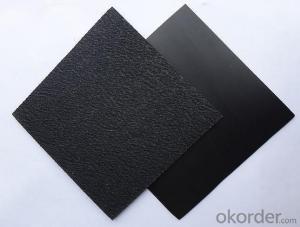

Filtro Geotextil Best Price Low-Density Polyethylene Geomembrane for Reserve Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application

1. high quality hdpe geomembrane use in agriculture

1. high quality hdpe geomembrane use in agriculture farm

3. high quality hdpe geomembrane use in shrimp ponds orLotus

4. high quality hdpe geomembrane use in Slope protection impervious

5. high quality hdpe geomembrane use in Landfill anti-seepage

6. high quality hdpe geomembrane use in Agricultural water reservoir:

7. high quality hdpe geomembrane for roof seepage control

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

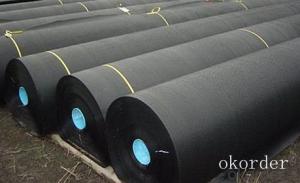

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Artificial lake can not do geotextile waterproofing? What method can not do geotextile waterproof?

- Artificial lake with geotextiles do waterproof? Artificial lake to the bottom of the water leakage. The lake design in the use of geotextile, it is not anti-seepage, it should be used for filtering. There is no use of course there will be different results. If the design has that use. If the lake is to prevent water leakage, there are many ways. 1. Laying a professional anti-seepage geomembrane, composite geomembrane; 2. Laying a layer of sticky heavier little permeability of the clay, pressure solid. 3. There are also laying a layer of geology known as GCL geosynthetics, full name is bentonite waterproof blanket. Geotextile is water seepage, the general is not anti-seepage, can be used to filter. Only in the geotextile composite anti-seepage film to prevent seepage, and composite film after the geotextile has not called geotextile, and should be called composite geomembrane. But because of habitual problems, and now there are people called the seepage geotextile.

- Q: Can geotextiles be used in landfill lining systems?

- Yes, geotextiles can be used in landfill lining systems. Geotextiles are commonly employed as part of the composite liner system to prevent leachate seepage and provide reinforcement. They can act as a barrier between the waste and the soil, reducing the potential for contamination and enhancing the overall performance of the landfill lining system.

- Q: Can geotextiles be used in green infrastructure projects?

- Yes, geotextiles can be used in green infrastructure projects. They are often employed to promote healthier soil conditions, prevent erosion, manage stormwater runoff, and enhance the overall sustainability of green infrastructure systems. Geotextiles can be utilized in various applications such as erosion control blankets, sediment filters, retaining walls, and vegetated roofs, making them an essential component in the implementation of green infrastructure practices.

- Q: Road Central isolation belt (5 m wide) Drainage No design Waterproof geotextile laying and gravel blind ditch, are design flaws?

- Should be it, the general design will have this. If you need to contact me, see the information

- Q: How do geotextiles help in vegetation establishment?

- Geotextiles help in vegetation establishment by providing a stable and favorable environment for plant growth. They prevent soil erosion, retain moisture, and control weed growth. Additionally, geotextiles enhance root development and protect young plants from harsh weather conditions, allowing them to establish and flourish more effectively.

- Q: What is the length of the lap in the geotextile in the tunnel?

- General 20cm can be, I produce geotextile materials

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to prevent soil erosion by stabilizing the soil and promoting vegetation growth. They provide a protective layer that allows water to pass through while retaining soil particles, which helps to reduce erosion. Additionally, geotextiles facilitate the establishment of vegetation by providing a favorable environment for root development. Overall, geotextiles are an effective solution for erosion control in revegetation projects.

- Q: what is the function of geotextiles in footing any photos?

- tis like the subway put some liver in ur mouth In the middle of rush hour whore some year old mayonnaise meets yesterdays tuna It’s end of line.!!!!!!!!

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by providing a barrier between the soil and any applied load or traffic. This helps distribute the load more evenly, reducing the pressure on the soil and minimizing compaction. Additionally, geotextiles can improve soil drainage, allowing excess water to flow away, which also helps prevent compaction.

- Q: Where to sell waterproof geotextile

- Hello, waterproof geotextile is a composite geomembrane if necessary to the Department of Huazhi geotextile material manufacturers to answer the beginning of 135, 4791 last 9192, do not forget Oh

Send your message to us

Filtro Geotextil Best Price Low-Density Polyethylene Geomembrane for Reserve Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords