Titan Geogrids Bitumen Coated Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

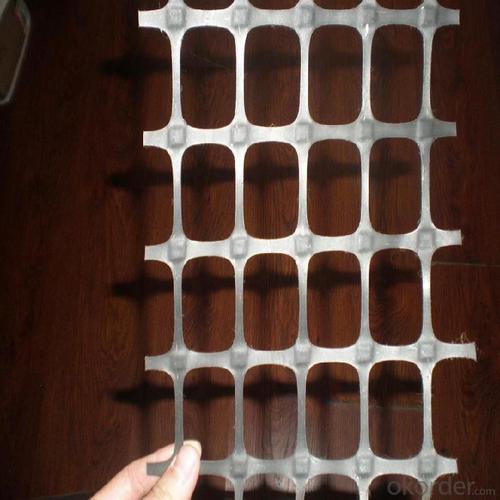

Structure of Bitumen Coated Geogrid

Bitumen Coated Geogrid is to select high quality enhanced non-alkali fiberglass yarn,and it uses foreign advanced warp knitting woven to become the base materials.Using the warp knitting oriented structure to make full use of the fabric yam strength and improve its mechanical properties ,so it makes good tensile strength ,tearing strength and resistance to creep properties of modified asphalt,and through high quality coating is handled and become planar finely materials.

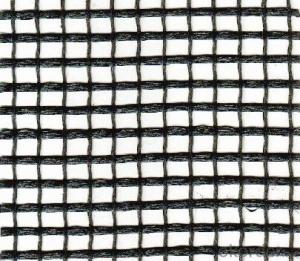

Main Features of the Fiberglass Geogrid

fiberglass geogrids

Corrosion resistance, no long-term creep, long life span.

- Tensile strength:MD/CD:30 ~ 150kn/m.

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Bitumen Coated Geogrid Images

Bitumen Coated Geogrid Specification

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength;

Reinforcement and stabilization of riverside,embankment and side slope;

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

Reinforcement of the surface of road and bridge

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Road extension.

Reinforcement of soft soil foundation and overall strength of roadbed

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Biaxial Plastic Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids resistant to puncture?

- Yes, geogrids are typically resistant to puncture due to their durable construction and materials used. They are designed to withstand various stresses and loads, including sharp objects and heavy loads without getting punctured.

- Q: How much is a glass fiber mesh

- What size, how much, these things are not the same price.

- Q: What is the recommended depth of geogrid installation?

- The recommended depth of geogrid installation can vary depending on the specific project and soil conditions. However, in general, it is recommended to install geogrids at a depth of at least 12 inches to provide adequate stabilization and reinforcement to the soil.

- Q: Can geogrids be used in underground tunnels?

- Yes, geogrids can be used in underground tunnels. Geogrids are commonly used in tunnel construction to reinforce the soil and provide stability to the tunnel walls. They help in preventing soil erosion and maintaining the overall structural integrity of the tunnel.

- Q: Are geogrids resistant to biological fouling?

- Yes, geogrids are generally resistant to biological fouling. Geogrids are made from materials that are not easily degradable, such as high-density polyethylene (HDPE) or polypropylene (PP), which makes them less susceptible to colonization by organisms and reduces the likelihood of biological fouling. Additionally, geogrids often have a smooth surface that makes it difficult for biofilms or other organic matter to adhere to the grid. However, it is important to note that while geogrids are resistant to biological fouling, they are not completely immune, and regular inspection and maintenance may be required to prevent any potential buildup of organic matter.

- Q: Are geogrids resistant to alkali degradation?

- Yes, geogrids are generally resistant to alkali degradation. They are designed to withstand harsh environmental conditions, including exposure to alkaline substances, without significant degradation or loss of strength.

- Q: Are geogrids suitable for reinforcement of airport runways?

- Yes, geogrids are suitable for the reinforcement of airport runways. Geogrids are high-strength materials that can effectively distribute loads and provide stability to the runway surface. They have been extensively used in civil engineering projects, including airport runway construction, to enhance the strength and durability of the pavement structure. Geogrids help to minimize rutting, cracking, and other forms of distress, improving the overall performance and longevity of airport runways.

- Q: What is the meaning of the highway geogrid gsl50/hdpe

- Hi ~ ~ ~ ~ on the high-speed use of geogrid, nothing more than two kinds, a kind of roadbed with geogrid, a kind of pavement with geogrid, you said that GS150 is certainly the roadbed with steel plastic geogrid,

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are commonly used in road construction to reinforce the pavement layers and improve the overall strength and stability of the road. They help to distribute the load more evenly, reduce the potential for cracking and rutting, and enhance the lifespan of the road.

- Q: In the middle of geogrid foundation treatment process is belongs to the concealed work it

- After the completion of the project is not visible to the process or project site, are known as the hidden works, so the geogrid must belong to the hidden works

Send your message to us

Titan Geogrids Bitumen Coated Geogrid for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords