Bitac Continuous Filament Woven Geotextile - Polyester or Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PET or PET Woven Geotextile

Woven Geotextile Introduction

Woven Geotextile is made of high tenacity and high molecular weight polyester yarns. Wear-resisting, bursting resistant and high tensile strength, also provide different strength at low elongation.

Woven Geotextile Application

Woven geotextile can be applied in soil stabilization, embankment, reinforced wall and slope, sidewalk paver, coastal and riverbank revetments, landfill separators and capping, etc.

Woven Geotextile Advantage

-High tensile strength

-Wear resistant

-Burst resistant

-Easy carry and easy application

Woven Geotextile Specifications

Tensile strength(kN/m) | 100/50 | 200/50 | 400/50 | 600/50 | 800/50 | 1000/50 | 60/60 | 100/100 | 120/120 | 200/200 | 220/220 |

MD Values | 100 | 200 | 400 | 600 | 800 | 1000 | 60 | 100 | 120 | 200 | 220 |

CMD Values | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 100 | 120 | 200 | 220 |

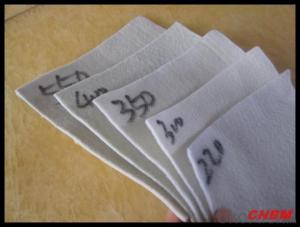

Woven Geotextile photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Of course, or 100 grams of Kazakhstan, the loss can be ignored manufacturers do not produce geotextile geomembrane

- Q: What are the key properties of geotextiles?

- Geotextiles are permeable fabrics that are used in various civil engineering applications. The key properties of geotextiles include their ability to provide filtration, separation, reinforcement, and drainage. They are durable, resistant to biological and chemical degradation, and have high tensile strength. Geotextiles also offer good water permeability, allowing for effective water flow while preventing soil erosion.

- Q: How do geotextiles contribute to soil reinforcement?

- Geotextiles contribute to soil reinforcement by providing a stable and durable layer that helps to distribute loads and reduce soil erosion. They act as a barrier against the movement of soil particles, preventing soil erosion and maintaining the stability of the soil structure. Additionally, geotextiles can improve the tensile strength of the soil, increasing its load-bearing capacity and overall stability.

- Q: What are the applications of geotextiles in civil engineering?

- Geotextiles have a wide range of applications in civil engineering. They are commonly used in road construction, where they provide reinforcement and stabilization to the soil, preventing the formation of cracks and potholes. Geotextiles are also used in the construction of embankments and retaining walls, where they provide erosion control and improve soil stability. Additionally, they are used in drainage systems to filter out fine particles and prevent clogging. Overall, geotextiles play a crucial role in enhancing the performance and durability of various civil engineering structures.

- Q: How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by distributing the load from heavy vehicles or equipment over a larger area, thereby minimizing the pressure exerted on the soil. This prevents the soil particles from being compressed tightly together, allowing for better soil structure and drainage.

- Q: How do geotextiles help with erosion control?

- Geotextiles help with erosion control by providing a protective barrier against soil erosion. They are designed to be permeable, allowing water to pass through while preventing the loss of soil particles. Geotextiles also stabilize soil by increasing its strength and preventing it from being carried away by wind or water. Additionally, these materials promote vegetation growth by retaining moisture and nutrients, further enhancing erosion control efforts.

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Calculate the surface area of the water pipe, and then add a 10% of the amount, is the amount of geotextile, Huazhi geotextile material manufacturers to answer

- Q: How do geotextiles help in the prevention of clogging in drainage systems?

- Geotextiles help prevent clogging in drainage systems by acting as a filter barrier, allowing water to pass through while trapping and preventing the migration of fine particles or soil into the drainage system. This helps maintain the long-term functionality and efficiency of the drainage system by reducing the risk of clogging or blockages.

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: Can geotextiles be used for reinforcement of road embankments?

- Yes, geotextiles can be used for the reinforcement of road embankments. Geotextiles are commonly employed in road construction and maintenance to enhance the stability and durability of embankments. They provide reinforcement by distributing loads and reducing settlement, while also improving drainage and preventing erosion.

Send your message to us

Bitac Continuous Filament Woven Geotextile - Polyester or Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords