Best Prepainted Cold Roll Steel Coil Plste JIS G 3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc. composition and form of products EN 754-2: Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties ISO 6361: Wrought Aluminium and

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties EN 755-2: Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles

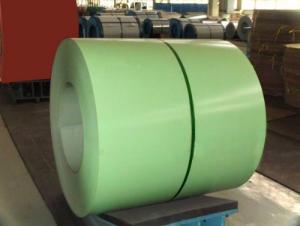

3.Cold Rolled Steel Images

2.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a popular choice for constructing solar panel structures due to its strength, durability, and versatility. Steel sheets can be easily fabricated and shaped to meet specific design requirements, making them suitable for various types of solar panel installations. Additionally, steel has excellent load-bearing capabilities, which is crucial for supporting the weight of solar panels. It is also resistant to corrosion and can withstand harsh weather conditions, making it a reliable material for long-term use in outdoor settings. Overall, the use of steel sheets for solar panel structures is a practical and cost-effective solution.

- Q: How do you cut a steel sheet?

- To cut a steel sheet, you will need to use the appropriate tools and techniques. Here are a few common methods: 1. Power tools: The most common power tool used for cutting steel sheets is an angle grinder equipped with a cutting disc. Make sure to wear safety goggles and gloves while operating the grinder. Mark the cutting line on the sheet using a marker or chalk, then slowly and steadily guide the grinder along the marked line to cut through the steel. 2. Shears: If you are cutting a thin steel sheet, you can use manual or electric shears. These tools have a scissor-like cutting mechanism specifically designed for cutting metal. Place the steel sheet between the blades of the shears, aligning the cutting line with the blades, and apply steady pressure to cut through the sheet. 3. Plasma cutting: This method is best suited for thicker steel sheets. Plasma cutting involves using a high-velocity jet of ionized gas (plasma) to melt and sever the metal. It requires specialized equipment, such as a plasma cutter, which uses an electric arc to create the plasma jet. 4. Waterjet cutting: Another effective method for cutting steel sheets is waterjet cutting. It uses a high-pressure jet of water mixed with an abrasive substance (such as garnet) to cut through the metal. This technique is ideal for complex shapes and precise cuts, but it requires specialized machinery. Before attempting to cut a steel sheet, always prioritize safety. Wear appropriate protective gear, such as safety glasses, gloves, and a face shield if necessary. Additionally, ensure that you are working in a well-ventilated area to avoid inhaling any fumes or particles generated during the cutting process.

- Q: Are steel sheets suitable for HVAC systems?

- Certainly, HVAC systems can make use of steel sheets. Steel sheets are extensively employed in HVAC systems owing to their durability, strength, and corrosion resistance. They contribute to the structural integrity of the system and can endure high temperatures and pressure. Furthermore, steel sheets can be conveniently fabricated and tailored to meet specific requirements of the HVAC system. In addition, they are cost-efficient and have a prolonged lifespan, making them a favored option for components like ductwork, ventilation systems, and air handling units within HVAC systems.

- Q: Are steel sheets suitable for automotive exhaust systems?

- Yes, steel sheets are commonly used in automotive exhaust systems due to their durability, heat resistance, and cost-effectiveness.

- Q: What are the tolerances for steel sheets?

- The tolerances for steel sheets typically depend on the specific industry and application. However, common tolerances for steel sheets are usually specified in terms of thickness, flatness, width, and length. These tolerances can vary but are typically within a few percentage points of the specified dimensions.

- Q: What is the price of each steel sheet?

- The price of each steel sheet may vary depending on factors such as size, thickness, and market conditions. It is recommended to check with suppliers or retailers for current pricing information.

- Q: What are the different sheet metal rolling techniques for steel sheets?

- There are several sheet metal rolling techniques that are commonly used for steel sheets. These techniques include hot rolling, cold rolling, and roll forming. Hot rolling is a process in which steel sheets are heated above their recrystallization temperature and then passed through a series of rollers to reduce their thickness. This technique is commonly used to produce steel sheets with a consistent and uniform thickness. The hot rolling process also improves the mechanical properties of the steel, making it stronger and more ductile. Cold rolling, on the other hand, is a technique in which steel sheets are passed through rollers at room temperature. This process is used to produce thinner and smoother steel sheets with a higher degree of dimensional accuracy. Cold-rolled steel sheets are often used in applications that require a high-quality surface finish, such as automotive body panels and appliances. Roll forming is a continuous bending process in which a long strip of steel is passed through a series of rollers to gradually shape it into a desired profile. This technique is commonly used to produce steel sheets with complex shapes and profiles, such as corrugated roofing sheets or C-channel beams. Roll forming offers excellent precision and repeatability, making it a popular choice for producing large quantities of steel sheets with consistent dimensions. Overall, the choice of sheet metal rolling technique depends on the specific requirements of the application. Hot rolling is ideal for producing steel sheets with a uniform thickness and improved mechanical properties. Cold rolling is preferred for applications that require a high-quality surface finish and dimensional accuracy. Roll forming is suitable for creating steel sheets with complex shapes and profiles.

- Q: What are the different shapes available for steel sheets?

- There are various shapes available for steel sheets, including but not limited to flat sheets, coils, strips, plates, and perforated sheets.

- Q: Excuse me, what's the difference between cold rolled steel plate and hot plate in steel plate?

- In general, cold rolled steel has better strength, hot rolled steel plate has better ductility. The general thickness of cold rolled is relatively small, can have a larger thickness. Cold rolled steel plate surface quality, appearance and dimensional accuracy than the hot plate, and the thickness of the product right rolling thin to about 0.18mm, so it is popular for. The acceptance of the products, can ask professional personage.

- Q: How much is one meter for laser cutting steel plates?

- The length and width are smaller than 300MM and the thickness is less than 12MM, because of good nesting material, we provide. By weight, the carbon steel is 8~9 yuan per kilogram and the quantity is large, 7~8 yuan per kilogram.

Send your message to us

Best Prepainted Cold Roll Steel Coil Plste JIS G 3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 111 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords