Composite FRP Grating Pipes and Fiberglass Grilling Grating Solutions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Grille Description

FRP grating density is about 1.8, is only a quarter of the steel, aluminum two-thirds.10 times the strength of rigid polyvinyl chloride (PVC), absolute strength more than aluminum and the level of the ordinary steel.

Comparing with other floor materials, FRP moulded grating provides a series of benefits, unmatched impact resistance, while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install. FRP moulded grating is made of continuous fiberglass fully soaked in unsaturated polyester resin giving a uniform structure and perfect bi-directional mechanical properties.

Standard resins being used include Orthophthalic, Polyester resin, Isophthalic polyester, Vinyl ester resin. Vinyl ester grating provides extremely high corrosion resistance.The surface of FRP moulded grating can be concave top, flat top, grit top,Decorative Pattern Cover,Grit Cover and Smooth Cover.

2. Main Features of FRP Grille

1) Corrosion and chemical resistant

2) High strength-to-weight ratio

3) Fire retardant

4) Ergonomic

5) Slip-resistant

6) Anti-aging

7) Easy maintenance

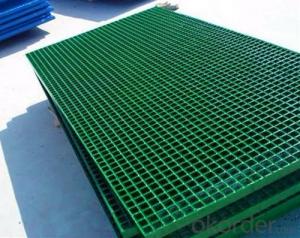

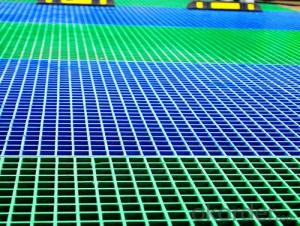

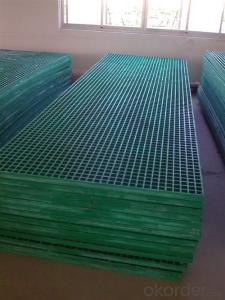

3. FRP Grille Images

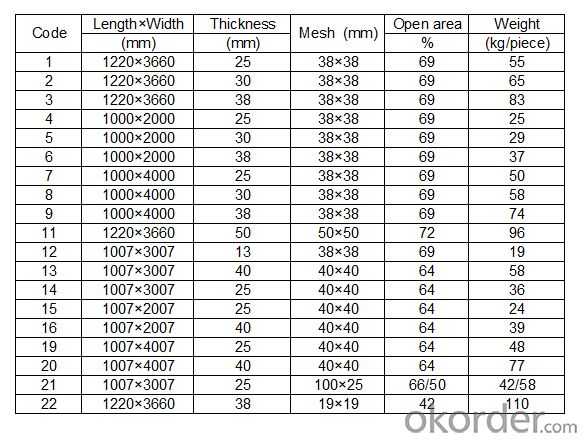

4. FRP Grille Specification

5. FAQ of FRP Grille

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: The difference between GRP cable duct and PVC cable pipe

- PVC cable pipe refers to various kinds of rigid PVC pipes made of PVC resin as main raw material and various stabilizers.

- Q: CGCT what's the meaning of the GRP sand pipe?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high). Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- In brief, the disadvantage of FRP sand pipe is that the pipe is restrained by external environment, such as construction environment and span of support. Used in drinking water engineering, loess and sandy soil in the north are more suitable, but in ponds, marshes, mountains, then the pipeline backfill will increase the project investment. Used for overhead glass steel pipe lines, supporting the size of the gap is also the success or failure of the pipeline.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

- Q: What are the materials used in smoke exhaust pipes?

- The exhaust pipe in the environmental protection system is divided into: suction duct, mine gas drainage pipe, coating cloth cylinder etc. in mine industry and construction industry in the central air conditioning system of factory and office building, with dust, smoke, oil, exhaust pipe, industrial environment with comfortable air supply pipe or post industrial pollution control. The exhaust pipe in accordance with the use of this distinction is several, the exhaust pipe is generally not used in building drainage pipeline in the smoke tube, because the rain is very prone to corrosion of steel, so in general use PC tube drain pipe.

- Q: How can I make up the broken glass fiber?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline. The pipeline in the design according to the use of pressure, stiffness and other conditions to determine the need for sand, if the thickness of the pipe can satisfy the pressure requirements and can meet the requirement of stiffness, is generally not the sand.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: The role of glass fiber reinforced plastic cooling towers

- Thermal power plants usually have cooling towers. Water heating, high pressure gas generated by promoting the steam turbine power generation, and the remaining gas cooling.

- Q: Excuse me, what standard does the glass fiber that check mechanical and electrical use accord with GB?

- FRP insulated pipe is a kind of light, high strength and corrosion resistant nonmetal pipe.

Send your message to us

Composite FRP Grating Pipes and Fiberglass Grilling Grating Solutions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords