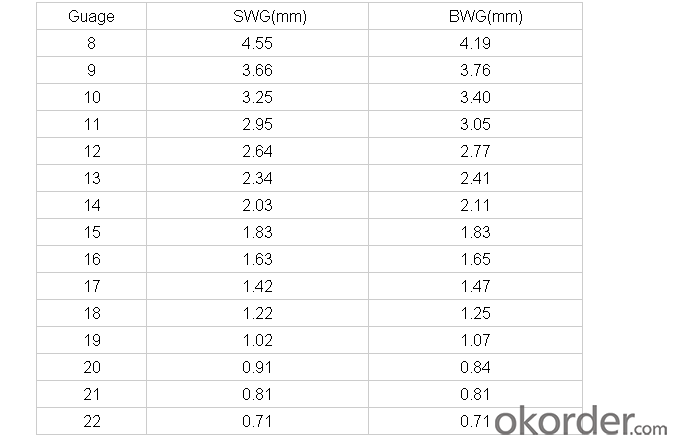

4.Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Black Annealed Iron Wire we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products.

②What is the advantage of our Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce ?

1. Durable service life and competitive price.

2. Beautiful, strong and not expensive.

3. With long live and good anti-corrosive

4. High quality and low price.

③How long can we receive the product after purchase?

In the purchase of Black Annealed Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce

- Q: I have DirectWay and have a wireless router. I recently hardwired my computer in because I kept losing signal. The distance between my computer and the router is about 30 ft. But since I hardwired my computer in, it seems slower than when I ran the wireless adapter, i.e downloading videos and music. I was under the impression that wired was faster. What gives????

- Very unusual for a wired Ethernet connection to be slower than a wireless connection. I would check cabling, also verify that you router is actually routing via NAT, some companies might try to prevent more than one computer from connecting to them without a specific contract, if your router can NAT the address, this will make it seem like you have only one computer connected. The problem is most likely a cabling issue, or misconfiguration on the Network card itself.

- Q: In that chart it has 2 sections, one is maximum amps for chassis wiring and the other is maximum amps for power transmission. What is considered chassis wiring and what is considered power transmission?

- Chassis wiring assumes each wire is routed separately, and power wiring assumes they are wired in a bundle. In chassis wiring the cooling of the conductors is better, because they are all exposed directly to air. In a bundle, some of the wires are not in direct contact withe the air.

- Q: Need wiring diagram or manual

- Here okorder /

- Q: how are lights grounded on a car? Seems like all the wires to the light have electricity running to them.

- Is somebody suppose to know what light you're talking about?

- Q: like in movies how do you connect like some wire to start the car? also which wires? I'm curious not trying to take anyone's car.

- Modern cars cannot be started that away. The older ie 1974 and younger can be.

- Q: I have a 1997 Dodge Neon 2DR and i did a electric door and mirror conversion but i cannt figure out the wiring... how would i go about figuring it out... can some explain or better show me how a basic lock and mirror controls are wired

- i own a repair shop,and if you,ll get a good Haynes repair manual on it,this will have the wiring diagrams in it,for doing this ,that's about the only way you can wire it up right on this job,good luck,i hope this help,s.

- Q: Where, online, can I find a (color!) wiring diagram for my 1985 Yamaha Virago 700?My motorcycle starter solenoid isn't throwing because the little wire isn't getting connected to negative -- it might be a connection to the handlebar starter switch, or the quot;run/offswitch, or the side stand sensor, or the neutral sensor, or something else! I need to see a diagram so I can tell what that something else is, and to see what color the wires from all those other sensors are.

- Wiring okorder

- Q: If you put clay over wire and bake it would the wire melt and ruin the sculpture?Details on wire:I'm not sure what kind of wire it is but it says Bright Floral Wire..Wire is silverDetails on Clay:Again, im not sure what clay...its from polyform products and it says Premo Sculpey so im guessing Polymer? :#92;Clay is Black.Bakes for 275F (130C)30 minutes per/par/por1/4 in (6mm)

- (Premo okorder /

- Q: i need to know if my wires are hooked up right

- Most thermostats have multiple wires because they can be set to control different kinds of systems. Check the manual to see which connections you need for your situation. If it can turn on your heater (and air conditioner if you have one), then it is connected properly.

- Q: I have just started wire working to make bracelets. I have a few questions. 1, is there a place where I can buy thick wire (16 to 18 gauge) in bulk? The items I am making take about a yard of wire. Considering the only thing I could find was 16 (or slightly hire) gauge in 7 foot increments. For new wire workers, do you have any suggestions on cheap practice materials. Also for those things that don't turn out great, what do you guys do with them?

- For okorder /

Send your message to us

Black Annealed Wire from CNBM SWG 18 and SWG 20 with Low Pirce

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches