Best Non Woven Geotextile Fabric Plastic Deer Fence Net /25g Plastic Mesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

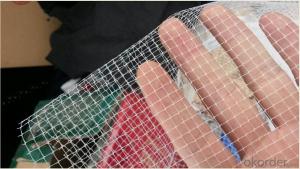

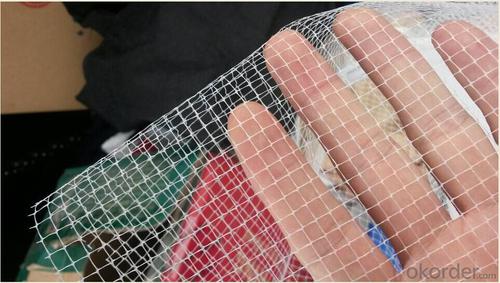

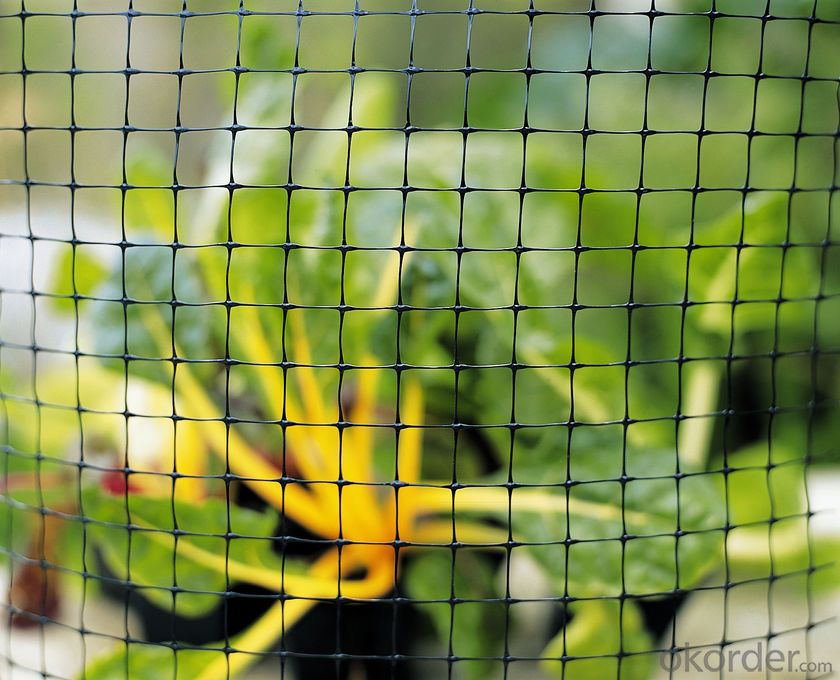

Plastic netting plastic mesh breeding mesh

1. Plastic Plain Netting

Colour:white,black,blue and green, client's requirement.

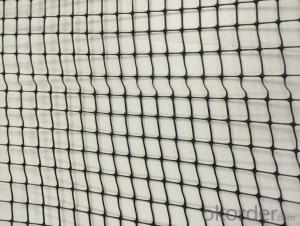

2. Deer fence introduction:

Deer fencing is a very high strength, lightweight, 3.6ft to 7.3ft high deer fence manufactured from high strength polypropylene BOP plastic netting. Deer have a tendency to forage over large areas and the cost effective deer fencing offers a very effective deer control barrier.

The deer fence is black, UV stabilised and rot proof and unobtrusive as it merges into it's background. Deer fencing is very quick and easy to erect and each roll weighs less than 15kg. The Deer Netting should be installed by battening to the fencing posts to ensure the mesh filaments are not damaged.

3. Features of the deer neeting fence:

Deer fence is easy to erect and install

Plastic netting has a mesh hole size of 0.06" ,0.08",0.18",0.19"

The BOP plastic netting has a high tensile strength

Plastic mesh is UV stabilized and chemical resistant

Deer fencing rolls are lightweight

Deer fencing is a very high strength, lightweight 1.8m high Deer fence manufactured from polypropylene.

Deer fencing net is supplied on a 100m long roll

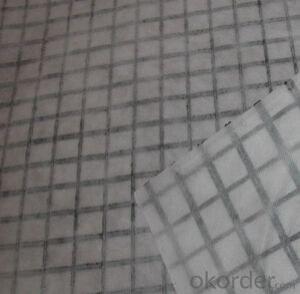

4. Features:

1). Low cost, while has superior strength

2). Has anti-tearing and friction capability

3). Wide range of product availability, some other mesh sizes and weights can also produced as per customers' requirements.

6. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Do you have a drainage board and a geotextile on the basement roof?

- Hello, generally do not require re-test Huazhi geotextile materials, manufacturers need to answer for your needs

- Q: What are the long-term performance expectations for geotextile installations?

- The long-term performance expectations for geotextile installations vary depending on factors such as the specific application, the quality of the geotextile material, and the environmental conditions. However, in general, geotextile installations are designed to provide durable and reliable performance for extended periods, typically ranging from 20 to 50 years. Regular maintenance and monitoring can help ensure that geotextile installations continue to perform effectively over the long term.

- Q: Geotextile in the asphalt layer under what role

- The main role is isolation, drainage. Id phone manufacturers

- Q: What are the key considerations for geotextile installation in high wind areas?

- Some key considerations for geotextile installation in high wind areas include selecting a geotextile with a high tensile strength to withstand the force of the wind, ensuring proper anchoring and securing methods are used to prevent the geotextile from being blown away, and conducting regular inspections and maintenance to identify any damage or potential issues caused by the wind. Additionally, the design and placement of the geotextile should take into account the wind direction and intensity to minimize the risk of wind-related damage.

- Q: Does the color cloth be geotextile?

- Straw, sacks, stone, gravel, wood, steel, color cloth, lighting equipment, transport, alarm equipment, digging tools, lead wire, cement, soil, sand, geotextile and so on.

- Q: What is the difference in role of earth anchors and geotextiles in the construction of retaining wall?

- Geotextiles prevent the infiltration of the natural, insitu soil into sand or structural gravel that you may place as a foundation to the retaining wall. You can think of it as a membrane that keeps the two types of material of different densities, from gradually mixing together. A free standing retaining wall will likely not be successful as the pressure of the retained soil behind the wall will build up due to settlement, and eventually cause the wall to topple. Earth anchors that tie into the wall and extend into the backfill material (retained earth) serves to support the wall and keep it from failing.

- Q: Are geotextiles resistant to creep deformation?

- Yes, geotextiles are generally resistant to creep deformation. They are designed to have low deformation properties under constant or sustained loads, making them effective in preventing or minimizing creep.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavy materials like concrete or steel. Secondly, geotextiles have a high strength-to-weight ratio, providing excellent reinforcement and stabilization capabilities for soil and other materials. Additionally, geotextiles are permeable, allowing for proper drainage and preventing water buildup, which can lead to erosion or structural damage. Moreover, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring their long-term durability. Lastly, geotextiles are cost-effective, as they require less labor and equipment for installation and maintenance compared to traditional materials. Overall, the use of geotextiles offers numerous benefits in terms of efficiency, functionality, and sustainability in construction projects.

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

- Q: Are geotextiles suitable for use in canal lining?

- Yes, geotextiles are suitable for use in canal lining. They provide effective erosion control and filtration, preventing soil loss and allowing water to flow through while retaining fines. Geotextiles also offer durability, resistance to UV degradation, and can be installed easily.

Send your message to us

Best Non Woven Geotextile Fabric Plastic Deer Fence Net /25g Plastic Mesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords