Bio Geotextile High Permeability Polyester Spunbond Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Non Woven Polyester Geotextile Description:

Non Woven Polyester Geotextile Made from PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

technical parameter

Test | Unit | Standard/ Guaranted |

Mass per unit area | g/㎡ | 160/152.0 |

thickness | mm | 0.80/0.68~0.92 |

width | m | 3.8 |

Max. Tensile strength (MD) | KN/m | 12/10.2 |

Max. Tensile strength (CD) | KN/m | 11/9.2 |

Elongation at Max. tensile strength (MD) | % | 30.0/25 |

Elongation at Max tensile strength (CD) | % | /35.0/27 |

CBR bursting strength | KN | 1.8/1.5 |

shrinkage(MD) 200℃ | % | ≤1.7 |

shrinkage(CD)200℃ | % | ≤0.1 |

Elongation 3% Tensile strength(MD) | KN/m | 5/4.5 |

Elongation 15%Tensile strength(MD) | KN/m | 9/8.1 |

Elongation 3% Tensile strength(CD) | KN/m | 3.6/3.24 |

Elongation 15%Tensile strength(MD) | KN/m | 6.4/5.76 |

Trapezoid tearing strength | KN | 0.2 |

bitumen oil adsorption | L/㎡ | 0.8-1.2 |

Melting point |

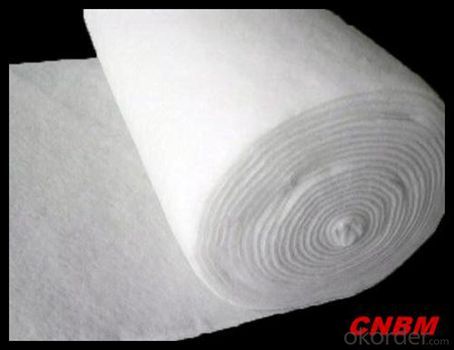

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Product Description:

Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products are set by various organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Geosynthetic Institute (GSI). These standards cover different aspects of geotextile products, including their physical properties, mechanical performance, durability, and installation guidelines. Compliance with these standards ensures that geotextile products meet the necessary requirements for their intended applications and ensure the safety and reliability of their use in civil engineering and environmental projects.

- Q: Can geotextiles be used in the construction of wastewater treatment plants?

- Yes, geotextiles can indeed be used in the construction of wastewater treatment plants. Geotextiles are commonly used in these projects for various purposes such as filtration, separation, erosion control, and reinforcement. They can be applied in different areas including lining of ponds, filtration of effluent, protection of pipes, and stabilization of soil. Geotextiles help enhance the efficiency and longevity of wastewater treatment plants by providing necessary support and functionality.

- Q: Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q: Who knows geotextile, how to sew, the best video

- Where do you use it? Professional production geotextile manufacturers to answer,

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. Geotextiles are often used as a protective layer between the roof membrane and the growing medium or drainage layer in green roof systems. They help prevent clogging, promote water drainage, and provide additional reinforcement to the roof structure.

- Q: What is the role of geotextiles in soil reinforcement?

- The role of geotextiles in soil reinforcement is to provide strength and stability to the soil by enhancing its engineering properties. Geotextiles act as a barrier, separating different soil layers and preventing their mixing, which helps in maintaining the integrity of the soil structure. They also help in distributing loads and reducing the potential for soil erosion. Additionally, geotextiles can improve drainage and filtration characteristics of the soil, ensuring better water movement and preventing the buildup of excess pore pressure. Overall, geotextiles play a crucial role in enhancing the performance and longevity of soil structures.

- Q: What are the fire resistance properties of geotextiles?

- Geotextiles typically have low to moderate fire resistance properties. While they are not inherently fireproof, some geotextiles are manufactured with fire-retardant additives or coatings to enhance their resistance to flames and heat. However, it is important to note that the fire resistance of geotextiles can vary depending on the specific type and composition of the material.

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil slopes when used in conjunction with geogrids. They help to distribute loads, reduce soil erosion, and improve drainage, which ultimately enhances the performance and longevity of the reinforced slope system.

- Q: Geotextile moisture-proof layer: 200 cloth +400 film +200 cloth

- Two cloth a film manufacturers direct production qualification need to contact

- Q: Can geotextiles be used in erosion control in river channel stabilization?

- Yes, geotextiles can be used in erosion control in river channel stabilization. Geotextiles are engineered fabrics that can be placed in river channels to prevent soil erosion and stabilize the riverbanks. They help in reducing the velocity of water flow, trapping sediment, and promoting vegetation growth, thereby effectively controlling erosion in river channels.

Send your message to us

Bio Geotextile High Permeability Polyester Spunbond Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords