Composite Pipes FRP Grating Pultruded Grating GRP Grating High Quality Fiberglass Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

FRP Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

2. Main Features of FRP Grille

1) Light Weight & High Strength

The perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

2) Electrical Insulating

High strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

3) Aging Resistance

The high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years

4) Safety & Anti-slip

The high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

5) Corrosion Resistance

Different types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

6) Fire Resistance

Our special formula provide grating with excellent fire resistant performance.

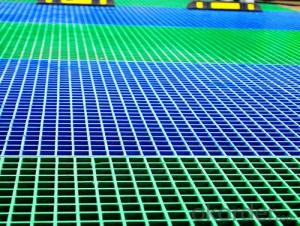

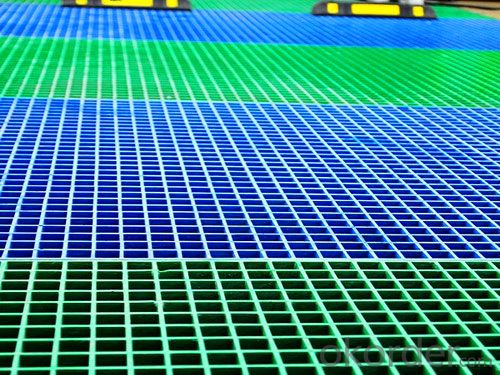

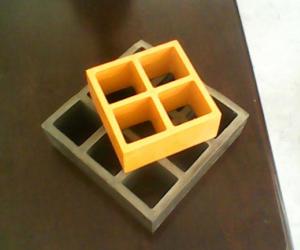

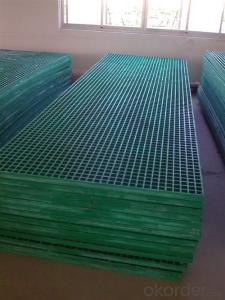

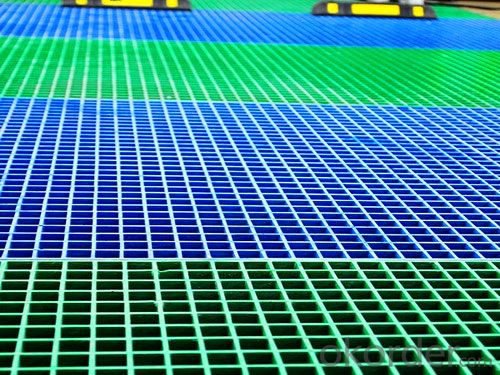

3. FRP Grille Images

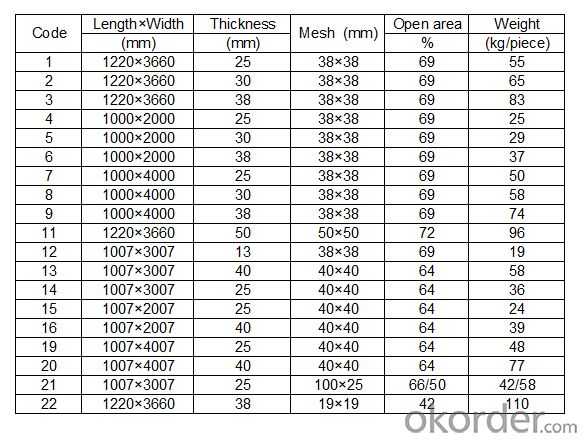

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: The difference between FRP process tubes and GRP tubes

- Process tubes are mostly pure glass steel, not sand, and sand pipe, of course, is added sand.

- Q: Mending method for glass fiber reinforced plastic pipe

- Other repair methods: choose resin, accelerator, curing agent, high quality glass fiber cloth. Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, the proportion of the curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth for glass steel with a good quick, let the glass steel glass fiber cloth fully soaked, waiting for glass steel fully cured, and then repeated several layers. It will be strong.

- Q: Glass fiber reinforced plastic GRE pipe broken hole how to repair and repair?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: CGCT what's the meaning of the GRP sand pipe?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: What can be done to solve the leakage of FRP pipe?

- DN1800 FRP pipe pressure of 9 kilograms, the pressure is very high, crushed by stones, not repaired will certainly leak, the pressure pipe leakage is very bad, will be washed away the soil, spewing a few meters high water column.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- The standard for FRP pipe execution is GB21238-2007

- Q: What's the price of fiberglass reinforced sand pipes?

- This depends on the specific size of the caliber you want, how much thickness, specifically for you to quote. If you have any questions, you can talk to me privately.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

Composite Pipes FRP Grating Pultruded Grating GRP Grating High Quality Fiberglass Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords