Asphalt Reinforcement Geogrids - Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

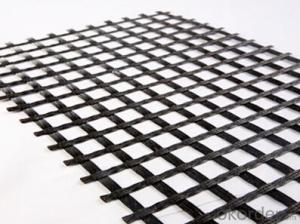

Fiberglass Geogrid with Bitumen Coated for Base Stabilization

Description Of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

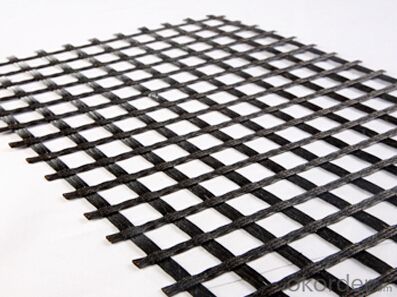

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

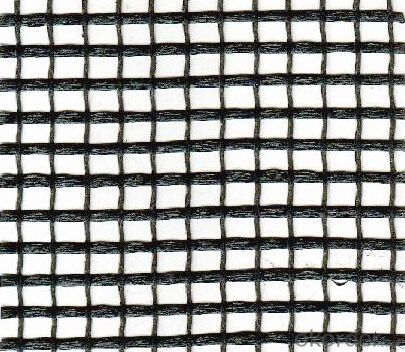

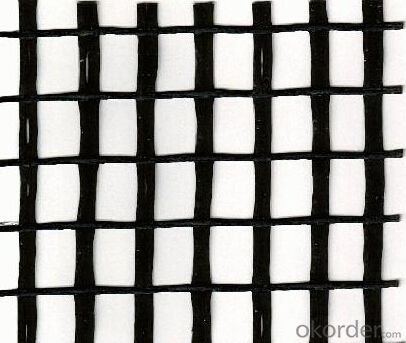

IMages of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

FAQ of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Classification and characteristics of geogrids

- The geogrid is divided into four categories: fiberglass geogrid, steel plastic geogrid, polyester geogrid and plastic geogrid

- Q: Are geogrids suitable for use in permafrost conditions?

- Geogrids are generally not suitable for use in permafrost conditions due to their potential to cause ground disturbance and accelerate thawing of the frozen soil. Permafrost is a delicate and sensitive environment, and any disturbance to its structure can lead to significant damage and instability. Therefore, alternative solutions specifically designed for permafrost conditions should be considered to ensure long-term stability and environmental protection.

- Q: Can geogrids be used in shoreline protection?

- Yes, geogrids can be used in shoreline protection. Geogrids are commonly used to stabilize and reinforce soil, including in coastal areas. They can provide erosion control, improve soil stability, and enhance the overall resilience of shorelines against waves and tidal forces.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in expansive soils?

- Geogrids improve the performance of mechanically stabilized slopes in expansive soils by providing reinforcement and stability to the soil mass. They prevent excessive movement and deformation of the soil, reducing the risk of slope failure and erosion. The geogrids distribute the load applied on the slope more evenly, enhancing its overall strength and preventing the development of cracks and settlements. Additionally, geogrids can control the lateral spreading of expansive soils, minimizing the potential for slope instability.

- Q: What is the recommended depth of geogrid installation?

- The recommended depth of geogrid installation depends on various factors such as soil conditions, load requirements, and project specifications. However, a general guideline is to install geogrids at a depth of at least 12 inches below the surface to ensure sufficient reinforcement and stability.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength and stability. They act as a reinforcement layer within the tube, preventing deformation and maintaining the desired shape. Geogrids also help distribute the load evenly, increasing the overall stability and durability of the geotextile tube system.

- Q: Basic introduction of fiberglass geogrid

- Fiberglass geogrid is glass fiber as the material, the reticular structure material of the knitting process, for the protection of glass fiber, improve the overall performance of geo composites through a special coating treatment process and the.

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. Geogrids are commonly used in civil engineering and construction projects to reinforce soils and provide stability to foundations. They are effective in distributing loads and reducing soil movements, which helps to prevent foundation settlement and improve overall structural integrity.

- Q: Geogrid and geotextile which effect is good

- Geotextile has excellent filtration, isolation, reinforcement and protection effect, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance

- Q: Specifications and parameters of Geotextiles

- Types of geotextiles is various, so the geotextile material in macro Xiangxin staple fiber needle punched geotextile is often said that as an example, introduce the specifications and parameters.

Send your message to us

Asphalt Reinforcement Geogrids - Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords