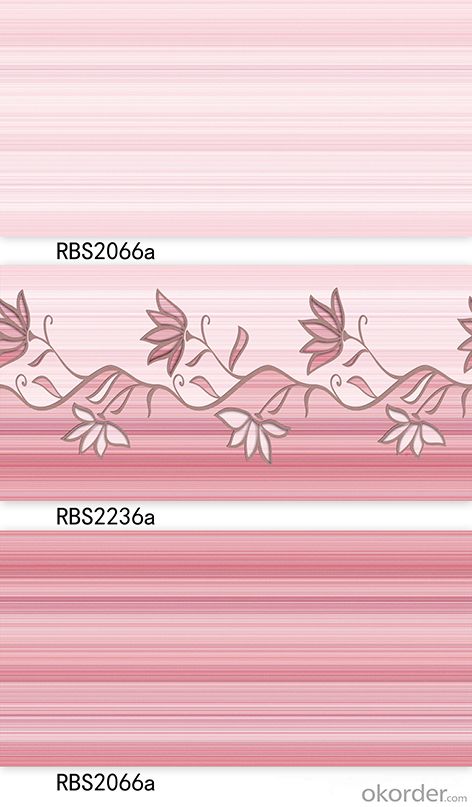

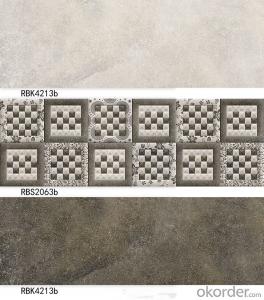

Best selling ceramic wall tiles in Dubai market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Best selling ceramic wall tiles in Dubai market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

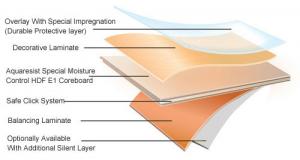

- Q: Veneer wood floor?It's a dish bean

- And laminate flooring? Solid wood is immune through stickers and molded floor, so expensive. Surface stickers are laminate flooring.

- Q: I live in a condo apartment on the 2nd floor. I want to soundproof the floor, but I don't want carpeting. Therefore, I glued a cork underlayment to a wood sub floor. Now, I want to glue the engineered wood floor to the cork underlayment. Is this reccomended?

- If your cork is down well and the glue you use will bond to the cork, your ok. Check out what type of glue your using. Most urethane based glues will work. GL

- Q: The solid wood floor in the floor, gold plate, solid wood composite floor of the difference between the three and characteristics'cause I'm gonna mess this upThank you can help

- Real wood floor is natural wood, green Jiankang, wood flooring is the wood slice pressing, not afraid of water environmental protection, gold plate heard

- Q: All my boards are in 3ft lengths. Do I need to cut them to various lengths before starting? What lengths should I cut them in? Does it look weird having a 3ft borad then a 8 inch board? Please help!

- If you don't want glue(Chemicals,formaldehyde)in the house you can use a rubber membrane on top of the concrete beneath the wood. It will give you a more solid floor than just floating it.Home depot has a product its a green roll membrane.

- Q: Would like to shop in the solid wood flooring directly on the floor, ask experienced friends, so what is the problem

- In fact, the solid wood floor can be refurbished, as long as the demolition of the bad part of the re installation, and then the overall grinding, scraping putty seam, brush floor paint protection. To do so out of the floor and even some aspects take on an altogether new aspect, but also better than the new floor, which is an overall effect, put on the edge of the elastic rubber seal, the floor even afraid of water. But also to avoid the pollution of paint, had to use expensive water-based floor paint

- Q: Solid wood flooring with laminate flooring, which is better

- 1, comfort contrastParquet wood flooring inherited the elegant natural, comfortable, good insulation properties, strengthen the floor because of its texture density, Juegan good will.

- Q: I would like to ask the solid wood floor can bask in the sun? My home is very abundant sunshine, the basic drying day

- If you feel your sun is very sinister, it is recommended that the curtains! If it is not very toxic, it is recommended that the sun is better, so that the house will not be wet.

- Q: Can anybody tell me some difference between hardwood floors and engineered floors?

- Solid Wood: today most people consider solid logs cut to size and finished with a Tongue & a groove to be Real wood usually at least 3 wide & at least 3/8 thick. sizes bigger that 4 are called planks & thicknesses from 5/8 up to 1 1/4 are all common & readily available. Almost all solid wood floors require nailing to keep the wood in place ad they are still very susceptible to swelling in the wet & heat & shrinking apart in the cool & the dry. Engineered Wood: Looks like Plywood (it's NOT) with one side finished with a high quality species & a great factory applied finish and or stain. The engineered wood starts with anywhere from 3-10 layers of veneer glued together under very high heat & pressure. The top layer is usually the most premium of all the veneers & is often thicker than all the rest. The veneer, boards are referred to as engineered, since they are man made and built for a specific purpose, like flooring. Engineered wood is actually harder, stronger & much more stable than the same thickness of solid wood. It can also be glued down in areas where nailing is not possible like slab floors & basements. Engineered wood also resists swelling & bowing, because the layers are rotated in different directions as the boards are laid up before they are heated & pressed together. Environmentally the engineered wood uses less wood & the veneering process leaves almost no wasted wood and no sawdust. Once its on the floor even most experts cant tell the difference & the price is about the same for a good solid or a top of the line engineered. Save the money, the swelling & cracking and the forest & go with the engineered if you find a color or style that you like.

- Q: Advantages and disadvantages of solid wood flooring

- Stability: solid wood floor of its wood fiber unidirectional and tree core and tree edge of the tree age is different, resulting in different levels of wood density of wood, so the plate caused by the thermal expansion coefficient is different and easy to deformation. In the case of dehydration easy to sew. Strengthen the production process of the floor is wood waste processing into powder, add glue, pressed into high density plate under high temperature and pressure, and then paste the computer printing decorative paper, then coated with three two aluminum oxide coatings and wear resistant materials, finally processed into what we see shape. Strengthening plate stability is good, but because of its substrate is high density board, heat and moisture to the whole swell, if left in the installation of the contraction joints of small, easily arching, and the floor is afraid of water, water easily after expansion, not a good deal. Multi layer solid wood floor, the production process is to cut wood veneer, and then according to the wood grain crisscross with resin glue hot pressing molding. Because the structure is arranged in a crisscross pattern characteristics between the layers contain each other, so as to overcome the above wood heat expansion coefficient of eighty-five percent, the deformation is small, and the substrate core board is the selection of Eucalyptus wood is loose, the pores of wood between the loose stress can also be partially offset by an expansion of wood shrink. So its stability is much stronger than other floors.

- Q: Wood composite floor thickness which? Which is better?

- You may also see through the above, in these two kinds of inside, it is obvious that the three layer, the apparent surface of the thickness of your tree is much higher than the multi-storey, so this kind of floor belongs to the top floor;And more than 7 layers, whether it is the 9 or the 11 layer, the relative cost is much lower, so the low-end;

Send your message to us

Best selling ceramic wall tiles in Dubai market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords